I see a common problem: cabinets fade or chip within years. I want to show practical fixes and how color matching ties into long-term performance.

PVC edgeband that matches decors keeps cabinets looking whole and protects edges from moisture and wear. Egger offers matched edgebanding for its decors and a large 24+ Decorative Collection that increases matching options.

I will walk you through how PVC protects edges, what material traits matter, why resistance to heat/impact/cleaning extends life, how installation and adhesives matter, and how to evaluate quality before you buy. Read on — the details matter if you want cabinets that last.

How PVC Edgeband Protects Cabinet Edges From Daily Wear and Moisture?

I notice many cabinets fail at the edges first. That worries me because the edge is where moisture and impact meet the panel. If the edge is sealed and matched, the whole piece looks newer longer.

PVC edgeband seals raw panel edges. It stops water from entering the board core and reduces swelling and delamination. Properly matched edgeband also hides small chips so wear is less visible. Egger states they provide matching edge banding for their decorative surfaces.

Dive deeper: How sealing, visual match, and processing combine to protect cabinets

Sealing mechanics and color matching work together. First, PVC creates a physical barrier. This barrier prevents moisture from soaking into particleboard or MDF cores. That lowers the chance of swelling and edge peeling. Second, when the edgeband matches the panel color and texture, scratches and small dents are less obvious. The result is a perceived higher durability.

I break the protection role into three parts:

1) Physical moisture barrier

- PVC is non-porous when manufactured correctly.

- Edge sealing limits capillary action into the board core.

- Good seaming at ends and corners is crucial; gaps ruin the seal.

2) Mechanical abrasion resistance

- PVC tape resists small impacts and repeated contact.

- Thicker edge banding can absorb more energy before cracking.

- Surface texture affects scratch visibility.

3) Visual continuity

- A color and texture match hides wear better than a contrast edge.

- Synchronised textures (grain direction alignment) keep wear patterns subtle.

| Factor | Why it matters | Practical tip |

|---|---|---|

| Seal quality | Prevents moisture ingress | Use continuous application, check for bubbles |

| Thickness | Affects impact absorption | Choose thicker tape for high-contact edges |

| Texture sync | Hides scratches | Match grain direction when possible |

| Color match | Reduces visibility of chips | Use manufacturer-matched edgeband for best results |

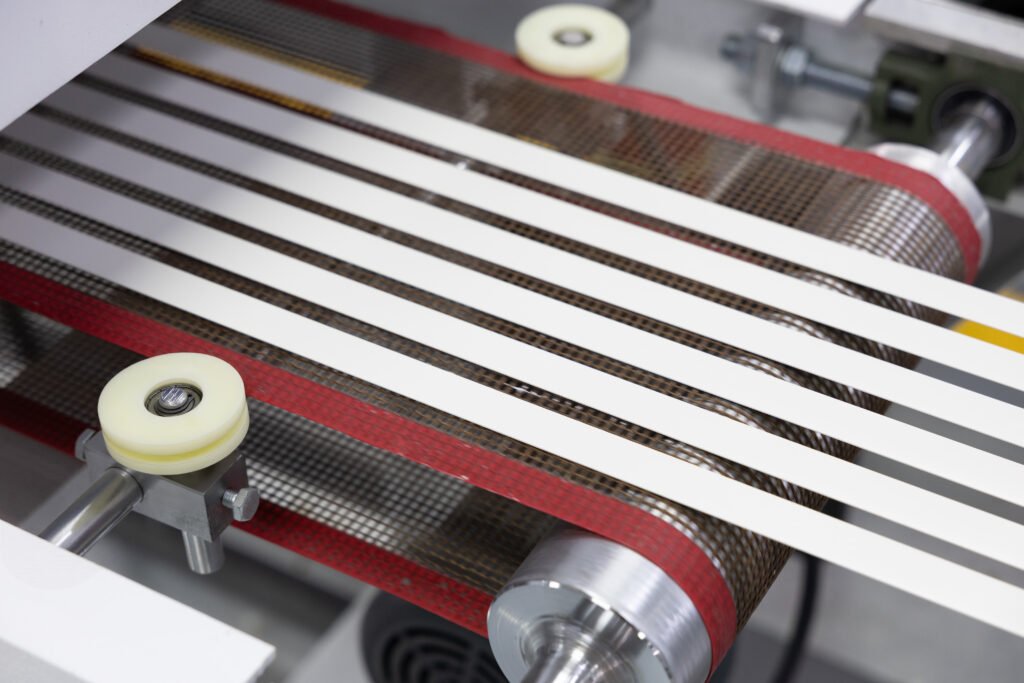

Processing also matters. Heat application and pressure during edge banding must be correct. If you overheat, adhesive can flow and create weak zones. If you underheat, the bond will be poor and the seal will fail. I always test a sample joint with the chosen panel and edgeband before full production.

Material Properties That Make PVC More Durable Than Other Edgebanding Options?

I used to assume all edgebands act the same. I learned they do not. PVC has a particular mix of flexibility and toughness that fits kitchen use.

PVC offers a balance of flexibility, chemical resistance, and ease of processing. Compared with ABS or wood veneer, PVC resists water and common household cleaners better. Suppliers and matching programs now offer wide color options tied to decor collections.

Dive deeper: Material science and trade-offs (mechanical, chemical, thermal)

I break material choice into clear metrics: flexibility, hardness, chemical resistance, thermal tolerance, and manufacturability.

Flexibility and recovery

PVC bends around small radii without cracking. That helps with curved cabinet edges. ABS is stiffer; veneer cracks easier on tight radii. Flexible PVC recovers from light dents better, which reduces visible damage over time.

Hardness and abrasion

Hardness affects scratch resistance. PVC used for edgebanding can be formulated with fillers to increase surface hardness. Surface finish (matt, gloss, wood grain) also affects apparent scratch visibility. Veneer can show scratches more easily because damage breaks through the thin wood layer.

Chemical resistance

Kitchen cleaners, oils, and steam are daily exposures. PVC resists many common solvents and detergents. Veneer finishes and some low-cost laminates can be sensitive to strong cleaners. That means PVC keeps appearance longer with normal maintenance.

Thermal tolerance

Hot pans and steam can affect adhesives and edges. PVC tolerates everyday kitchen heat, but extremes (direct contact with very hot objects) can soften the tape or affect the glue line. ABS has different thermal behavior; some ABS formulas handle heat well, but matching and availability vary.

Manufacturability and color matching

PVC edge tapes are easy to extrude in many decors. This allows close color and texture matches to large decor collections such as Egger’s 24+ range. A supplier who stocks matched edgeband reduces on-site color correction and rework. Having a matched tape reduces visible seams and improves perceived durability.

Trade-offs

- Veneer gives a real wood look but needs more care and is less water resistant.

- ABS is lighter and sometimes more eco-friendly at end-of-life, but color ranges may be smaller.

- PVC balances cost, performance, and matchability for most kitchen cabinet uses.

I recommend testing each material with the exact panel finish and the adhesives you plan to use. Real-world samples reveal the small differences that matter over years.

Why Heat, Impact, and Cleaning Resistance Extend the Life of Kitchen Cabinets?

I often see cabinets degrade from everyday stress: hot steam, boiling water, utensils banging edges, and weekly cleaning. These add up quickly.

Resistance to heat prevents softening and glue failures. Impact resistance prevents chips. Cleaning resistance avoids finish breakdown. Together, they keep cabinets structurally sound and visually consistent. Egger and distribution partners emphasize matched edgebanding to protect against those factors.

Dive deeper: Mechanisms of failure and how resistance reduces long-term repair costs

I think of three daily stress types and their failure modes.

1) Thermal and moisture cycles

- Kitchens have repeated cycles: steam, hot pots, cooling.

- Heat can soften glue lines and change tape stiffness.

- Moisture plus heat accelerates delamination.

- Choosing a tape and adhesive rated for kitchen temperatures reduces these failures.

2) Mechanical impact and abrasion

- Drawer edges and cabinet corners get kicked, bumped, and scraped.

- Repeated low-energy impacts create micro-cracks that grow.

- A slightly tougher PVC or thicker tape will resist micro-cracking.

- Rounded edge profiles distribute impact forces better than sharp edges.

3) Chemical and cleaning exposure

- Cleaners can break down finishes and adhesives.

- Abrasive pads remove surface layers; solvents can blister coatings.

- A chemically resistant PVC surface keeps gloss and texture longer.

- Use recommended cleaning agents and avoid strong solvents near edges.

| Stress type | Failure mode | What to specify |

|---|---|---|

| Heat/steam | Glue softening, delam | Heat-resistant adhesive, test at 60–80°C cycles |

| Impact | Chips, cracks | Higher tape thickness, rounded profiles |

| Cleaning | Finish loss, staining | Chemically resistant surface, test cleaners |

I test samples under simulated stress before specifying materials. That means alternating hot-steam exposure, impact drops, and chemical wipes. These tests help me predict which combinations will survive 3–5 years without repair. Matching edgeband reduces visual repairs because chips blend in. Suppliers with wide matched ranges lower rework when a panel runs out of stock.

Installation and Adhesive Factors That Strengthen PVC Edgeband Performance Over Time?

A good material can fail with poor installation. I have seen perfect tape peel off because of wrong glue or bad temperature. Installation matters as much as material.

Correct adhesive choice, heater settings, pressure, and end finishing determine long-term bond strength. Many manufacturers pair specific hot-melt adhesives with their edgebands for best results.

Dive deeper: Adhesive chemistry, process control, and QA checks

Adhesive chemistry and processing control are the backbone of a long-lasting edgeband. I separate the topic into adhesive selection, machine settings, and QC.

Adhesive selection

- Hot-melt EVA adhesives are common and cost-effective.

- PUR adhesives offer higher temperature and moisture resistance. They are better for humid kitchens.

- Some adhesives are tailored to PVC; others work across PVC and ABS.

- Choose adhesives that match supplier recommendations and the panel core material.

Machine settings and process

- Temperature: Glue must melt but not burn. Too hot degrades polymer chains; too cold yields poor flow.

- Pressure: Proper pressure ensures a continuous glue line and prevents gaps.

- Speed: Fast passes demand different adhesive behaviors than slow runs.

- End trimming and corner finishing: Clean trimming prevents exposed glue or sharp edges that catch.

Quality control

- Bond tests: Peel and shear tests on sample strips reveal initial bond strength.

- Environmental cycling: Repeated wet/dry and heat/cool cycles find weaknesses.

- Visual checks: Alignment, gaps, and bubbles show immediate problems.

| Step | Key control | Field test |

|---|---|---|

| Glue selection | Match to material & humidity | Peel test after 24h |

| Temperature | Use supplier ranges | Check glue bead flow |

| Pressure & speed | Tune to tape thickness | Observe for bubbles |

| End finishing | Proper trimming & sealing | Manual pull test at corners |

I always run a 24–72 hour cure and a basic peel test before shipping. For projects in humid regions I prefer PUR glue. I also insist my line operators log temperatures and speeds so I can trace problems later.

How to Evaluate PVC Edgeband Quality Before Purchase for Long-Term Stability?

Buying the cheapest tape can cost more later. I use a short checklist before I buy edgeband. Matching to the decor is only the first box.

Check match accuracy, thickness tolerance, adhesive recommendations, and stock availability. Suppliers that advertise matched collections for major decor lines are easier to work with. Frama-Tech and other distributors now publish matched Egger collections to simplify selection.

Dive deeper: Practical acceptance tests and supplier criteria

I list the steps I use to evaluate a new edgeband supplier and product.

1) Color and texture match

- Ask for a physical sample and compare under real light.

- Check grain direction and finish type (matt, gloss, super-matt).

- Digital pictures are not enough for final approval.

2) Dimensional tolerances

- Measure thickness and width. Variations affect application.

- Tighter tolerances reduce trimming waste and rework.

3) Adhesive pairing and instructions

- Supplier should recommend adhesives and machine settings.

- Ask for a technical data sheet and test results.

4) Environmental and durability tests

- Request or run peel tests after humidity/temperature cycling.

- Run abrasion tests if possible.

5) Stock and lead time

- Large decor collections (Egger 24+) mean many decors to match.

- Choose a supplier with stock or short lead times to avoid delays.

6) Certifications and sustainability

- Check for relevant certifications if that matters to your clients.

- Some customers value recycled content or lower-emission manufacturing.

| Acceptance step | Minimum requirement | Red flag |

|---|---|---|

| Physical sample | Two samples under different lights | Only digital proof |

| Tolerance | +/- 0.05 mm thickness | No tolerance data |

| Test data | Peel & humidity cycle | No data provided |

| Stock | Local or regional stock | Long lead times without notice |

I always log supplier test sheets and keep a sample chain. That chain helps me match replacements years later. If a supplier claims to match a major decor line like Egger, I verify with their published edgebanding program and ask for joint samples.

My insight

I believe the best outcomes come from pairing the right material with disciplined process control. A perfectly matched PVC tape only shows its value when it is applied with the right glue, correct machine settings, and tested under expected kitchen conditions. I prefer to treat edgeband selection as a systems problem, not a commodity buy.

Conclusion

I recommend matched PVC edgeband, correct adhesive choice, and simple acceptance tests to secure long-term cabinet durability.

Data sources and links

- EGGER PVC Edge Banding — Egger official product page. https://www.egger.com/en/furniture-interior-design/products/pvcedging?lci=Y29sbD0xNjU1Jm5jPW5hdzEg (egger.com)

- EGGER Decorative Collection 24+ — Egger overview of the 24+ Decorative Collection. https://www.egger.com/en/furniture-interior-design/decorative-collection/?lci=bmM9bmF3MSAg (egger.com)

- Frama-Tech: New Egger Edgebanding EDC 24+ Collection announcement (distributor summary). https://www.framatech.com/blogs/the-ultimate-edgebanding-resource-hub/new-egger-edgebanding-edc-24-collection (Framatech)

- Ledgeband — Egger color-matching PVC edge banding product listing. https://ledgeband.com/collections/egger-color-matching-pvc-edge-banding (Ledgeband)

- PRI Edge Banding program notes (comparison of materials and matching). https://priedgebanding.com/eggers-program/ (Priedge Banding)