I used to lose sleep over returns and failed factory audits. Certification fixed that problem fast.

Certified factories give predictable quality, legal compliance, and lower supply risk for big furniture brands. They prove this with standards, lab data, and traceable records.

I will show why brands choose certified suppliers. I will list the key certifications. I will explain what each one means for quality, safety, and supply. Keep reading if you want fewer surprises from your supplier.

What “Certification” Really Means in PVC Edge Banding Manufacturing?

I once thought a certificate was just a sticker. I was wrong.

Certification is an audited proof. It shows the factory follows repeatable systems. It covers quality management, environmental controls, and chemical compliance. For PVC edge banding, the most relevant certificates are ISO 9001 (quality), ISO 14001 (environment), REACH and RoHS (chemical rules), and CARB/TSCA or equivalent for formaldehyde and emissions. Brands also ask for test reports from accredited labs. A certificate alone is not enough. I want the records behind it. Proofs like batch records, COAs, and lab curves matter more to me than a logo on a brochure.

Dive deeper — types of certification and what they prove

I break certification into three groups: management systems, chemical and product compliance, and test/report evidence.

Management system certifications. ISO 9001 shows the company has documented processes for design, production, and corrective action. ISO 14001 shows the company manages environmental risk. I value these because they mean processes are repeatable. When a problem happens, the factory has a method to find and fix the root cause. I ask for the latest audit date and the scope of the certificate.

Chemical and product compliance. REACH covers hazardous substances in the EU. It limits substances of very high concern. New REACH rules added limits on lead in PVC; this matters for edge banding. RoHS often applies if products go near electronics, but many buyers still ask for RoHS checks as a precaution. CARB (California) and the U.S. Formaldehyde Standards require low-emission composite wood products. Even though edge banding is not the composite board itself, brands that sell in regulated markets want suppliers who understand and can document that their edge banding will not cause the final assembly to fail compliance tests.

Test and lab evidence. I ask for third-party lab test reports for ΔE color, gloss stability, accelerated UV, and migration tests for plasticizers and stabilizers. I also want SDS (safety data sheets) and COAs for raw materials. These documents let me verify claims.

Why brands care. Brands operate in strict retail and legal environments. A certificate signals controls. The documents behind the certificate prove them. I always insist on both.

How Certified Factories Guarantee Stable Quality and Color Consistency for Large Orders?

A sample that looks right is not enough. Big orders show variation fast.

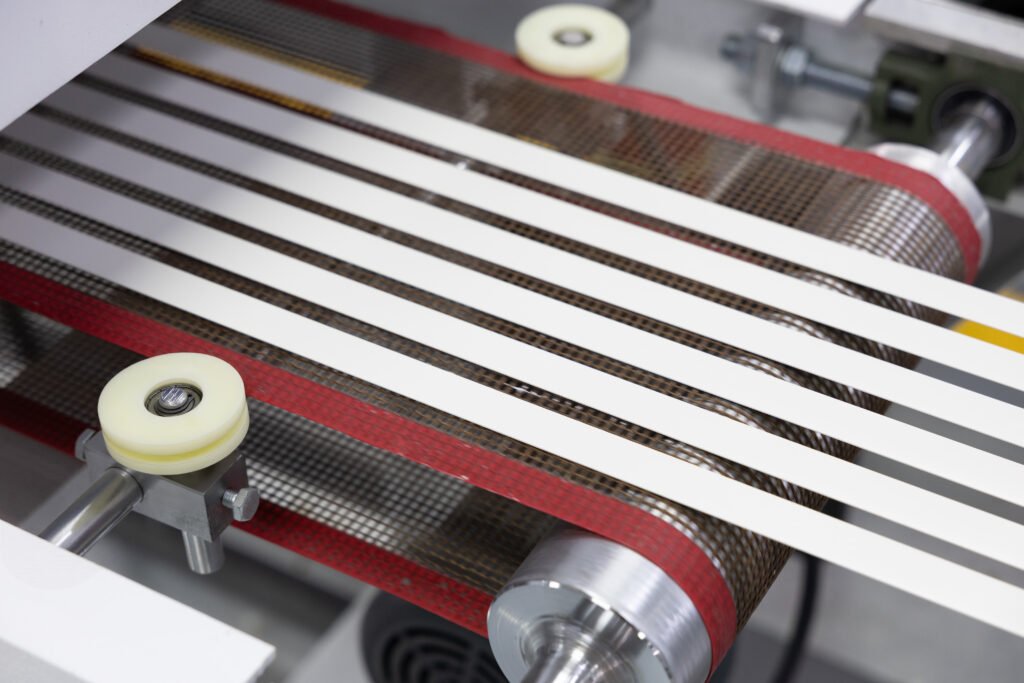

Certified factories set up process control and measurement. They use instruments and logs. They record machine setpoints, color files, and gloss numbers. They run SPC (statistical process control) on key metrics. They keep sample archives and batch traceability. That reduces surprises when you scale from a sample roll to thousands of meters.

Dive deeper — the systems I expect and the tests they run

I check four technical pillars: instrument-based color control, process SOPs, sample retention, and corrective systems.

Instrument-based color control. I require spectrophotometer readings in CIELAB and ΔE2000 reports. I ask suppliers to measure under D65 lighting and to log geometry (45/0 or sphere). I set tolerance bands in the PO. For high-end furniture I push for ΔE ≤1.5. For utility projects I accept ΔE ≤3. These numeric targets remove debate during acceptance inspections.

Process SOPs and SPC. Certified factories document the recipe, extrusion temperature profile, cooling rate, printing register, and coating cure profiles. They run SPC charts on thickness, ΔE, and gloss units (GU). When a KPI drifts, their system triggers escalation. I ask to see example SPC charts or change logs to confirm the system works.

Sample retention and traceability. I want a retained sample and measurement file per batch. That allows re-tests months later. I also want raw-material lot numbers linked to finished-batch IDs. If an issue appears in the field, tracing back stops more bad product from shipping.

Corrective action and continuous improvement. ISO 9001 requires corrective action systems. I ask for a recent nonconformance report and how the factory fixed it. A good supplier shows how they prevented recurrence.

I learned to treat data as the contract. Certified factories usually deliver such data. That is why brands prefer them.

Why Compliance, Safety Standards, and Material Testing Matter for Global Furniture Brands?

A failed compliance test can stop a product launch. That risk is costly.

Global brands sell in many markets. Each market has rules. The EU enforces REACH and chemical limits. The U.S. enforces formaldehyde rules (CARB/TSCA). Retail chains and large OEMs require certificates and COAs. Brands avoid suppliers who cannot supply these documents fast. They need proof that the finished furniture will meet the retailer’s test plan. This lowers recall risk and legal exposure.

Dive deeper — key regulations and the tests I require

I focus on four compliance areas: REACH substance limits, formaldehyde emissions context, RoHS where applicable, and documented lab testing.

REACH and restricted substances. REACH controls substances like lead and certain plasticizers. In 2023 the EU tightened rules on lead in PVC, with compliance deadlines in 2024. I require REACH declarations and, when needed, third-party tests for restricted elements. This avoids shipments being stopped in the EU.

Formaldehyde emissions and CARB/TSCA context. CARB and U.S. formaldehyde rules apply to composite wood panels. Though edge banding is not the board, the finished product must meet emission limits. Brands that sell in North America want suppliers that can prove their edge banding will not raise emission levels beyond limits. I request SOPs showing that adhesives and top-coats do not increase emissions.

RoHS and niche cases. If the furniture includes electronics or is adjacent to electronic equipment, RoHS checks become relevant. Some brands ask for RoHS-style lab tests for peace of mind even if strictly not required.

Lab testing I require. ΔE color reports, gloss stability, accelerated UV aging, plasticizer migration, and heavy metal screen tests form my core lab checklist. I prefer accredited labs (ISO/IEC 17025) for critical tests.

Compliance is not marketing. It protects the brand and the supply chain. That is why brands pay for certified partners.

How Certified Factories Reduce Supply Chain Risk and Improve Long-Term Reliability?

Risk is not just about product. It is about schedule, cost, and reputation.

Certified factories have documented sourcing, ERP controls, and supplier qualification systems. They keep safety stock for critical compounds. They run supplier audits for masterbatch and resin makers. They plan capacity and maintain redundancy. These habits reduce lead-time surprises and raw-material quality shocks.

Dive deeper — concrete practices that cut risk

I verify risk control in four areas: raw-material contracts, inventory policy, equipment redundancy, and audit trails.

Raw-material contracts and supplier qualification. Certified factories often contract with stable resin and masterbatch suppliers. They collect SDS and COAs for each lot. I ask for supplier lists and recent qualification audits. Stable sourcing reduces sudden formula changes.

Inventory and safety stock. Factories that serve global brands keep buffer stock for resin, stabilizer packages, and masterbatch. They plan purchases by lead time and seasonal trends. I ask for their reorder point, lead-time data, or ERP screenshots. This shows whether they will run out at a critical time.

Equipment redundancy and maintenance. I prefer factories with more than one line for priority SKUs. I also want preventive maintenance logs. When a key extruder breaks, a second line or fast spare parts avoid shipment delays.

Audit trails and reporting. Certified factories keep electronic records. They can produce batch reports, QC logs, and shipment photos quickly. That transparency reduces the time to resolve disputes.

These systems translate to fewer late shipments, fewer surprise costs, and fewer recalls. For a furniture brand, that means steady store shelves and steady revenue.

Why OEM, Private Label, and International Retail Chains Require Certified Suppliers?

Large buyers have rules. They expect proof.

OEMs and retailers often require certificates in their supplier terms. They run audits. They demand COAs and test reports. They require corrective action plans. They also require insurance and liability limits. Certified factories fit these needs. They make the buying process faster and safer.

Dive deeper — procurement rules and the practical impact

I have negotiated contracts with big retailers. Their procurement teams run standard checklists. These include ISO 9001, REACH declarations, COAs, and sometimes social compliance audits (like BSCI). If a supplier cannot provide these items, the buyer will not approve them.

Procurement clauses I see often. Proof of ISO 9001 or equivalent. Material safety data sheets for all shipped products. Third-party lab test reports for chemical limits. Packaging and palletizing specs. Traceability from raw-material lot to finished-roll ID. A supplier that meets these items can be fast-tracked.

Why this matters commercially. Brands need predictable launches and consistent quality at scale. A certified supplier shortens the approval cycle. It reduces the need for repeated lab testing. It reduces the chance of a shipment-held-at-customs scenario. It also reduces the legal exposure if a product fails later.

How I use this in sourcing. I include certification and document delivery timelines in the RFQ. I require initial document submission before sample approval. This approach speeds approvals and protects timelines.

Certified suppliers remove roadblocks. That is why major buyers insist on them.

I pick partners who show systems, not just slick brochures. Certification is proof of systems. Data beats promises.

Dive deeper — my practical supplier checklist

I use a short, practical checklist when I vet suppliers:

- Ask for ISO 9001 certificate and audit scope.

- Request REACH and RoHS declarations.

- Ask for SDS and COA for resin and masterbatch.

- Require recent ΔE and gloss reports from an accredited lab.

- Request sample retention and batch traceability practice.

- Ask for packing photos and export docs sample.

- Insist on a documented corrective action example.

I use the checklist in the RFQ. I only proceed to sample approval after documents arrive. This method saved me from two costly recalls and many late shipments.

Conclusion

Brands prefer certified PVC edge banding factories because they lower product, legal, and schedule risk. Trust data, not words.

Data sources and links

- Composite Wood Products Airborne Toxic Control Measure (CARB). https://ww2.arb.ca.gov/our-work/programs/composite-wood-products-program.

- U.S. Formaldehyde Standards for Composite Wood Products https://www.ecfr.gov/current/title-40/chapter-I/subchapter-R/part-770.

- EU REACH regulation changes (lead in PVC). Intertek analysis. https://www.intertek.com/products-retail/insight-bulletins/2023/eu-adds-requirements-for-lead-in-pvc-under-reach-regulation/. (Intertek)

- ISO 9001 importance for manufacturers. https://frem.co.uk/about-us/news/why-iso-certifications-matter-for-furniture-manufacturers. (frem.co.uk)

- Datacolor — Delta E best practices. https://www.datacolor.com/business-solutions/blog/best-practices-delta-e-tolerances/. (Richelieu Hardware)

- Example SDS for PVC edgeband (manufacturer). https://www.surteco.com/fileadmin/surteco.com/services/downloads/sicherheitsdatenblaetter_kante/SUR_Sicherheitsdatenblatt_PVC_Edgeband_EN_L01.pdf. (surteco.com)