I worry when I see smart factories miss sales because they stuck to old playbooks. (PAS)

Distributors who adapt to 2025 trends can win more share. Focus on market demand, product customization, digital sales, and partnerships. I explain practical steps to grow.

The market is changing fast. Read on and I will show how I would act if I ran a PVC edgeband distribution business today.

Understanding the 2025 Market Trends for PVC Edgebanding?

Many buyers now expect faster delivery and more options. I saw that shift in the last two years. (PAS)

Edge banding demand grows with furniture production and customization. Market reports show steady growth and rising interest in PET and specialty finishes.

Dive deeper: size, drivers, and where the opportunities lie

Global edge banding materials are growing. Reports estimate the market around USD 1.5–1.6 billion in 2024–2025 and forecast continued growth into the 2030s. PVC still holds a large share of that market, but alternatives like PET and textured finishes are gaining ground. These figures mean demand is not static. It is shifting toward more variety and higher-spec products.

Key drivers I watch:

- Furniture production growth in APAC and Latin America drives volume demand.

- Customization and on-demand variants push demand for short runs and many SKUs.

- Sustainability concerns nudge buyers toward recycled or low-emission products. I see more queries about PVC alternatives and certifications.

Opportunities I would target first:

- Stocking fast-moving standard decors in regional hubs. This cuts lead time and wins orders.

- Offering small-lot custom colors and textured embossing with a clear price model. Many clients will pay a premium for short, accurate runs.

- Adding PET and veneer edges as upsell options for designers who want cleaner aesthetics or eco claims.

I keep a short dashboard for decisions:

| Indicator | Why I track it |

|---|---|

| SKU turnover | Shows which designs need local stock |

| Lead time to client | Directly affects win rate |

| Margin by SKU | Finds profitable custom vs commodity mix |

| Customer requests for sustainability | Signals shift to new materials |

If I were scaling, I would invest early in the SKUs and services that reduce friction for buyers. Quick wins come from faster quotes, reliable samples, and clear shipping windows.

Key Challenges PVC Edgeband Distributors Must Overcome?

I once lost a contract because my quote came too late. Speed matters more than ever. (PAS)

Distributors face tight margins, long supplier lead times, SKU complexity, and rising buyer expectations for service and sustainability.

Dive deeper: concrete pain points and the fixes I use

I break the problem into supply, product, sales process, and talent.

Supply and lead time. Long supplier lead times kill deals. I reduce this risk by holding buffer stock of core decors in local hubs. I also negotiate smaller MOQ (minimum order quantity) runs with trusted extruders. For urgent jobs, I keep a fast lane with a premium supplier.

SKU complexity and inventory cost. Too many SKUs tie up cash. I segment SKUs into core, seasonal, and custom. Core SKUs get local stock. Seasonal SKUs sit at a regional buffer. Custom SKUs use just-in-time ordering with clear lead times and premiums. A simple ABC inventory model helps me decide stock levels.

Quality and consistency. Color or texture mismatch creates returns. I demand COA (certificate of analysis), assembled proofs, and lot traceability from suppliers. I keep a sample passport for each approved board-edge pair.

Digital expectations. Buyers want quick quotes, online catalogs, and real-time stock. I optimize for that by publishing a clean B2B catalog and live inventory. Many digital guides show that inbound marketing works well for manufacturers and distributors. Investing in an eCommerce/B2B portal is often the fastest path to higher repeat orders.

Sustainability and compliance. Some clients demand lower emissions or recycled content. I create green SKUs and add clear labels. That avoids last-minute rejections on tenders.

A practical checklist I use on week one:

| Problem | Immediate fix |

|---|---|

| Slow quote response | Template quotes + pricing tiers |

| Long lead time | Local buffer stock for top 20 SKUs |

| Too many SKUs | ABC analysis and SKU rationalization |

| Quality disputes | Proof & COA requirement |

Tackling these issues makes sales repeatable. It also frees time to pursue bigger customers.

How Product Innovation and Customization Drive Market Growth?

Customers now want unique finishes and short runs. I have seen demand for digitally printed patterns and bespoke colors rise. (PAS)

Customization and small-batch production let distributors charge higher margins and lock in designers. Adding digital printing and fast color matching pays off.

Dive deeper: what to offer, how to price, and the operational steps I take

Customization is not just a feature. It is a margin engine. I focus on three product plays: color-matching services, textured/embossed runs, and short-run digital printing.

Color-matching services. I offer a color passport and physical proofs. I set clear ΔE tolerances and provide a small pilot run. Clients appreciate predictable outcomes and pay for that certainty.

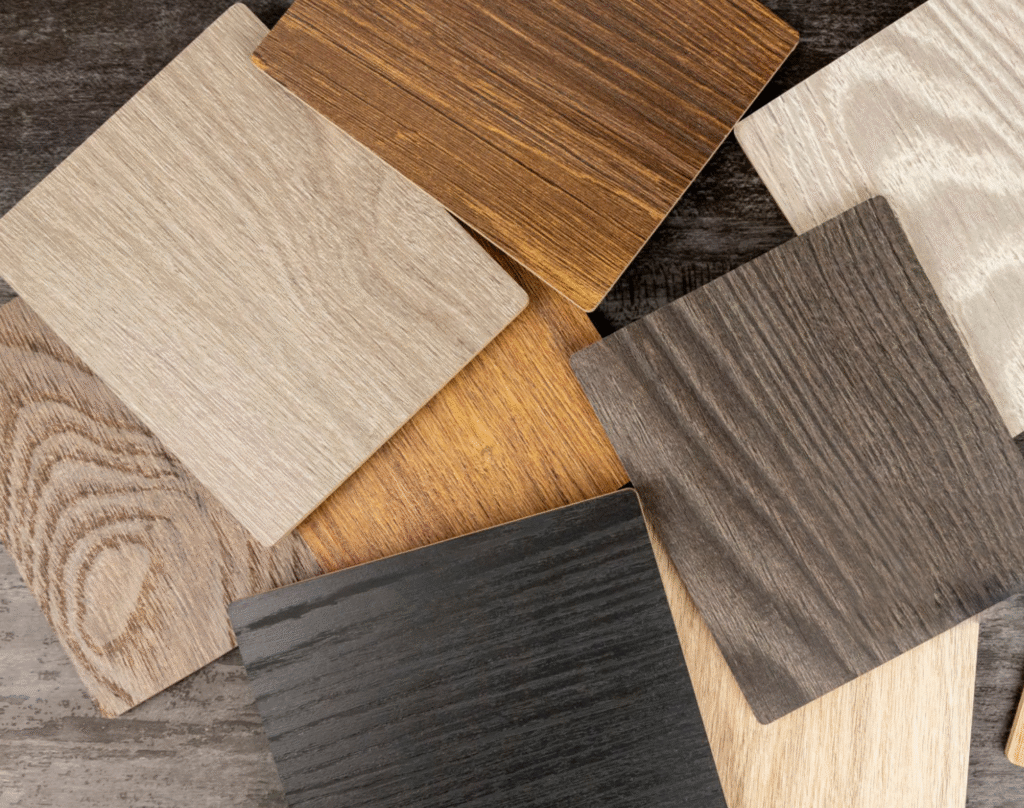

Textured and specialty edges. Micro-embossing and woodgrain textures add perceived value. I partner with extruders who can offer consistent embossing and matched gloss levels.

Digital printing for short runs. Digital printed edges let me offer one-off patterns and rapid restyles. I price digital runs to include setup and a premium per linear meter. The premium offsets the technology and quality control cost. Reports on 3D configurators and personalization show that buyers convert more when they can preview custom options.

Operational steps I implement:

- Build a small sample lab for proofs.

- Price clearly: base price + customization fee + lead time premium.

- Set a minimum pilot length that makes sense for your margin.

- Train a sales rep to explain tradeoffs: lead time, MOQ, and visual proof.

A sample pricing table I use internally:

| Service | MOQ | Typical premium |

|---|---|---|

| Standard stock edge | 1000 m | 0% |

| Custom color match | 100 m | 10–25% |

| Digital printed pattern | 50 m | 25–60% |

| Textured embossing change | 200 m | 15–30% |

Customization drives loyalty. It also helps distributors move from price competition to value competition.

Leveraging Digital Marketing and International Channels to Expand Reach?

I saw leads double after we built a clearer B2B site and started content marketing. That change scaled over months. (PAS)

Digital channels cut friction for buyers. SEO, targeted ads, 3D configurators, and marketplaces help distributors reach new regions and larger accounts.

Dive deeper: the tactics I use and the minimal tech stack to start

Digital is not optional. I recommend a staged approach.

Stage 1 — Foundation. Clean B2B website, live inventory, downloadable technical datasheets, and clear contact paths. Add an HTML catalog with SKUs and pack sizes. This reduces simple rejections and speeds quoting.

Stage 2 — Demand capture. Invest in SEO for queries like “PVC edgeband supplier [region]” and “custom color edgeband.” Publish case studies and spec guides. Use LinkedIn and Google Ads to reach procurement and design leads. Data shows inbound strategies generate strong leads for manufacturers.

Stage 3 — Experience. Add a 3D/AR preview or a configurator that shows board + edge combinations. This tool shortens approval cycles and cuts sample shipping. Reports on 3D configurators show better conversion for configurable furniture.

Stage 4 — International channels. List on relevant B2B marketplaces and partner with local distributors. Use regional warehouses to reduce lead time. I test one region at a time and measure cost per order.

Minimal tech stack I would deploy:

- B2B eCommerce platform with login and price tiers.

- CMS for SEO and case studies.

- Live inventory plugin or integration.

- Simple 3D configurator or AR preview (start with image-based before moving to 3D).

- CRM to track leads and follow-up.

KPIs I track:

| KPI | Goal |

|---|---|

| Lead response time | < 24 hours |

| Quote-to-order rate | increase 10–20% in 6 months |

| Cost per lead | decrease over time |

| Repeat order rate | increase with sample program |

Digital investment is measured. Start small, test, then scale what works.

Building Strategic Partnerships with Furniture Brands and Manufacturers?

I won a major account when I offered joint specs and stock for their top SKUs. Partnerships beat one-off sales. (PAS)

Long-term partnerships secure volume and let you co-develop new decors and finishes. I pursue three partnership types: preferred supplier, co-development, and logistics partnership.

Dive deeper: how I structure deals, what to promise, and the small legal protections to include

Preferred supplier deals. I offer guaranteed service levels for a committed volume. In return I ask for forecast windows and periodic purchase commitments. I include KPIs: on-time delivery, first-pass quality, and sample approval time.

Co-development. We help brands develop exclusive decors, patterns, or textured finishes. I handle prototyping and small pilot runs. Co-development often includes an exclusivity window for certain SKUs. This move creates stickiness and higher margin out of the gate.

Logistics and stock agreements. I offer VMI (vendor-managed inventory) for large customers. I hold stock in their regional warehouse and replenish on consumption. That reduces client lead time and locks in reorder patterns.

Key contract items I add:

- Forecast cadence and rolling windows.

- Acceptance criteria for assembled proofs.

- Penalties or remediation for repeated quality misses.

- Lot traceability requirements for fast root-cause analysis.

A simple partnership scorecard I use:

| Area | Target |

|---|---|

| Fill rate | ≥ 98% |

| On-time delivery | ≥ 95% |

| Quality claim rate | ≤ 1% |

| Forecast accuracy | ± 10% rolling 3 months |

Partnerships cost time, but they create predictable revenue. I prioritize deals where I can add operational value, not just lower price.

Conclusion

I would grow a PVC edgeband business in 2025 by focusing on fast stock, customization, digital sales, and deep partnerships. These moves raise margin and reduce risk.

Data sources and links

- IMARC Group — Edge Banding Materials Market Size, Share Report 2025-33. (IMARC Group)

https://www.imarcgroup.com/edge-banding-materials-market - Coherent Market Insights — Edge Banding Materials Market Size and Forecast 2025-2032. (coherentmarketinsights.com)

https://www.coherentmarketinsights.com/industry-reports/edge-banding-materials-market - Future Market Report — PVC Edge Banding Market Size and Forecast. (Future Market Report)

https://www.futuremarketreport.com/industry-report/pvc-edge-banding-market - IEnhance — The furniture industry’s shift to 3D product personalization (analysis of configurators and AR). (ienhance.co)

https://ienhance.co/insights/the-furniture-industrys-shift-to-3d-product-personalization - Alliance Interactive / Workshop Digital — Guides to digital marketing for B2B manufacturers. (Alliance Interactive)

https://www.allianceinteractive.com/blog/the-complete-guide-to-digital-marketing-for-manufacturers - Distribution Strategy / Optimizing B2B eCommerce for Distributors (report). (Distribution Strategy Group)

https://distributionstrategy.com/wp-content/uploads/2025/04/DSG-Report-Optimizing-B2B-Ecommerce-for-Distributors.pdf