Struggling to find a reliable PVC edge banding supplier? You’re not alone. Many distributors face poor quality and delivery failures that delay production lines.

Choosing the right supplier can save time, cut costs, and keep your clients happy. The key is knowing what to compare beyond price.

Understanding how to compare suppliers helps you avoid hidden risks and build a dependable supply chain. Let’s dive into the real criteria that matter.

What Really Matters When Comparing PVC Edge Banding Suppliers as a Distributor?

Every distributor wants low prices. But cheap edge banding often hides quality issues like color mismatch and uneven thickness that disrupt production and cost more later.

When comparing suppliers, the biggest value comes from consistency, reliability, transparency, and service. Price is important. But real success comes from predictable quality and stable supply that supports your production goals.

Key Factors to Compare

Quality Standards Matter

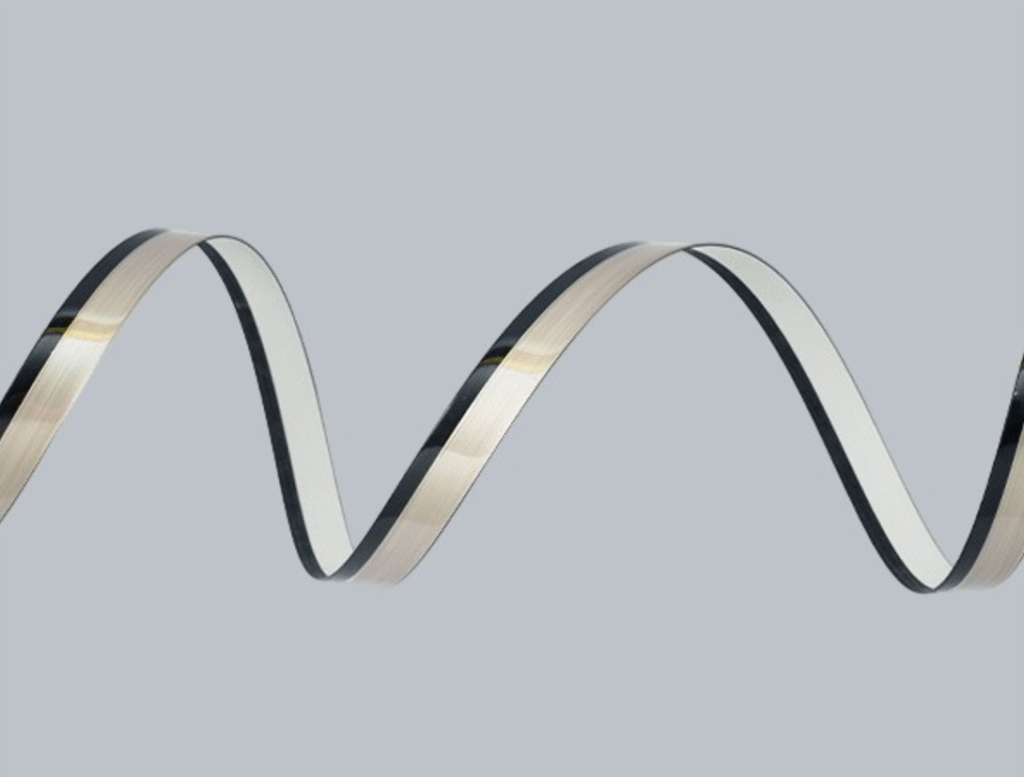

Quality is not just about look—it’s about performance and consistency. Top distributors will share technical data on raw materials, thickness tolerance, and color standards.

| Factor | Why It Matters |

|---|---|

| PVC raw material grade | Determines durability and flexibility |

| Thickness & width tolerance | Ensures smooth trimming & assembly |

| Color matching standard | Prevents visible mismatches in final product |

| Performance data (UV, scratch, flexibility) | Shows how product holds up over time |

Look for suppliers who can explain their quality control process and share sample QC reports. A supplier that hesitates or is vague likely lacks consistent control.

Transparency and Communication

Real manufacturers provide clear answers and documentation. They should readily share:

- Technical specs/TDS

- Machine capacity & process details

- Lead times and batch tracking

Vague answers often signal weak processes.

Flexibility & Custom Options

Your clients may need unique colors, textures, or sizes. A strong supplier offers customization with clear steps and timelines. High inflexibility limits your competitiveness and product range.

How to Evaluate a PVC Edge Banding Manufacturer’s Product Consistency and Color Matching Ability?

Color mismatches and inconsistent thickness ruin furniture aesthetics and assembly. I learned this the hard way when a large order returned due to slight shade differences.

A supplier who can’t guarantee color and spec consistency will disrupt production schedules and damage your reputation.

What to Ask About Consistency

Raw Material and Process Controls

- What PVC resin grade do you use?

- Do you use spectrophotometers for color measurement?

- What tolerance do you commit to (e.g., Delta E <1)?

These answers reveal whether the supplier truly controls production or just guesses.

Batch Tracking and QC Reports

Ask for batch codes, production dates, and inspection logs. This helps you track quality over time and match new shipments to older ones.

Why This Matters

A slight color shift on a large project shows immediately. Consistent product avoids:

- Rework & delays

- Client complaints

- Waste from rejected parts

Many top suppliers provide strict color controls and documented tolerances. Your job is to confirm these claims with data and samples.

Quick Consistency Checklist

- Sample from current production (not just a brochure)

- Color match test under controlled lighting

- Thickness measured with calibrated tools

A supplier who can’t support these simple checks isn’t prepared for long-term business.

How to Verify a Supplier’s Production Capacity and Delivery Reliability?

Late deliveries disrupt production. I once lost a week of woodshop time because a supplier missed a delivery. It cost more than the product price itself.

Production Capacity

Ask for:

- Monthly output in meters or rolls

- Number of extrusion lines

- Typical uptime & maintenance schedules

Capacity claims must match reality. If a supplier claims huge output but shows old equipment or no records, that’s a red flag.

Delivery Records

Request historical on-time delivery rates (e.g., percentages for the last year). Reliable suppliers will track this. A rate of 95% or higher is strong.

Warehouse & Lead Times

Determine:

- Warehouse locations

- Standard lead times for stock vs custom products

Good suppliers offer clearly defined lead times and sometimes regional hubs to speed delivery.

Incoterms and Logistics Support

Experienced suppliers know Incoterms (FOB, CIF, DDP). Those who can manage customs and door-to-door shipping add value.

What Pricing Structures Reveal About a PVC Edge Banding Supplier’s Real Business Model?

Low prices sound good. But if price is the only selling point, that often means corners are cut. Many suppliers compete on price alone, hiding quality issues or unstable supply.

Breaking Down Pricing

| Pricing Element | What It Tells You |

|---|---|

| Very low base price | Possible quality shortcuts |

| No MOQ shown | Might be trading company, not manufacturer |

| High custom prices | Reflects real production costs |

Real manufacturers balance price with quality, consistency, and service. If a supplier refuses to show production costs or MOQs, that’s a warning sign.

Understand True Costs

Beyond meter price, consider:

- Freight & logistics

- Sampling & pilot runs

- Quality control costs

These affect your margins and delivery performance.

Pricing Transparency

Suppliers who share pricing logic show professionalism. Vague or evasive pricing often hides risk and future conflicts. Let price be part of a bigger story—value, not just digits.

How to Identify Long-Term PVC Edge Banding Partners vs Short-Term Trading Factories?

A partner supports growth. A short-term factory sells once and vanishes. Many distributors mistake a trading company for a manufacturer and regret it later.

Direct Manufacturer vs Trading Company

Direct manufacturers have:

- In-house technical teams

- Real production data

- Stable QC processes

Trading companies often:

- Source from multiple factories

- Provide inconsistent quality

- Lack transparency

Ask for:

- Factory tours or live video

- Utility bills or production photos

- Production process SOPs

If they dodge these, they’re likely not the real maker.

Support and After-Sales

A real partner offers:

- Technical support for glue and machine settings

- Compliance certificates (REACH, RoHS)

- Clear claims resolution processes

A short-term supplier offers only order taking. To me, that distinction defines long-term success.

Conclusion

Comparing PVC edge banding suppliers takes data, questions, and persistence. Focus on quality, consistency, capacity, transparent pricing, and true partnership. Quality supply builds stability, reduces risk, and drives growth.

Data Sources:

– “What Questions Must You Ask PVC Edge Banding Distributors?” pvcdecorativefilm.com guide. PVC edge banding supplier questions guide

– “10 Red Flags That Reveal an Unreliable PVC Edge Banding Supplier” analysis. Supplier red flags and checks guide

– Formica technical guidelines on PVC edgebanding specs. Formica PVC edgebanding technical guide