Finding a reliable PVC edge banding supplier is tough. Many factories claim quality, but only a few can handle large-scale production efficiently.

Choosing the right supplier for PVC edge banding ensures smooth production, consistent quality, and cost savings. This guide helps you identify the best partner for your furniture business.

Selecting a supplier is not just about price. It affects your production timelines, product quality, and customer satisfaction. Let’s explore the key factors to make the right choice.

Understanding the Key Criteria for Selecting a PVC Edge Banding Supplier?

Struggling with low-quality suppliers can cost a lot. Many promise fast delivery but fail to meet standards.

The key criteria include product quality, production capacity, certifications, and communication. Picking suppliers based on these factors ensures your furniture production runs smoothly.

Product Quality

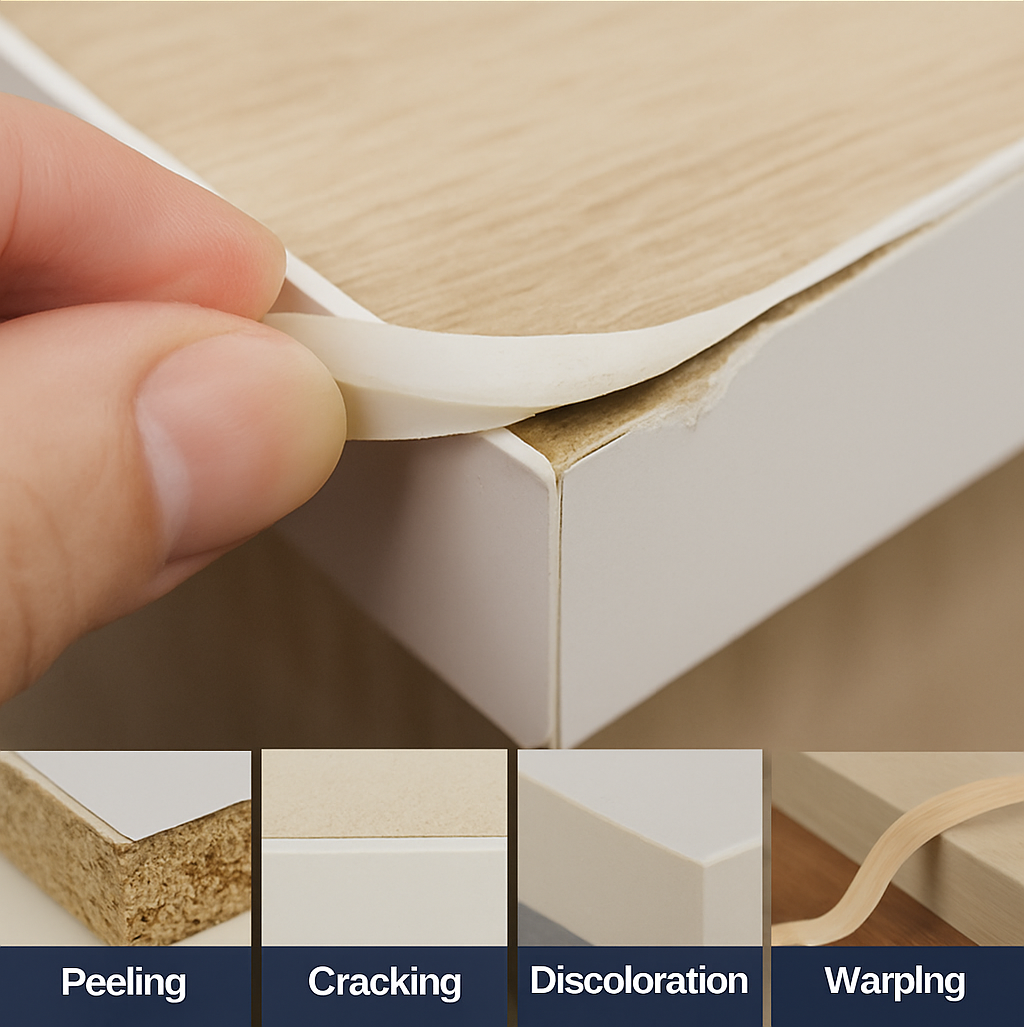

I always check if the PVC edge banding is scratch-resistant, heat-resistant, and durable. A poor-quality supplier can cause defects and customer complaints.

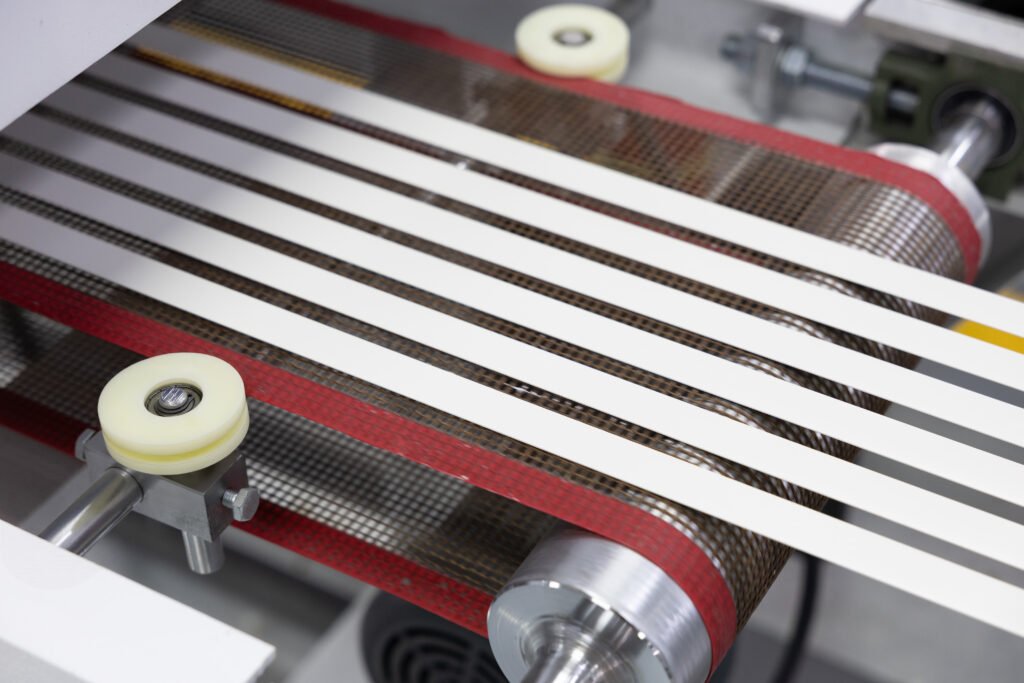

Production Capability

Suppliers should handle large orders without delays. I compare their monthly output with my production requirements. If they cannot supply consistently, it will halt my projects.

Certifications and Compliance

I look for ISO, SGS, or REACH certifications. They show the factory meets international quality standards and environmental regulations.

| Criteria | Why It Matters | How I Check |

|---|---|---|

| Quality | Prevent defects, maintain furniture durability | Request samples, test scratch and heat resistance |

| Capacity | Ensure timely delivery | Ask for monthly production volume and lead time |

| Certifications | Compliance with standards | Verify ISO, SGS, REACH certificates |

| Communication | Reduce errors, smooth coordination | Evaluate responsiveness and clarity |

Why Production Capacity Matters for Large-Scale Furniture Manufacturing?

Small suppliers look good on paper, but they fail under large orders. I have learned this from past projects.

Production capacity determines if a supplier can deliver large volumes without delays. This is crucial for meeting deadlines and maintaining client trust.

Assessing Capacity

I request detailed production schedules and compare them with my demand. For example, if I need 5 million meters yearly, a small factory producing 1 million meters will struggle.

Understanding Lead Times

Even a capable factory can face delays. I ask for their average lead time and see if they have backup machines or extra shifts to handle urgent orders.

Table: Comparing Supplier Capacity

| Supplier | Monthly Output (meters) | Max Single Order (meters) | Notes |

|---|---|---|---|

| Supplier A | 400,000 | 1,200,000 | Flexible for rush orders |

| Supplier B | 150,000 | 300,000 | Cannot scale easily |

| Supplier C | 500,000 | 1,500,000 | Strong quality control |

Evaluating Quality, Color Consistency, and Material Properties?

Inconsistent color or poor adhesion ruins furniture appearance. I learned to test every sample carefully.

Quality evaluation includes scratch resistance, heat stability, thickness uniformity, and color matching. Proper testing avoids costly errors.

Scratch and Heat Resistance

I perform simple scratch tests and heat tests. This shows if the edge banding can survive daily use and factory processing.

Thickness and Flexibility

Inconsistent thickness causes gaps or poor adhesion. I measure multiple samples and check flexibility for curved surfaces.

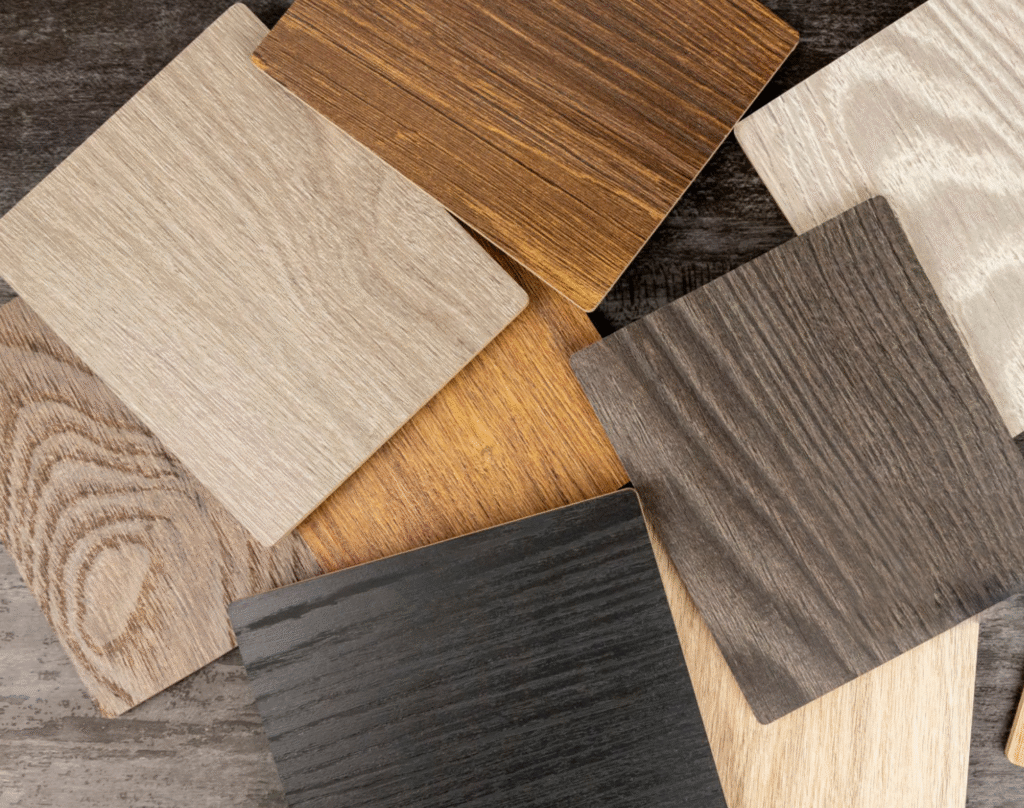

Color Matching

I compare samples with furniture panels. Suppliers with advanced color matching technology maintain consistency across batches.

| Test | Standard | My Method |

|---|---|---|

| Scratch Resistance | ≥1.5 N | Use a steel ball and measure indentation |

| Heat Stability | 80°C for 24h | Heat in oven, check deformation |

| Thickness | ±0.1 mm | Micrometer measurements at multiple points |

| Color | ΔE < 2 | Use spectrophotometer or visual comparison |

Comparing Manufacturer vs. Trading Company: Which Partner Fits Your Needs?

Trading companies promise lower prices but often hide production issues. I prefer to deal directly with manufacturers.

Manufacturers provide better control over quality, customization, and lead times. Trading companies can help with small orders or sourcing multiple products.

Advantages of Manufacturers

- Direct access to production lines

- Faster problem resolution

- Possibility to customize products

Advantages of Trading Companies

- Wide supplier network

- Handle small orders easily

- Sometimes cheaper for limited runs

Table: Manufacturer vs Trading Company

| Factor | Manufacturer | Trading Company |

|---|---|---|

| Price | Medium | Often lower upfront |

| Quality Control | High | Depends on factory |

| Lead Time | Predictable | Varies |

| Customization | Easy | Limited |

| Order Volume | Large | Small to medium |

Tips for Ensuring Reliable Delivery and Long-Term Partnership?

Even with a great supplier, delivery issues can happen. I learned that clear agreements prevent most problems.

Reliable delivery depends on contracts, clear communication, and regular monitoring. Building a long-term partnership requires trust and shared goals.

Set Clear Contracts

I include lead times, quality standards, and penalty clauses in contracts. This protects both sides.

Regular Communication

I schedule weekly updates and share production forecasts. It avoids misunderstandings and prepares for rush orders.

Monitor Performance

I track on-time delivery rates, defect rates, and responsiveness. Consistent performance indicates a reliable partner.

| Tip | Reason | My Practice |

|---|---|---|

| Contract | Ensure expectations | Written terms with clear KPIs |

| Communication | Prevent errors | Weekly calls and updates |

| Monitoring | Maintain quality | Track defect rates and delivery times |

| Sample Testing | Avoid surprises | Test every new batch |

Conclusion

Choosing the right PVC edge banding supplier ensures smooth production, consistent quality, and long-term business growth.

Data Sources:

- International Furniture Manufacturing Association: https://www.ifma.org

- SGS Testing Standards: https://www.sgs.com

- PVC Edge Banding Industry Report 2024: https://www.pvcedgebandingreport.com