Problem: I see buyers struggle with off-color or delayed PVC edge banding.

Agitate: Custom colors can cost time, money, and customer trust if done wrong.

Solve: I will show what a good factory should offer to make OEM and color work smooth.

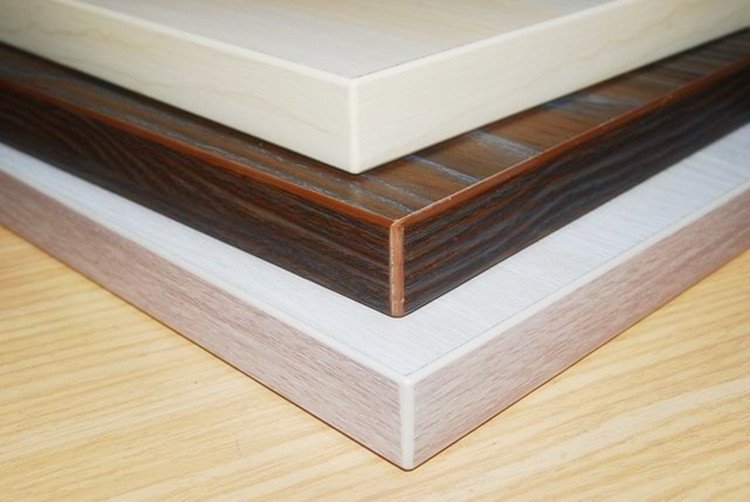

OEM and custom color services are essential for distributors and manufacturers who want consistent, high-quality PVC edge banding. A capable factory reduces sample rework, ensures color accuracy, and supports large-scale production.

If you want smooth custom orders without wasted time, you need to understand the factory’s capabilities, process, and quality control. Keep reading.

Why OEM and Custom Color Services Matter for PVC Edge Banding Buyers?

Problem: Many buyers think any PVC factory can handle custom colors.

Agitate: Choosing the wrong factory leads to inconsistent colors, delays, and extra costs.

Solve: I explain why strong OEM and color services are crucial.

Short answer: A factory with proper OEM and custom color services ensures the product meets exact design specs, reduces sample iterations, and keeps production on schedule. It directly affects profit and client satisfaction.

Dive deeper

Consistency is King

A factory with robust color management can maintain consistent color across batches. Without this, every order risks variation. In my experience, off-color batches cost weeks of rework and lost trust.

Speed Matters

OEM and color-ready factories have systems for quick sample approval and fast production. They can handle small custom runs efficiently while scaling up for bulk orders.

Cost Impact

Errors in color matching or OEM design increase costs. Each extra sample round adds material, labor, and shipping costs. Efficient factories reduce iterations and keep costs predictable.

Table — OEM & Custom Color Benefits

| Feature | Benefit | Example |

|---|---|---|

| Dedicated color lab | Fast and accurate matching | Single round of sample instead of three |

| In-house tooling | Quick OEM adaptation | Custom profiles ready in days |

| Batch tracking | Consistent color across orders | Same shade across multiple shipments |

| Technical support | Helps with design and production | Avoids mistakes in specifications |

A strong factory ensures color and design integrity from first sample to large-scale production. Choosing this right partner saves money, time, and stress.

How to Evaluate a Factory’s OEM Capabilities Before Placing an Order?

Problem: Not all factories can handle OEM requests effectively.

Agitate: A factory without proper OEM setup wastes time, money, and produces inconsistent results.

Solve: I show the key factors to check before ordering.

Short answer: Verify a factory’s experience, tooling capacity, technical support, and past OEM projects. Ask for references and samples to confirm reliability.

Dive deeper

Key Factors to Check

- Experience: Look for factories that have handled multiple OEM orders in your industry.

- Tooling and Equipment: Proper extrusion, embossing, and printing equipment speeds up custom runs.

- Technical Support: Factories should guide on design adjustments, tolerances, and color choices.

- Reference Projects: Ask for images, customer feedback, or case studies.

Table — Factory Evaluation Checklist

| Factor | What to ask | Why it matters |

|---|---|---|

| Experience | How many OEM projects? | Reduces learning curve errors |

| Tooling | Can you produce custom profiles? | Ensures feasibility |

| Sample support | How fast is sample approval? | Reduces lead time |

| References | Can you show past work? | Verifies quality and reliability |

I personally request a trial order to see their workflow. It exposes gaps early and prevents larger issues later.

Understanding Color Matching Processes and Standards in PVC Edge Banding

Problem: Color looks different on screen, sample, and production batch.

Agitate: Misunderstood color standards cause repeated sample runs and wasted material.

Solve: I explain how color matching works and what standards matter.

Short answer: Good factories follow standardized color systems like RAL or Pantone and have a lab to check color under multiple lighting conditions. This ensures accuracy and consistency.

Dive deeper

How Color Matching Works

Factories mix masterbatches according to target codes. They produce a sample for approval, and batch records track the recipe.

Common Challenges

- Different lighting conditions affect perception.

- Small changes in extrusion speed or temperature can alter color.

- Embossed textures may appear darker or lighter than flat samples.

Table — Color Matching Checklist

| Step | Why | Tip |

|---|---|---|

| Masterbatch selection | Base color consistency | Request code reference |

| Sample extrusion | Approve before full run | Use same equipment/settings |

| Lab testing | Verify under different lights | Compare with physical reference |

| Batch tracking | Replicate color for bulk orders | Record masterbatch and process |

Understanding the process reduces trial-and-error and ensures first-run success.

Tips to Reduce Sample Rework and Production Delays in Custom Orders

Problem: Rework delays shipments and raises costs.

Agitate: Many buyers face multiple sample rounds due to unclear specs or miscommunication.

Solve: I share strategies to cut unnecessary iterations.

Short answer: Clear specifications, physical references, and early communication with the factory reduce rework. Proper planning prevents production delays.

Dive deeper

Best Practices

- Provide physical color samples or high-quality swatches.

- Specify exact thickness, width, and edge profile.

- Approve sample officially before bulk production.

- Maintain direct communication with production staff.

Table — Sample Rework Avoidance

| Action | Result | Example |

|---|---|---|

| Provide physical sample | Reduce color mismatch | First sample approved immediately |

| Confirm profile & size | Prevent tooling errors | Correct profile first run |

| Document approval | Avoid disputes | Signed approval reduces confusion |

| Communicate daily | Catch issues early | Messages clarify adjustments quickly |

Following these steps saves weeks of back-and-forth and material waste.

How Quality Control Ensures Consistent Color Across Large PVC Edge Banding Batches

Problem: Even approved samples can vary in bulk production.

Agitate: Variations increase waste and customer complaints.

Solve: I show how QC maintains consistency.

Short answer: In-process inspection, batch tracking, and pre-shipment checks ensure uniform color and quality across all meters produced.

Dive deeper

Key Quality Control Measures

- In-process inspection: Check thickness, adhesion, and color every few meters.

- Batch labeling: Track masterbatch used in each roll.

- Pre-shipment inspection: Verify approved color, embossing, and packaging.

Table — Quality Control Checklist

| Checkpoint | Frequency | Why |

|---|---|---|

| Thickness & width | Every 500–1000 m | Prevents installation issues |

| Color | Each batch | Maintains visual consistency |

| Adhesion | Random sample | Ensures performance |

| Packaging | End of production | Avoid damage in transit |

I once managed a 5,000 m custom order. Continuous QC kept all rolls uniform. It saved time, rework, and avoided client complaints.

Conclusion

A capable PVC edge banding factory offers strong OEM support, precise color matching, minimal sample rework, and reliable QC, ensuring smooth custom orders and consistent quality.

Data sources and links

- Color matching and masterbatch references: https://www.pantone.com/

- PVC edge banding manufacturing guidelines: https://www.made-in-china.com/

- Industry OEM and QC practices: https://www.alibaba.com/