I see the gaps you face when edges fail to match or deliveries slip. I once lost a run to a mismatch. I learned fast how suppliers matter.

Suppliers keep your panels finished, matched, and ready. Good partners control color, stock, speed, and inspection. They cut rework and save time and cost.

I will walk you through the practical steps. I explain what to check. I share actions you can take with your supplier. Read on to avoid common mistakes and speed up production.

Why Reliable Edge Banding Supply Matters for Panel Furniture Brands?

I once had an urgent order delayed because the edgeband supplier ran out of stock. The client waited. I lost trust. I fixed this by finding a steady supplier.

Reliable supply keeps lines moving. It avoids stoppages. It keeps lead times stable. It protects margins and client trust.

Dive deeper: How supply reliability affects operations and what to demand from suppliers

I view reliable supply as the backbone of production. When edgeband arrives on time, my schedule stays stable. When it does not, I scramble. Delays force overtime. They raise cost. They break customer trust.

I break the problem into three parts:

1) Inventory and capacity planning

Suppliers must hold stock for common colors and sizes. They must plan runs for custom colors. I ask suppliers for their safety stock levels. I ask how fast they can ramp production for larger orders.

2) Lead time transparency

I want clear lead times for regular items and for custom colors. I set reorder points that match supplier lead times. I use a simple rule: reorder when stock equals two weeks of production. This reduces emergency orders.

3) Risk and backup

I expect suppliers to have backup plans. That can mean a second production line or local warehousing. I also keep a small, trusted secondary supplier for very urgent needs.

| Risk area | What I expect from supplier | What I do |

|---|---|---|

| Stockouts | Publish safety stock levels | Reorder at two-week supply |

| Lead time changes | Notify immediately | Shift production plan quickly |

| Large rush orders | Ramp capacity or split runs | Use secondary supplier |

Reliable suppliers often belong to larger supply networks. They invest in inventory and planning. This is why market size and supplier scale matter. A growing global market means bigger suppliers can offer more stock and options.

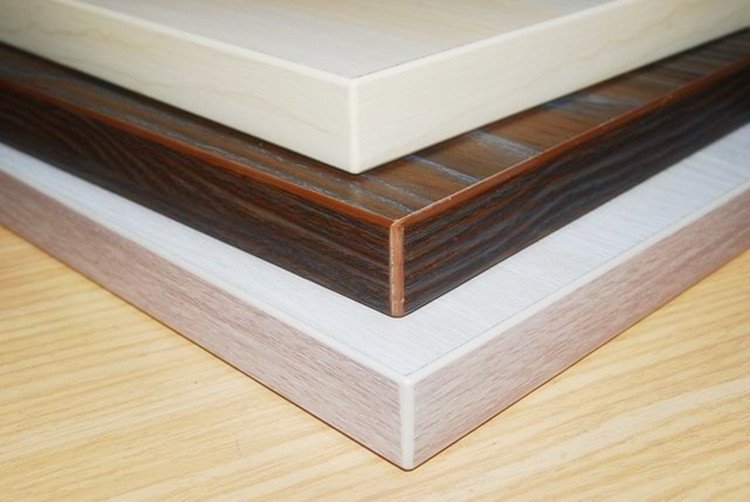

How Edge Banding Suppliers Ensure Accurate Color and Texture Matching?

A poor color match looks cheap. I lost a demo because the edge did not match the panel. I now test color matches before big runs.

Suppliers use spectrophotometers, ΔE targets, and sample rolls to match colors. Good matching cuts rework and returns.

Dive deeper: Color science, testing methods, and how to set acceptance criteria

Color and texture matching is both science and craft. I treat it as non-negotiable for brand work. Small ΔE differences show under showroom light. Customers notice. So I demand measurable proof.

Basic tools and terms

- Spectrophotometer: gives numeric color values.

- ΔE: the difference between two color values. Lower is better.

- Texture/emboss: surface finish that affects look under light.

How I run tests

I start with a physical sample. Then I ask the supplier for a lab reading. I set a ΔE threshold. For most furniture I accept ΔE ≤ 2. For high-end lines I ask for ΔE ≤ 1. These are practical goals that cut visible mismatch.

Matching workflow with supplier

- Send the panel sample to supplier.

- Supplier produces a trial roll.

- Supplier measures ΔE and shares the report.

- I approve or request tweaks.

| Step | Supplier deliverable | My acceptance check |

|---|---|---|

| Sample trial | Trial roll + ΔE report | Visual check + ΔE ≤ target |

| Small pilot | 20–50 m roll | Check under real light |

| Full run | Batch reports + QC photos | Random quality checks |

Suppliers that invest in color labs and stable printing processes give me confidence. They also document results so I can prove matches to clients. Automation and software help with consistency and speed. This reduces subjective claims and saves production time.

Production Capabilities That Help Manufacturers Scale Faster?

I once scaled a client from local stores to national supply. The right supplier handled the volume. They kept color and quality stable. That made growth painless.

Suppliers with high extrusion capacity, varied widths, and quick custom tooling help me meet scale. They lower unit cost and reduce lead times.

Dive deeper: What production capabilities matter and how to evaluate them

When I plan growth, I weigh supplier capabilities heavily. I look for machines, formats, and flexibility.

Key production capabilities

- Extrusion capacity: determines max output.

- Multiple widths and thicknesses: helps match many product types.

- Printing and coating lines: needed for patterns and protective finishes.

- Pre-gluing and different backers: saves glue time at my plant.

How I evaluate suppliers

I visit the factory or ask for a virtual tour. I check production schedules and machine specs. I ask about batch size limits. I check sample lead times for custom colors. I also ask whether the supplier can run small batches that match full-run specs. Suppliers that can do both small pilots and large runs reduce risk.

Costs and scale

Higher capacity often lowers unit costs. But capacity alone is not enough. I want steady quality at scale. A supplier with many lines can handle growth without sudden delays.

| Capability | Why it matters | What I check |

|---|---|---|

| Extrusion lines | Volume and redundancy | Number of lines and uptime |

| Print reliability | Color and pattern quality | Sample consistency reports |

| Pre-glued option | Faster assembly | Adhesive quality and shelf life |

| Small-batch runs | Flexibility for samples | Minimum run size |

Market reports show the edge banding market is expanding. This growth means more suppliers now invest in capacity. That trend helps me negotiate better terms and secure stock for growth.

Quality Control Systems That Reduce Defects in Panel Furniture?

I used to accept visual checks only. Then a client returned a batch with peeling edges. I added stricter QC steps with my supplier. Returns dropped fast.

Good suppliers use testing for adhesion, UV resistance, and dimensional tolerance. They follow standards and report results. This saves me rework and warranty costs.

Dive deeper: Tests, standards, and workflows that protect final product quality

I treat QC as a shared task. Suppliers must test. I also do random checks on arrival.

Core tests suppliers should run

- Peel/adhesion test: measures bond strength. This affects durability.

- UV/fade test: checks color stability under light.

- Dimensional tolerance: checks width and thickness within spec.

- Impact and flexibility tests: ensure edges resist knocks and bending.

Standards and laboratory work

I ask for test reports aligned with recognized methods. Tests like peel strength and weathering are common. I also reference academic work that shows how process variables affect bond strength. This helps me set realistic acceptance levels.

My arrival inspection list

- Visual check under normal and bright light.

- Measure width and thickness on random rolls.

- Peel test on a sample joint.

- Record supplier batch number and keep for traceability.

| Test type | Why it matters | Action I take |

|---|---|---|

| Peel strength | Edge won’t peel in use | Reject if below threshold |

| UV resistance | Color stays true | Check supplier report |

| Dimensional | Fits machinery and design | Return if out of tolerance |

| Flex/impact | Withstands handling | Use rated edges for high-stress parts |

I prefer suppliers that follow QC systems and give batch reports. That makes root-cause work easier if problems happen. It also reduces my warranty claims and saves money.

Value-Added Services Suppliers Provide to Boost Manufacturers’ Efficiency?

A supplier that only ships rolls is fine. But one that offers pre-glued tape, custom reels, JIT delivery, and co-packaging changes everything. I save hours on assembly and shipping.

These services reduce steps on my line. They let me focus on final assembly and delivery. They improve time to market.

Dive deeper: Common value-added services and how to leverage them

I value suppliers that go beyond the roll. They offer services that cut my touch time.

Typical value-added services

- Pre-glued edge banding: eliminates glue station setup.

- Custom reel sizes: reduce waste and handling.

- Just-in-time delivery (JIT): aligns supply with my line.

- Kitting and co-packaging: send parts already paired with panels.

- Technical support: onsite setup help and training.

How I use these services

Pre-glued tape means one less machine and operator. JIT reduces warehouse needs. Kitting speeds assembly. I negotiate these into contracts for steady runs. For prototypes, I ask the supplier to pre-match and send labeled kits.

| Service | Benefit to me | When I use it |

|---|---|---|

| Pre-glued | Save glue time | High-volume runs |

| Custom reels | Less waste | Specific machine needs |

| JIT | Lower inventory | Tight warehouse space |

| Kitting | Faster assembly | Complex orders |

Suppliers that offer technical help shorten my learning curve. They also reduce setup mistakes. I prefer partners that document processes and offer training. That helps when I scale to new product lines. Technical data sheets from major suppliers also guide my choices on material and processing.

Conclusion

I rely on partner suppliers for steady stock, precise color, scalable output, strict QC, and time-saving services.

Data sources and links:

- IMARC Group — Edge Banding Materials Market Size, 2024. https://www.imarcgroup.com/edge-banding-materials-market. (IMARC Group)

- PVC Decorative Film — Color Consistency in PVC Edge Banding. https://pvcdecorativefilm.com/boost-pvc-edge-banding-quality-with-color-consistency/. (pvcdecorativefilm.com)

- North Carolina State University / BioResources — Optimization of Edge-Banding Process Parameters. https://bioresources.cnr.ncsu.edu/resources/optimization-of-edge-banding-process-parameters-used-for-particle-board-and-medium-density-fiberboard/. (BioResources)

- REHAU — Edge Band Technical Data Sheet. https://www.rehau.com/downloads/886866/edgeband-technical-data-sheet.pdf. (REHAU)

- ELECO / Automation paper — Automated Chipboard to Edge Band Matching. https://www.eleco.org.tr/ELECO2025/Eleco2025-Papers/6.pdf. (eleco.org.tr)