Need your furniture to stand out from the competition? Start by fixing the edges — literally. Custom color edge banding can make or break your final product.

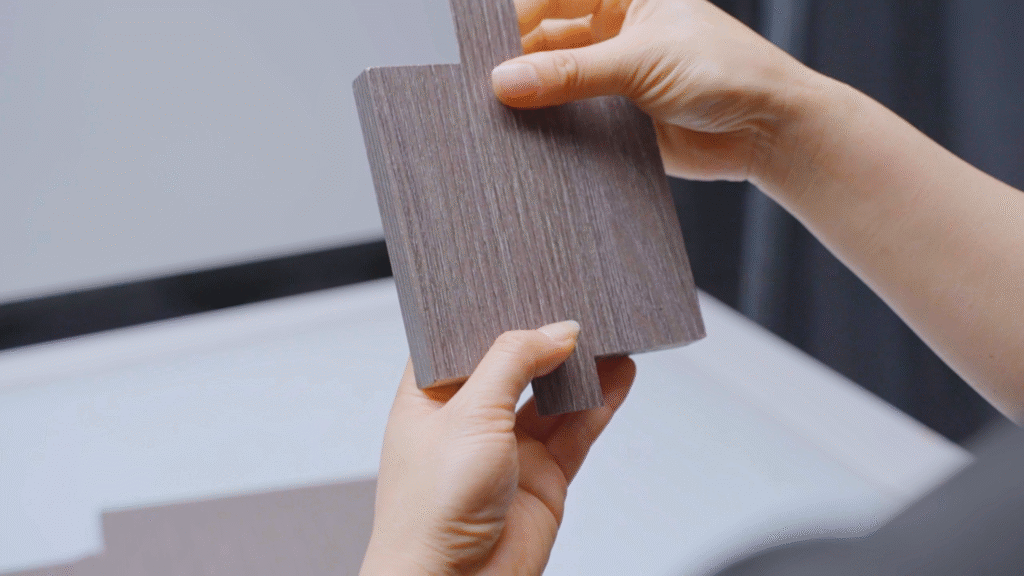

Custom color edge banding is a tailored edge finish for furniture boards, designed to match specific colors like RAL codes, Pantone shades, or branded board designs. It creates a seamless and professional look.

Generic options won’t cut it anymore. Whether you’re a furniture factory or a board distributor, the demand for color precision is rising. Let’s break down what custom color edge banding really is, how to get it right in bulk, and what to look for in a wholesale supplier.

What Is Custom Color Edge Banding and Why Does It Matter for Furniture Manufacturers?

Tired of mismatched furniture edges that scream “cheap”? You’re not alone — and there’s a fix.

Custom color edge banding is a color-matched plastic or resin strip that finishes the edges of furniture boards, creating a clean and uniform appearance across the entire surface.

Why Manufacturers Can’t Ignore This Anymore

Matching the edge with the board is not just about looks — it’s also about branding, customer satisfaction, and reducing complaints. Here’s what custom edge banding brings to the table:

1. Visual Consistency

When customers see perfect color continuity on a cabinet or panel, it instantly looks more premium. The edge doesn’t distract or look “stuck on.” It feels part of the board.

2. Professional Finish

Retailers and end users equate a clean finish with better quality. Poorly matched or generic edges can ruin even the best panel surface.

3. Product Differentiation

In crowded markets, color-matched furniture helps you stand out. You’re not selling a commodity — you’re offering a custom piece.

4. Fewer Returns and Complaints

In my experience, color mismatch is one of the top reasons buyers complain. Custom-matching the edge banding reduces this drastically.

| Feature | Generic Edge Banding | Custom Color Edge Banding |

| Visual Match | Low | High |

| Customer Satisfaction | Medium | High |

| MOQ Flexibility | High | Medium |

| Lead Time | Short | Longer |

| Price Per Roll | Lower | Higher |

Common Color Matching Standards for Edge Banding (e.g., RAL, Pantone, Board Codes)?

Ever sent a sample and still got the wrong color? That usually means the factory didn’t use the same color standard.

Common color matching standards help both factories and buyers speak the same visual language. These include RAL, Pantone, and major board brand color codes.

Making Color Matching Less Painful

Using defined standards saves you from back-and-forth color corrections. Here’s how each one works:

RAL Colors

These are widely used in Europe. They are predefined codes like RAL 9003 (signal white) or RAL 7016 (anthracite grey). If your board supplier gives a RAL code, we can match it exactly.

Pantone Matching

Mostly used in branding or North American markets. Pantone books have thousands of color options. If your design team picks a Pantone code, we can translate that into edge banding.

Board Brand Codes

Big players like Egger, Kronospan, or Wilsonart all have their own color codes. If you’re using their boards, we match the edge banding to their product lines.

| Matching Standard | Usage Area | Common Application |

| RAL | Europe | Furniture panels, paints |

| Pantone | Global | Branding, graphics |

| Board Codes | Industry-wide | Egger, Kronospan, etc. |

Color matching still needs confirmation samples. We usually send test strips before mass production. Better safe than sorry.

How to Order Custom Color Edge Banding in Bulk: Step-by-Step Guide?

Feeling overwhelmed about custom orders? Here’s how to make sure it goes smooth — every time.

Ordering custom color edge banding in bulk involves defining your requirements, confirming the color match, and coordinating MOQ, pricing, and lead time.

Step-by-Step Process

1. Define the Board Color

Give us the color reference — RAL, Pantone, or board brand code. If you only have a sample, we can scan and match it.

2. Decide on Specifications

Specify:

Width (e.g., 22mm, 28mm)

Thickness (e.g., 0.4mm, 0.8mm, 2mm)

Material (PVC, ABS, PP)

Gloss level (Matt, High Gloss, Super Matt)

3. Receive Color Sample for Approval

We produce a sample roll or strip and send it to you for confirmation. Don’t skip this — screens lie, eyes don’t.

4. Confirm Order and MOQ

Most custom colors start with a minimum of 1000m or 3000m per color. We’ll confirm details before production.

5. Production and Delivery

Once confirmed, we schedule production (normally 7–15 days depending on material and load). Shipping depends on your region and method.

| Step | Action Item | Your Role |

| 1 | Provide color reference | Mandatory |

| 2 | Confirm specs | Mandatory |

| 3 | Approve color sample | Highly recommended |

| 4 | Finalize order & MOQ | Required |

| 5 | Wait for delivery (with tracking) | Just relax |

Key Factors to Consider When Choosing a Custom Color Edge Banding Supplier?

Not all suppliers are created equal. One mistake in color or thickness can delay your whole production line.

Choosing the right custom edge banding supplier means checking their color accuracy, MOQ flexibility, material quality, and communication speed.

What I Look For (and You Should Too)

1. Color Accuracy

Ask for real samples. If they rely only on digital files, that’s a red flag.

2. MOQ Flexibility

Some factories won’t start without huge minimums. Look for ones that offer trial runs or small batch customization.

3. Lead Time Transparency

If a supplier promises everything in “7 days” without knowing your requirements, be cautious. Realistic timelines are better than broken promises.

4. Material Options

The right supplier should offer at least PVC and ABS, with various gloss levels. Extra points if they offer laser edge or pre-glued versions.

5. Clear Communication

Look for a partner who responds fast, clarifies details, and keeps you in the loop. Time zones and language shouldn’t be barriers.

| Evaluation Factor | What to Check |

| Color Match | Real samples, matching tools |

| MOQ | Flexible starting point |

| Material | PVC, ABS, special finishes |

| Service | Fast response, clear answers |

| Lead Time | Honest and predictable |

You don’t need hundreds of suppliers — just one reliable one.

Where to Find Reliable Custom Color Edge Banding Manufacturers for Wholesale Orders?

Stuck between trading companies, resellers, and “maybe” factories? I’ve been there too.

The best place to find reliable custom edge banding suppliers is through direct factory contact — usually based in China, Turkey, or Eastern Europe — or through verified B2B platforms.

Where I Source From and Why

1. Direct from Factory

This is always my top choice. Better pricing, faster color adjustment, and real production control.

2. Alibaba & Global Sources

Useful for shortlisting suppliers. But make sure to vet them beyond shiny product photos.

3. Trade Fairs and B2B Visits

Events like Interzum or CIFF are great for finding edge banding factories in person. It’s also easier to evaluate quality on the spot.

4. Referral and Industry Networks

Many of my best suppliers came from referrals. Ask people in your industry who they use.

| Source | Pros | Cons |

| Factory Direct | Best price, control | Needs strong communication |

| Alibaba | Easy to browse | Risk of middlemen |

| Trade Shows | Build trust fast | Travel required |

| Industry Referrals | Quality verified | Needs network access |

When in doubt, ask for a video call and live production walkthrough. If they hesitate, walk away.

Conclusion

Custom color edge banding isn’t just a product — it’s part of your brand. Choose wisely, and your furniture will speak for itself.