Problem: Bad storage creates returns and waste fast. I see customers lose margin and trust.

Answer: Store PVC edgeband at stable room temp, control humidity, use FIFO, and handle rolls gently to keep quality.

I run a warehouse. I learned the hard way that storage is part of product quality. Poor habits in the warehouse show up as peeling, warps, and color complaints at customer sites. Below I give a step-by-step guide you can use now.

Why Proper Storage Is Critical for PVC Edgeband Quality?

Problem: Many distributors treat edgeband like any other roll stock. That causes hidden damage.

Answer: Proper storage preserves dimensional stability, adhesive performance, and surface finish. This lowers rejects and improves customer satisfaction.

Dive deeper: what quality depends on and what I watch for

I think of storage as the first stage of quality control. If stock sits in the wrong place, the material changes. The adhesive can age. The face film can craze. The roll shape can deform. Each of these effects leads to real problems on the line or in the field.

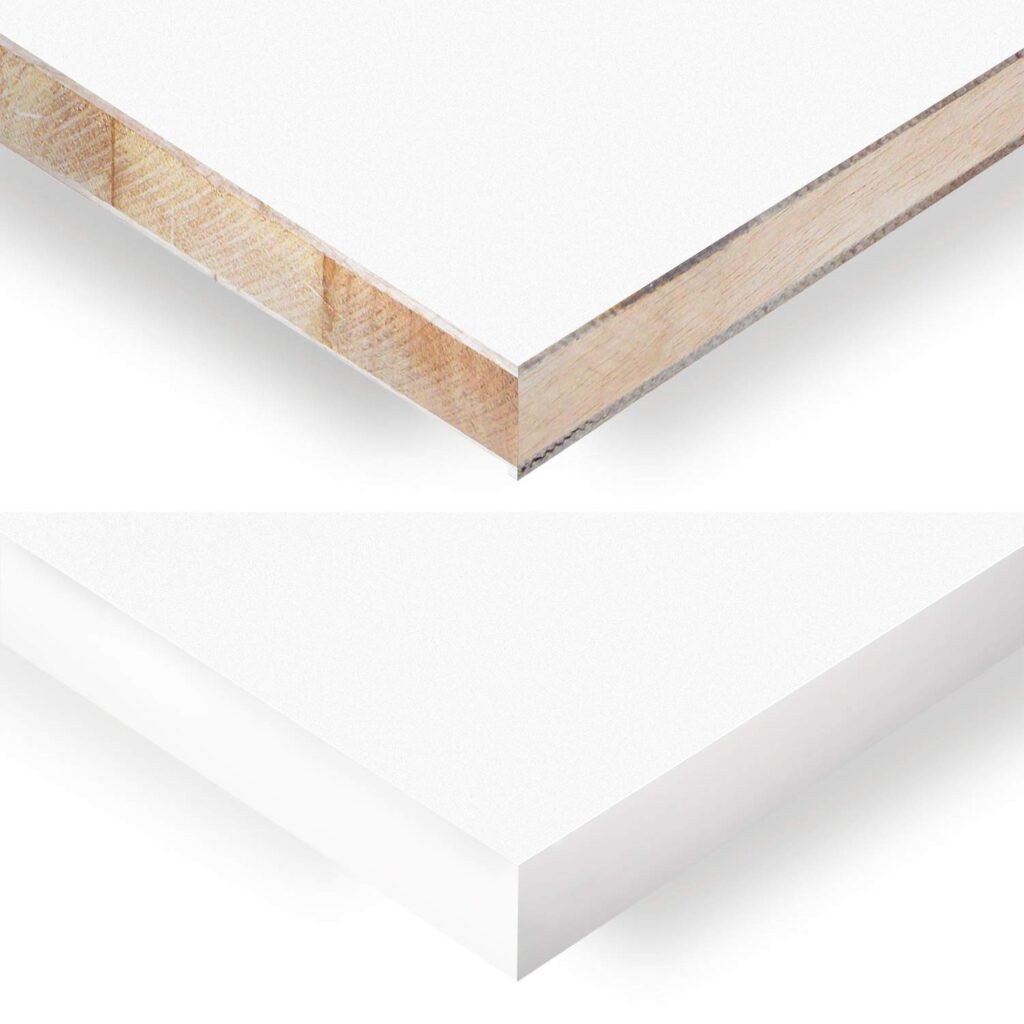

Dimensional stability. PVC is a thermoplastic. It expands and contracts with heat. Long exposure to heat or uneven heating can make thin tapes relax or distort. That makes trimming and edge alignment harder at the customer. I check roll roundness and tape flatness at receipt.

Adhesive health. Many edgebands are pre-coated or use hot-melt glue in production. Heat and humidity affect adhesives. High humidity can cause the glue to skin over or set incorrectly. Heat can speed chemical changes. Both reduce bond strength. I test peel strength on a sample from every new batch.

Surface finish. UV and heat can change color and gloss. Extended storage near windows, open doors, or solvent vapors can alter the surface. I always ask for samples if the color looks off.

Here is a short checklist I use when receiving stock:

| Check point | What I look for | Why it matters |

|---|---|---|

| Roll roundness | No flat spots, no kinks | Prevents feeding problems |

| Surface | No fading, sticky spots | Ensures finish and film health |

| Label / date | Clear manufacture date | Enables FIFO and shelf-life checks |

| Packaging | Intact, sealed film | Limits moisture and contaminants |

I rely on supplier datasheets for recommended storage ranges. Leading makers advise room temp (about 18–25°C) and dry, shaded storage. I follow that. It reduced complaints by a large margin.

Common Storage Mistakes Wholesale Distributors Often Overlook?

Problem: Small habits in the warehouse repeat every day and cause big returns later.

Answer: The top mistakes are: storing near heat or sun, stacking rolls too high, ignoring FIFO, and leaving protective film off.

Dive deeper: typical errors, why they happen, and how I fixed them

I audited our warehouse and found the usual culprits. I list them here and give simple fixes you can apply immediately.

Mistake 1 — Near heat sources or windows.

Why it happens: space is tight and staff put new stock where there is room.

What goes wrong: heat changes the polymer and ages adhesive. It can also cause color shift in decorative surfaces.

My fix: reserve one indoor, shaded bay for edgeband. Use signage and make the area off-limits for other goods.

Mistake 2 — Stacking rolls incorrectly.

Why it happens: to save floor space, teams stack rolls vertically or pile them high.

What goes wrong: flat spots form where rolls contact. This distorts feeding and causes pressure marks.

My fix: use horizontal racks with wide cores. Limit stack height per supplier guidance.

Mistake 3 — No FIFO or date checks.

Why it happens: labels are unclear or staff skip scanning.

What goes wrong: pre-coated or lacquered bands age in storage and then fail at bonding.

My fix: label every roll with receipt date and run a weekly FIFO check.

Mistake 4 — Removing protective film or leaving packaging open.

Why it happens: staff want to inspect visually and leave rolls exposed.

What goes wrong: dust, solvent vapors, and humidity affect surfaces and adhesives.

My fix: inspect quickly and reseal or move to protected area. Keep factory film until ready to use.

| Mistake | Symptom | Immediate action |

|---|---|---|

| Near heat | Color shift, soft rolls | Move to cool bay |

| Bad stacking | Flat spots, feed jams | Re-rack horizontally |

| No FIFO | Old pre-coated use | Start date labeling |

| Open packing | Dust, sticky film | Reseal or quarantine |

I trained staff with photos of bad and good storage. The visual guide helped enforcement. Within a month, rejects dropped noticeably.

Ideal Temperature, Humidity, and Handling Standards for PVC Edgebands?

Problem: Vendors give vague rules. You need concrete ranges for daily use.

Answer: Aim for 18–25°C and 40–60% relative humidity. Keep rolls clean, supported, and away from solvent vapors.

Dive deeper: exact ranges, why they work, and handling notes

I use supplier datasheets and adhesive guides to set warehouse targets. These values balance polymer stability and adhesive health.

Temperature. Most technical sheets from major makers recommend roughly 18–25°C (64–77°F). This range prevents softening and minimizes polymer relaxation. It also keeps adhesive chemistry stable. If warehouse temp goes above 25°C for long, I move stock to cooler zones or use climate control.

Humidity. I aim for 40–60% RH. Low humidity can dry out some adhesives over very long periods. High humidity can shorten open time on hot-melts and cause condensation on cold surfaces. Condensation is a major cause of weak bonds. I use basic hygrometers at key points and log RH twice daily in winter and summer.

Handling. I handle rolls gently. I avoid dropping or compressing them. I store on wide-core horizontal racks. I do not hang thin tapes by their inner core. I keep them in original packaging until use.

Special cases. Pre-coated edgeband and lacquered surfaces have limited recommended storage times. Some pre-coated items need use within 6–12 months. I always check the datasheet and mark expiry on the roll label.

| Parameter | Target | Why |

|---|---|---|

| Temp | 18–25°C | Keeps polymer and adhesive stable |

| Humidity | 40–60% RH | Prevents condensation and adhesive issues |

| Storage | Horizontal on wide core | Prevents flat spots and kinks |

| Packaging | Keep sealed until use | Protects surface and glue |

I place simple thermometers and hygrometers on racks. Staff check them at the start of every shift. This small habit prevents large failures later.

How to Organize and Rotate Edgeband Inventory for Long-Term Stability?

Problem: Mixed lots and poor rotation mean old stock gets used by mistake.

Answer: Implement FIFO, label batches clearly, and store similar types together. Use batch testing for older stock.

Dive deeper: concrete layout, labeling, and SOPs I use

I treat edgeband inventory like perishable goods. The steps below are short and repeatable.

1. Zone by family and finish.

I separate plain PVC, pre-coated, gloss, matt, and specialty films. This prevents accidental mixups. I mark each zone with signs and color codes.

2. Date and batch labeling.

Every roll gets a clear label: supplier, production batch, receipt date, recommended use-by date. I print labels on arrival. Staff scan and log them into our simple inventory list.

3. FIFO lanes on racks.

I allocate front and back positions on each rack. New stock goes to the back. Pickers take from the front. This enforces FIFO and avoids old pre-coated stock being overlooked.

4. Weekly spot checks.

I or a supervisor check 10 random rolls each week. We look for flat spots, damaged packaging, and date compliance. If a roll is older than the recommended shelf window, we run a small test before use.

5. Batch testing for long stock.

If a roll is older than 12 months or outside supplier guidance, I do a bend and bond test before sending it to production. If it fails, I quarantine and contact the supplier.

| Task | Tool | Frequency |

|---|---|---|

| Label rolls | Printed label | On receipt |

| Zone stock | Rack signs | On setup |

| FIFO check | Visual pick | Daily |

| Spot check | Supervisor log | Weekly |

| Batch test | Cold-bend and peel | If >12 months |

I keep a one-page SOP at the rack. It lists how to receive, label, and rotate. New hires learn it in day one. That keeps the system simple and reliable.

Storage Guidelines for Preventing Warping, Color Shift, and Adhesion Issues?

Problem: Even small storage mistakes cause real field failures like warping or peeling.

Answer: Control environment, protect packaging, avoid pressure on rolls, and condition material before use.

Dive deeper: actionable checks and corrective steps I perform

I follow a short checklist before any roll goes to production. This stops most warping, color, and adhesion problems.

Protect from pressure and heat. Never store rolls near boilers, radiators, or oven doors. Keep them off pallet edges and avoid stacking heavy items on top. Use horizontal racks with full support across the roll length. This prevents the tape from taking a permanent set.

Shield from light and solvents. Store in shaded areas. Keep edgeband away from solvent tanks, paint booths, and cleaning stations. Solvent fumes can attack decorative films and adhesives. I move chemical operations to a separate room.

Control stock age of pre-coated tapes. Mark pre-coated rolls with a use-by date according to supplier guidance. Run a quick peel test on older rolls. Many manufacturers set a 6–12 month practical window for pre-coated products.

Condition before processing. Bring rolls and panels into the production area 12–24 hours before bonding. This avoids cold surfaces and condensation. If I cannot pre-condition long enough, I run small test pieces to confirm bond strength.

| Problem | Likely cause | Quick fix |

|---|---|---|

| Warping | Heat or pressure during storage | Re-rack horizontally; reduce heat |

| Color fade | UV or heat exposure | Move to shaded bay; check stock |

| Weak adhesion | Moisture or old adhesive | Condition stock; do peel test |

I record every incident and its root cause. Over time I saw that 90% of warping and adhesion problems came from storage or handling. Correcting these cut my returns and saved time on the line.

Conclusion

I protect PVC edgeband value by controlling temperature, humidity, handling, and rotation. Simple rules prevent most quality failures.

Data sources and links

- REHAU — Edgeband Material, Process and Tips (storage guidance).

https://www.rehau.com/downloads/500572/edgebandmaterialandprocessingtips-100711-rehau.pdf - REHAU — Edgeband Technical Data Sheet (storage temperature limits).

https://www.rehau.com/downloads/886866/edgeband-technical-data-sheet.pdf - EGGER — PVC Edge Banding Technical Datasheet (storage and handling).

https://static.richelieu.com/documents/docsGr/163/252/0/1632520/2616924.pdf - Jowat — Low-temperature Hot Melt Adhesives for Edgebanding.

https://www.jowat.com/en/adhesives/hot-melt-adhesives/jowathermr-eva/low-temperature-hot-melt-adhesives-for-edgebanding/ - ResearchGate — Thermal and Hydrothermal Stability of Hot-Melt Adhesive Compounds (effect of humidity and temperature on peel strength).

https://www.researchgate.net/publication/329988380_Thermal_and_Hydrothermal_Stability_of_Hot-Melt_Adhesive_Compounds_Used_to_Adhere_Plastic_Edge_Banding_Materials_to_Particleboards - Bestin Group — Edge Banding Completed Guide (practical storage and processing tips).

https://www.bestingroup.com/edge-banding-completed-guide/