I felt the pain of a bad supplier once — late shipments, peeling edges, and empty promises. I learned the hard way.

Quick answer: Unreliable PVC edge banding suppliers show patterns: dodgy transparency, inconsistent samples, weak QC, sketchy finances or paperwork, and evasive communication. I’ll explain how to spot them and what to do next.

Before you read on, stay with me. I’ll walk you through real warning signs and give steps you can use right now to avoid costly mistakes.

How to Recognize Early Warning Signs of an Unreliable PVC Edge Banding Supplier?

I once got a glossy company brochure that hid a lot. That brochure taught me to watch first impressions closely.

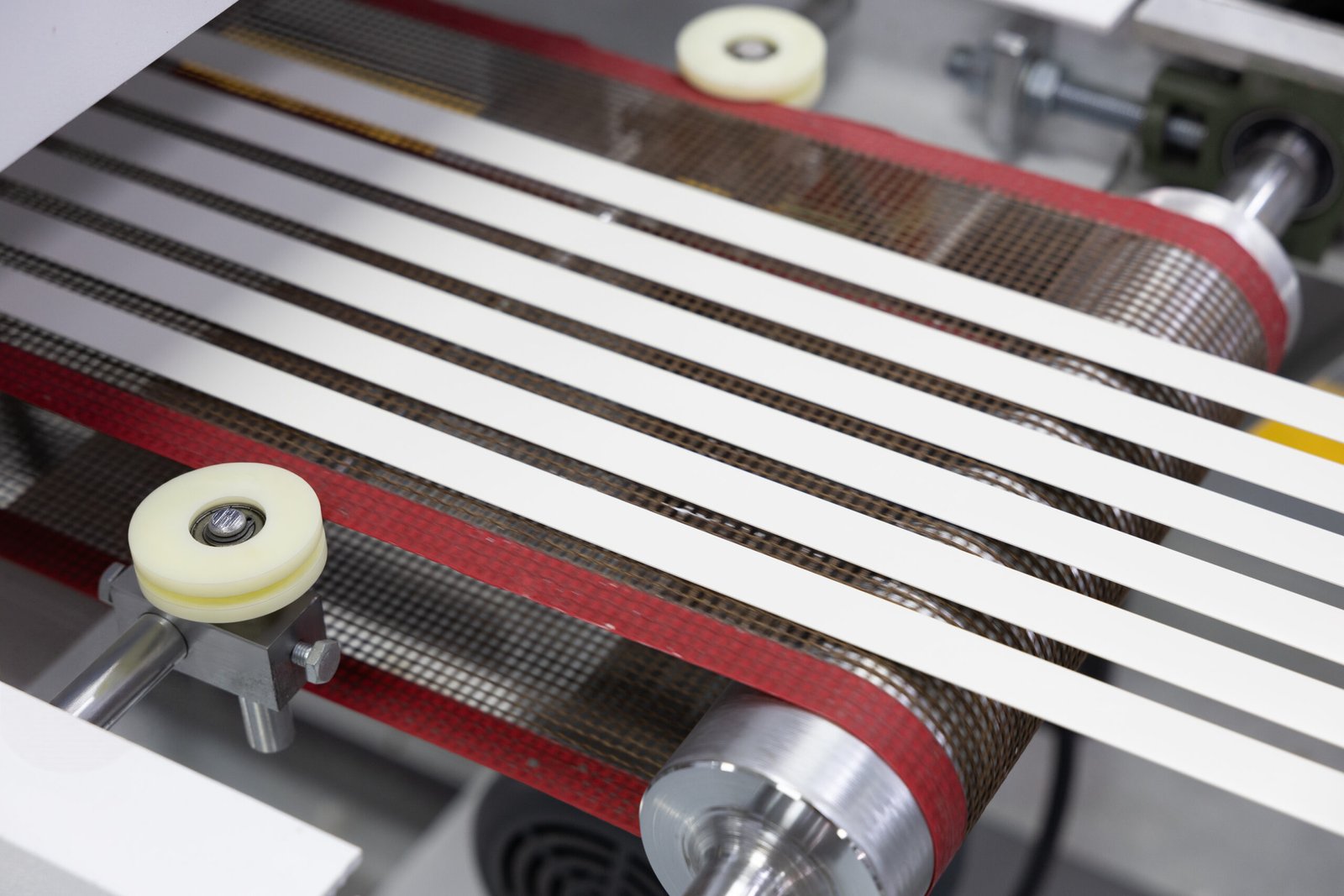

Bad suppliers often dodge simple questions. They refuse live factory video, give vague capacity numbers, or avoid giving traceable references. If they can’t or won’t show you their production lines, I treat that as a serious warning. Transparency is a basic test.

%factory transparency video call

Dive deeper: what early signals mean and how to check them

Early warning signs are small, but they predict big problems. I break them down and show how I test each one.

1. Vague or evasive answers

If a supplier answers slowly, says “we’ll check” without follow-up, or gives canned replies, I mark that down. Real manufacturers answer specific questions about lines, capacity, and raw-material sources. Ask for exact monthly output (in meters or rolls), not vague statements like “large capacity.” If numbers don’t match photographed machinery or other claims, that’s a red flag. Practical check: ask them to show one machine producing your color or profile on a live video call.

2. Refusal of samples from actual production

Some suppliers send “perfect” samples that are hand-picked. I always ask for samples from current production batches and from different rolls. If they refuse, they may be hiding variability. I also ask for technical data sheets (TDS) and adhesive test reports. If they can’t provide lab data or refuse to let an inspector test samples, I move on.

3. Fake or unverifiable certifications

Certificates can be forged. I check certification IDs, certifying body websites, and expiry dates. I also run a quick search for the cert number or ask the cert body for confirmation. If the supplier resists allowing independent checks, I treat it as a major warning. For product-level certifications (e.g., formaldehyde limits, RoHS-like standards), ask for recent lab reports from reputed labs such as SGS or Intertek.

4. Inconsistent photos and stock images

I reverse-image search their photos. If the same factory photos appear under different company names, that suggests trading/reselling rather than actual manufacturing. Real factories usually have up-to-date, unique images and can show video of lines in operation. Practical tip: request a short video showing the product roll number, date stamp, and the machine producing it.

Quick checklist (table)

| Sign | Why it matters | What I ask |

|---|---|---|

| Evasive replies | Shows poor process or unwillingness to commit | “Show me current production video” |

| Special sample only | Hides real quality | “Send sample from last week’s batch” |

| Unverifiable certs | Risk of non-compliance | “Provide cert number and lab contact” |

| Stock photos | May be trading company | “Show raw material receipt and production video” |

Common Quality and Production Red Flags You Should Never Ignore?

I used to accept “good enough.” Not anymore. Quality issues compound fast and ruin margins.

Look for recurring defects: edge peeling, color drift across rolls, uneven thickness, and adhesive failure. If a supplier has repeated complaints or can’t show improvements after feedback, they are unlikely to be reliable. Industry write-ups and sourcing guides warn that persistent defects and lack of corrective action are classic red flags.

Dive deeper: production issues, CQI and how to demand proof

Production problems reveal whether a supplier understands their own process. I split the problems into cause, indicator, and what I require to accept them.

Common problems and what they mean

- Adhesive peel or delamination — Often caused by wrong adhesive type or poor bonding parameters. Ask for adhesive technical data and peel-strength test results.

- Color inconsistency — Means poor pigment control or bad color matching protocols. Ask for Delta E test results and color control procedures.

- Thickness and profile variance — Poor die maintenance or lack of automated controls. Request measurement logs for recent batches.

- Edge finishing defects (nicks, chips) — Could be poor slitting knives or bad handling. Ask for QA checklists and photos of QC in-process.

How I verify production competence

- Request QC logs: Ask for in-process inspection records for a recent order. A serious supplier keeps simple records — dates, inspector name, defects found, actions taken. If they have nothing, that’s a problem.

- Batch traceability: I require the ability to trace material to batch numbers. This helps if a recall or complaint occurs.

- Third-party inspections: For new suppliers, I insist on a pre-shipment inspection by a trusted inspector. If a supplier resists, I cancel.

Structured view (mini table)

| Issue | Likely root cause | Proof I demand |

|---|---|---|

| Delamination | Wrong adhesive/curing | Peel test report, TDS |

| Color drift | Poor pigment control | Delta E report, batch photos |

| Dimensional variance | Worn tooling | Machine maintenance log |

| Repeated customer complaints | Poor CAPA | Corrective action reports |

I don’t accept excuses. I ask for evidence. If they can fix the problem and show records, I consider a trial order with strict QC terms.

Hidden Operational Issues That Reveal a Supplier Is Not Trustworthy?

I once discovered a supplier was a reseller, not a factory. That changed everything.

Operational red flags include inconsistent facility claims, absent production records, and dependence on “supervision” visits from the trading office. If key operational details are missing, your supply will be fragile. Industry guides recommend asking for verifiable operational data and doing live or third-party checks.

Dive deeper: operational checks that expose hidden problems

Operational issues are behind-the-scenes risks. I focus on three areas: real factory vs. trader, capacity realism, and personnel/process stability.

Real manufacturer vs. trading company

- Why it matters: Traders resell and may source from multiple anonymous factories. This causes inconsistent product quality, longer lead times, and poor traceability.

- How I check: Ask for utility bills, production photos with timestamps, and names of factory managers. Cross-check addresses and company registration to see if manufacturing is listed.

Capacity claims vs. reality

- Many suppliers inflate capacity. I compare claimed monthly output to visible machinery. For PVC edgeband, one line’s output has practical limits. Ask for machine models and calculate plausible output. If numbers don’t add up, that’s a warning. Guides suggest asking for live video of the lines making your specific product.

Workforce and process stability

- High worker turnover or lack of trained QC staff leads to inconsistent products. I ask about staff experience, on-site QC processes, and whether they keep standard operating procedures. If they say “we train on the job” with no SOPs, I raise the alarm.

Operational proof table

| Hidden risk | What I request | Red flag answer |

|---|---|---|

| Trading vs factory | Utility bill, production video | “We don’t have the video” |

| Fake capacity | Machine models, output logs | Vague numbers, no logs |

| No SOPs | Written SOPs, QC staff list | “We do it by feel” |

If the supplier fails these operational checks, I don’t move forward.

Financial and Compliance Red Flags That Put Your Orders at Risk?

Money and paperwork are the foundation. I lost a small deposit once. I never let finance or compliance be fuzzy again.

Watch for odd payment terms (large upfront, insist on personal accounts), missing business registration, expired or fake compliance documents, and inconsistent export experience. Market guides and sourcing experts list suspicious payment requests and unverifiable certifications as top signs of risk.

Dive deeper: payment rules, certifications, and how to protect yourself

Finance and compliance are objective checks. I use them to decide fast.

Payment red flags and safe options

- Red flags: Requests for large prepayments to unknown personal accounts, refusal to use traceable banking, or insistence on non-refundable deposits. These behaviors increase scam risk.

- My rules: Use letters of credit for large orders, or pay a small deposit (e.g., 20%) then the balance against B/L or pre-shipment inspection report. For new suppliers, I prefer escrow or third-party platforms until trust builds. Guides on Alibaba and sourcing experts echo these practices.

Certifications and compliance checks

- Common certificates to request: Product safety test reports (e.g., formaldehyde, RoHS-like tests), material composition/ingredient lists, and factory compliance reports. Always verify certs via the issuing body or request raw lab reports from recognized labs (SGS, Intertek). If a supplier claims certifications but won’t let you verify them, treat that as a major red flag.

Financial stability and tax behavior

- A supplier that delays paying raw-material vendors or has public complaints about tax issues may suddenly stop production. I ask for at least two trade references and check for business registration and tax status. If they are evasive, I avoid long-term commitments.

Simple protection checklist

| Risk | What I require | Protective action |

|---|---|---|

| Large prepayment demand | Company bank account, invoice | Escrow, L/C, or reduced deposit |

| Fake certs | Cert numbers, lab contact | Verify with cert body |

| No trade refs | Past customer contacts | Ask for references + check them |

If any of these fail, I either negotiate strict protections or walk away.

How to Vet and Confirm a Reliable PVC Edge Banding Supplier Before You Place Orders?

I now treat vetting as a checklist I follow every time. It saved me time and money.

A reliable vetting process includes document checks, sample testing, live factory verification, and a pilot order with strong QC terms. I always insist on inspection points and clear terms in the contract. Practical sourcing guides back this multi-step approach.

Dive deeper: step-by-step vetting I use (and you can copy)

Here is the sequence I follow. It’s practical and repeatable.

- Initial screen

- Check company registration, website, and product pages.

- Reverse-image search photos.

- Ask for basic production details (lines, capacity, main raw-material suppliers).

- Document and certification check

- Request TDS, peel and tensile test reports, and any third-party lab reports.

- Verify certificates with issuing bodies or ask for lab contact details.

- Samples and tests

- Ask for at least two production-batch samples.

- Run peel, tensile, and color stability tests. Compare against spec.

- If possible, test in real production conditions or on one piece of furniture.

- Factory verification

- Request live video of the actual machines making your product.

- If critical, arrange a third-party factory audit or in-person visit.

- Ask for photos showing batch numbers and date stamps.

- Pilot order and QC terms

- Start with a small paid pilot order with clear acceptance criteria.

- Include pre-shipment inspection by a named third party.

- Define penalties for out-of-spec shipments.

- Payment and contract

- Use safe payment terms: escrow, L/C for large orders, or staged payments.

- Include warranty, return, and rework clauses.

Why this works: Each step reduces uncertainty. If a supplier balks at any of these checks, that tells you something important: they can’t back up their claims.

Conclusion

I now avoid risky suppliers by using clear checks: transparency, real samples, solid QA, verified finances, and staged orders.

Data sources (I used these when writing this article)

- PVC Decorative Film — “What Questions Must You Ask PVC Edge Banding Distributors?”.

https://pvcdecorativefilm.com/pvc-edge-banding-distributors/ - EdgeBandCT — “How to Source PVC Edgeband from Reliable Chinese Manufacturers” and related guides. (Edge Band CT)

https://edgebandct.com/ - Best in Group — “Buy Edge Banding from China – Ultimate Guide” (sourcing tips and common issues). (bestingroup.com)

https://www.bestingroup.com/buy-edge-banding-from-china-ultimate-guide/ - SGS Product Certification Program Handbook (on verifying certifications and lab reports). (SGSCorp)

https://www.sgs.com/-/media/sgscorp/documents/corporate/brochures/sgs-product-certification-program-policy-handbook-en.cdn.en-US.pdf - Alibaba / Sourcing safety guides — “How to Spot Fake Suppliers” and red-flag lists. (China Company Lookup)

https://chinacompanylookup.com/china-supply-chain/how-to-spot-fake-alibaba-suppliers/

https://sourcify.com/power-tips-for-avoiding-alibaba-scams-when-sourcing-factories/