I used to trust low prices. That led to bad batches and angry customers. I learned to check the machines first.

A modern PVC edgeband factory pairs stable extrusion, precise color dosing, high-resolution printing, matched embossing, and automated inspection to produce consistent, saleable tape.

I will walk you through what I look for. I write from the buyer’s view. I show practical checks you can use when you visit a factory or review a supplier’s dossier. Stay with me. The details save time and money.

What Makes a PVC Edgeband Factory Truly Modern Today?

I once bought from a factory that used old single-screw extruders. The product varied by batch. I now demand twin-screw extruders, automatic dosing, UV curing for prints, and inline inspection. These elements cut variability and scrap.

I inspect machine specs and control brands. I want to see PLCs, frequency drives, and calibrated temperature control. I also check material handling. Modern factories keep resin dry and tracked by batch number. That reduces surprises at production start.

Key machine features I expect

- Twin-screw extruder for uniform melt and mixing.

- Automated pigment dosing for repeatable color.

- Calendering/embossing stations that are adjustable.

- UV curing for printing to lock inks quickly.

- Line-scan or area vision inspection for full-roll checks.

I also look for simple but important process controls. I ask for SOPs on start-up, color changeover, and cleaning. I want records that show how long it takes to move from one color to another and how wasted meters are handled. A modern factory documents this.

How Core Production Technologies Shape the Quality of PVC Edgebands?

I learned to treat each production step as a cause. Material, extrusion, printing, embossing, and QC all add variation. If one step is weak, the whole roll can fail.

I verify raw material certificates and MSDS. I compare resin grades and pigment types. I require color recipes and Delta E targets. Color measurement and control are central for repeatable matching. A good supplier measures Lab and uses Delta E thresholds for acceptance.

Material and extrusion

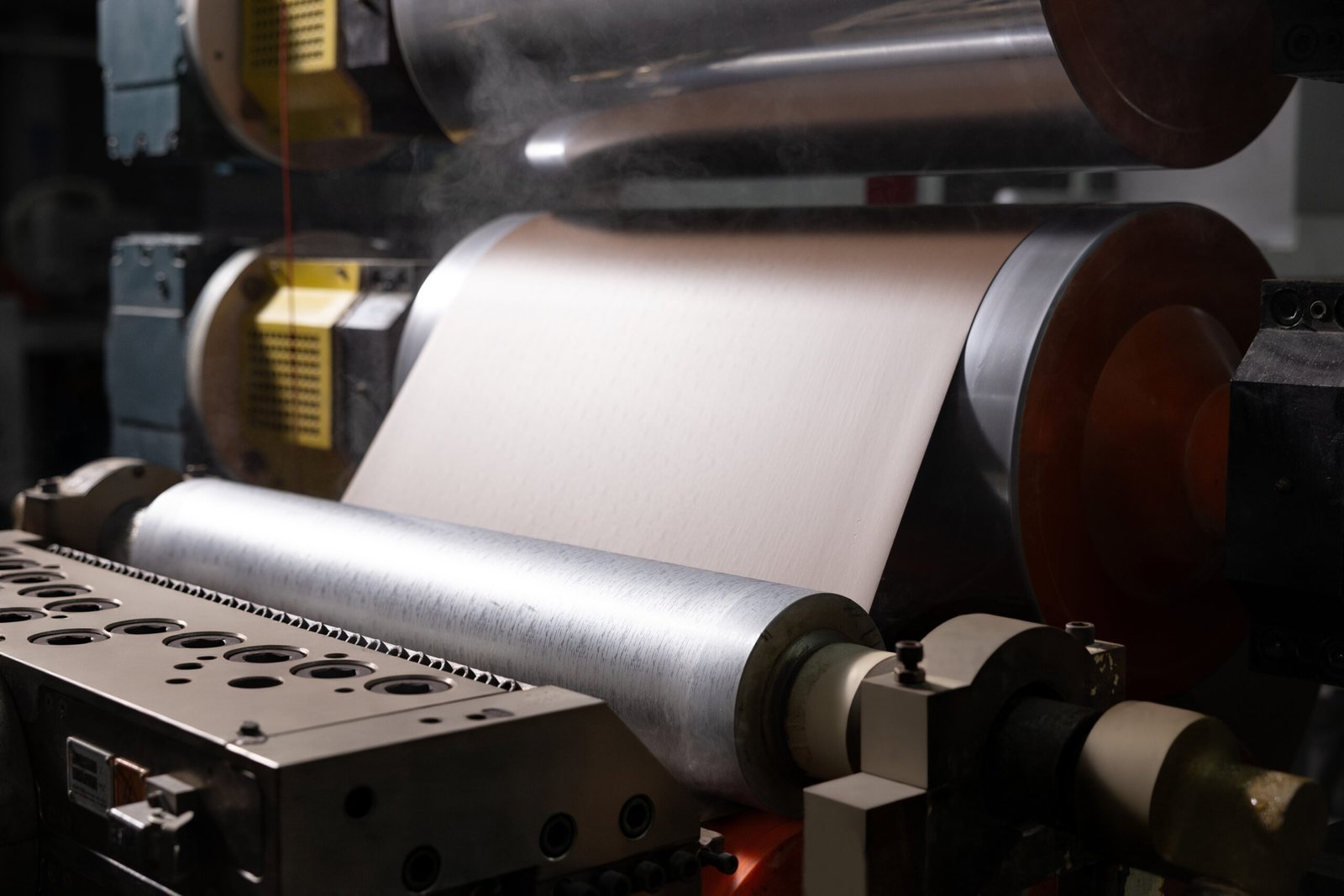

Resin quality sets the baseline. Additives and stabilizers affect melt flow and gloss. I ask for batch traceability. I also watch the extruder’s heating zones. The heating profile must be stable. A twin-screw extruder gives better mixing. That reduces unmelted pockets and pigment streaks.

Printing and embossing interaction

Printing defines the visual match. Embossing defines the tactile match. If print and embossing are out of sync, the edgeband will look wrong under light. I check registration control and embossing roller repeat accuracy. Modern rollers are laser-engraved for repeatability.

Process control and documentation

I demand SPC charts for key measures like width, thickness, and Delta E. I want data logs for production runs. A factory that logs process variables can show trends and root-cause defects faster. This lowers my supplier risk.

Why Extrusion, Printing, and Embossing Systems Define Product Consistency?

I think of extrusion as the skeleton, printing as the skin, and embossing as the feel. All three must align. If not, buyers face returns and complaints.

I test samples under multiple lights. I compare printed pattern repeat with embossing repeat. I also request print resolution specs and ink type. UV-curable inkjet systems are ideal for complex woodgrain and short runs. Gravure or roller printing is better for large, steady runs. Each method has trade-offs in cost, speed, and quality.

How I judge extrusion quality

I measure thickness along a roll. I check for bubbles or voids. I examine the edges for uniformity. An accurate calibrating/cooling table helps keep width stable. I record these results in a simple table:

| Test | Acceptable range | Why it matters |

|---|---|---|

| Width tolerance | ±0.2 mm (example) | Fit on the panel edge |

| Thickness tolerance | ±0.03 mm | Adhesion and bending |

| Delta E (DE2000) | <=2.0 (target) | Visual color match |

| Surface finish (gloss) | Specified gloss level | Match with panel sheen |

I also look at changeover procedures. The faster and cleaner the changeover, the less waste and the better for small orders. Factory case studies show that digital UV systems reduce set-up time versus traditional gravure for short, varied orders.

How Automated Quality Control Reduces Defects and Buyer Risk?

I stopped relying on manual inspection long ago. Humans miss defects and tire. Vision systems inspect every meter and log exceptions. That reduces escapes and supports traceability.

I want to see the inspection setup. A good system uses line-scan cameras to capture continuous profiles and area cameras for surface defects. Modern systems can run edge detection, contrast checks, and registration verification in real time. Some systems also use edge learning or onboard AI to reduce false positives. I check how the factory calibrates and maintains these cameras.

What automated QC finds

- Surface scratches or pinholes.

- Printing registration shifts.

- Width and thickness deviations along the roll.

- Color drift detected by integrated spectrometers or sample checks.

How I verify QC claims

I ask for recent inspection logs and corrective action records. I also request a demo run or video of the inspection in action. If a factory can deliver a quality report with timestamps and defect images, I can audit root causes and follow up on corrective steps. This gives me confidence before I scale orders.

What Buyers Should Review When Auditing a PVC Edgeband Supplier?

I bring a short checklist when I visit a supplier. I look at machines, operator skill, records, and sample traceability. I talk to engineers not only salespeople.

My on-site audit checklist

- Verify extruder type and control systems. Ask for model numbers.

- Inspect pigment dosing and color lab procedures. Ask to see Delta E targets.

- Review printing technology and UV curing setup. Ask about ink types and print resolution.

- Check embossing roller production and repeat accuracy. Ask about roller manufacturing method.

- Evaluate QC systems. Request inspection logs and demo.

- See raw material storage and batch records. Confirm MSDS and certificates.

- Ask for SOPs on changeover and cleaning. Get samples from a mixed-production day.

Pilot order and acceptance criteria

I always place a small pilot of 100–300 meters. I set acceptance limits for width, thickness, Delta E, and adhesion. The pilot must pass before I start larger runs. I include rework and replacement terms in the contract. If a factory resists these steps, I see that as a red flag.

I prefer suppliers who show data and let me verify. I choose partners who invite audits and give clear records. That protects my brand and customers.

Data sources and links:

- JWELL — PVC Edge Banding Extrusion Line (machine features and dosing systems). https://www.jwell-group.com/blog/PVC-Edge-Banding-Extrusion-Line/

- Agfa — Printing furniture edge bands with UV inkjet. https://www.agfa.com/printing/news/printing-furniture-edge-bands-uv-inkjet/ (Agfa)

- Keyence — Machine vision and inspection systems. https://www.keyence.com.sg/products/vision/vision-sys/

- Saueressig / Calender technologies — calender and embossing technical brochure (surface solutions). https://www.saueressig.com/wp-content/uploads/Image-brochure-Surface-Solutions.pdf

- Delta E measurement explainer (color tolerance importance). https://alpolic-americas.com/blog/how-is-color-measured-calculating-delta-e/ (ALPOLIC)