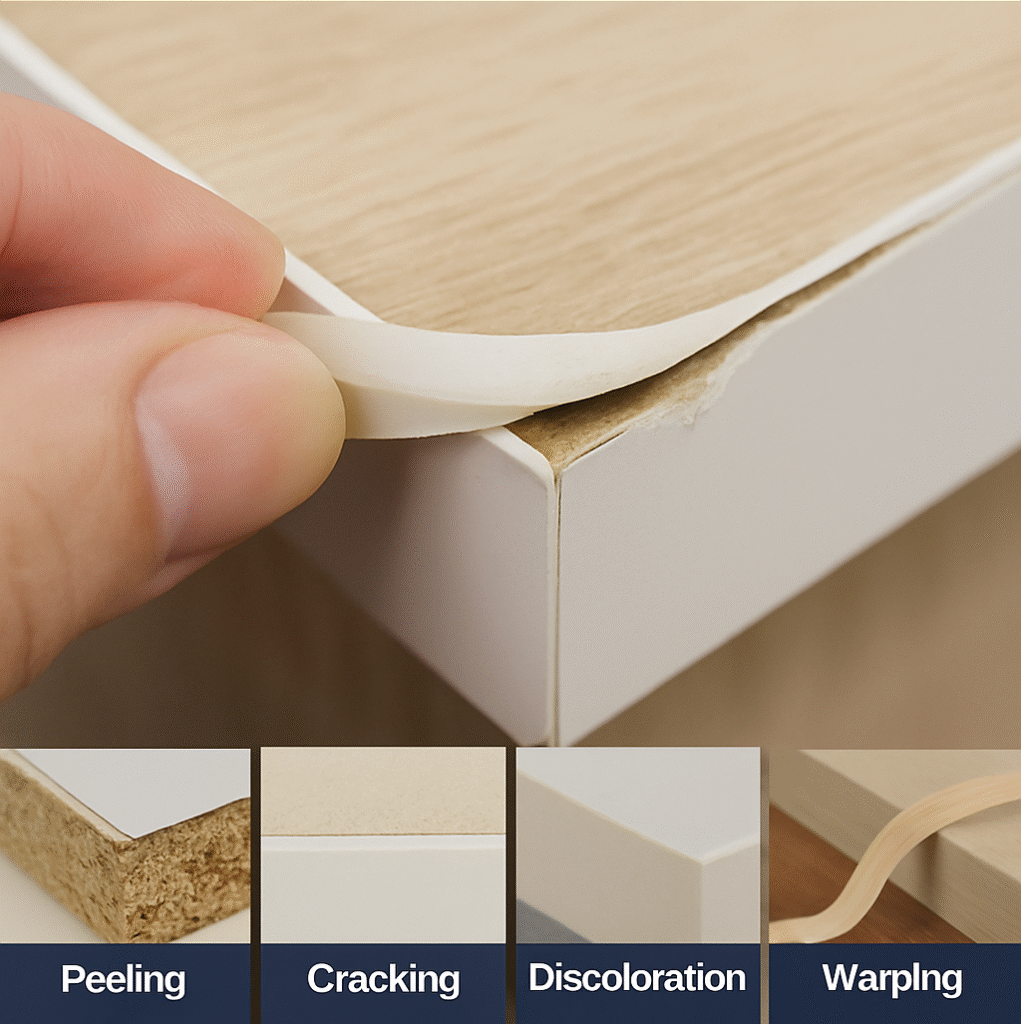

Cheap edge banding may look like a win today — until it peels, cracks, or discolors, leaving your business with lost trust and costly returns.

When you choose low-quality edge banding, you risk product failures that can damage your reputation and increase long-term costs. Quality issues like poor adhesion, inconsistent color, or warping often appear after installation, turning one bad roll into a costly recall.

It might seem like you’re saving money upfront, but what’s the real cost of replacements, complaints, and returns? Let’s break it down.

What Happens When Edge Banding Fails?

Your product may leave the factory looking good — but the problems start once it reaches the customer.

Edge banding failures like peeling, bubbling, and discoloration often show up weeks or months later. These problems don’t just damage the finished product; they damage your customer relationships. For a distributor or importer, this can mean returns, urgent reorders, and higher support costs.

Customers don’t care whether it was the board or the banding. They just see failure — and your brand attached to it. That’s why I learned the hard way to stop choosing edge banding based on price alone.

Why Does Cheap Edge Banding Fail?

| Cause | Effect |

|---|---|

| Low-grade materials | Cracks under heat or cold |

| Inconsistent formulation | Color mismatch with panels |

| Weak adhesive | Peels off after limited use |

| No aging tests | Turns yellow under UV light |

In my early sourcing days, I ordered a container of budget-priced PVC edge banding. It looked fine on arrival, but within three months, my biggest client called: “Your edge banding is yellowing — we can’t sell this.” I had to cover the refund. The money I thought I saved? Gone.

Does Poor Adhesion Really Matter?

Yes — one weak bond can break your entire order.

Adhesion strength isn’t just about glue. It’s about how the edge banding was produced, stored, and shipped. If the material wasn’t cured properly or tested for bonding strength, it may look fine at first — then detach under light pressure or temperature change.

When customers see an edge popping off a drawer, they don’t blame the glue — they blame the supplier.

How to Test for Good Adhesion

| Test Type | What It Shows |

|---|---|

| Peel test | Resistance to separation from substrate |

| Heat aging test | How it holds under long-term heat exposure |

| Cold crack test | Behavior under freezing temperatures |

At CT, we test every batch with real-life conditions: high humidity, sunlight, freezer temperatures. That’s how we ensure our edge banding stays put — even years later.

Can Cheap Edge Banding Match Panel Color?

No — and your customers will notice.

One of the biggest pain points with budget edge banding is color matching. Most budget factories don’t calibrate to major panel brands. That means you’re constantly settling for “almost” matches, which just aren’t good enough.

Your clients expect seamless finishes. If the edge banding is even 2–3% off in tone or gloss, it looks unprofessional.

Why Color Matching Matters in the Field

| Problem | Real-World Result |

|---|---|

| Poor color match | Customers return or reject panels |

| Low gloss consistency | Edge band stands out under lighting |

| No grain alignment | Visual mismatch on textured panels |

We’ve invested in a panel database from the top 20 global brands. Every roll is matched by spectrometer, not by eye. And we’re updating matches every 30 days to follow the latest collections.

What About Long-Term Durability?

Your edge banding must last — not just survive shipping.

Durability isn’t just about avoiding visible cracks. It’s about UV resistance, moisture resistance, and whether the plasticizers inside will degrade over time.

Cheap PVC often contains low-quality fillers. These break down in sunlight, causing yellowing and brittleness in less than a year.

What Should You Ask Your Supplier?

| Question | Why It Matters |

|---|---|

| Do you run anti-yellowing tests? | Verifies UV resistance |

| How many hours of lab aging do you test? | Shows long-term stability |

| What certifications do you hold? | Indicates material safety & reliability |

At CT, we use a QUV Accelerated Weather Tester — the same type used in automotive plastics. Our strips are guaranteed not to yellow for at least 10 years in standard interior environments.

Why Should You Pay More for Better Edge Banding?

Because fixing a cheap mistake is more expensive than preventing it.

When you factor in replacements, shipping delays, and lost trust, high-quality edge banding becomes the cheaper option. It’s not just about materials — it’s about peace of mind.

We’ve helped hundreds of distributors switch from low-grade suppliers to our controlled, tested process. Their returns dropped, customer satisfaction rose, and reorder cycles shortened.

What You Really Get from Premium Edge Banding

| Feature | Value Delivered |

|---|---|

| Fast, repeatable color matching | Reduces return rates |

| Reliable bonding under stress | Avoids failures after install |

| Global certifications | Eases import and resale |

| Batch traceability | Fix problems before they spread |

You don’t need to gamble with quality. Ask us for a sample. Test it. Your customers will notice the difference.

Cheap edge banding isn’t a bargain if it costs you trust, time, and reorders. Choose better now — and build stronger business later.