Furniture production is getting faster, smarter, and more demanding. But many manufacturers still struggle with edge finishing that doesn’t meet design or quality expectations.

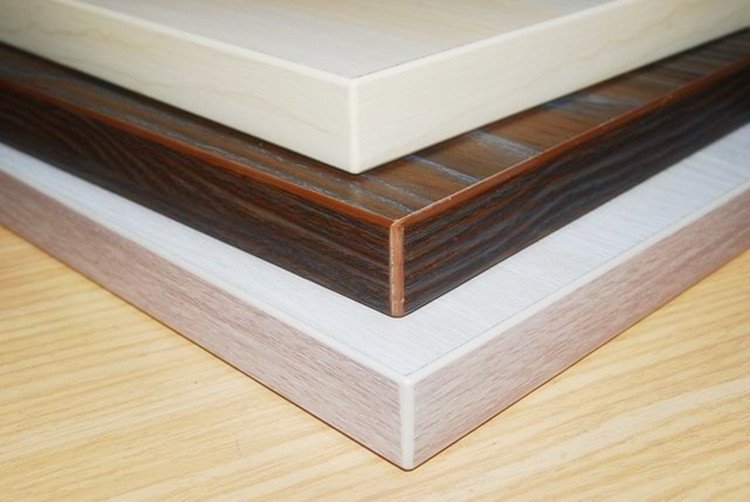

Custom edge banding helps furniture manufacturers solve problems like poor fit, low durability, and mismatched aesthetics by offering made-to-order solutions tailored to their exact needs.

If you’re a furniture manufacturer, you already know how important edge finishing is. Let’s take a closer look at why custom edge banding can make a big difference—and how to choose the right one.

Why Furniture Manufacturers Need Custom Edge Banding Solutions?

When products look unfinished or don’t last, buyers notice. That creates returns and complaints.

Custom edge banding gives manufacturers better control over color, texture, size, and performance to match production needs and market trends.

Matching Product Design

Every furniture line has its own look and feel. Off-the-shelf banding may not match your panels, colors, or grain patterns. Custom options solve that.

Increasing Product Life

Custom banding uses better adhesives and materials. It resists heat, moisture, and wear better. That gives your products a longer life and fewer complaints.

Improving Production Flow

Custom sizes save cutting time. Matching pre-glued solutions reduce extra steps. That makes your whole line run smoother.

| Benefit | Off-the-shelf Banding | Custom Edge Banding |

|---|---|---|

| Color Match | Medium | Excellent |

| Size Accuracy | Low | High |

| Durability | Basic | High |

| Production Fit | Limited | Optimized |

Key Factors to Consider When Choosing Edge Banding for Furniture Production?

Choosing edge banding can seem simple. But when production scales, the wrong choice adds cost and waste.

You should always consider material type, application method, durability needs, and color match when picking edge banding.

Material Compatibility

Not every banding works on every board. For example, MDF and plywood may need different adhesives or flexibility. Ask your supplier what works best.

Application Method

Manual or machine? Hot melt or laser edge? Your process matters. If you’re using PUR glue, your banding must resist heat and hold well.

Durability Requirements

Think about how the furniture will be used. Office furniture needs different resistance than kitchen cabinets. Custom banding lets you tune for specific environments.

Color and Texture Match

This is where custom shines. A good supplier can match your board sample exactly. That gives a premium look at scale.

| Factor | Description | Why It Matters |

| Material | PVC, ABS, wood veneer | Impacts look and strength |

| Thickness | 0.4mm to 3mm+ | Affects edges and feel |

| Adhesion | Hot melt, PUR, pre-glued | Must fit your workflow |

| Finish | Matte, gloss, texture | Should match your brand style |

Top Materials and Specifications for Custom Edge Banding Orders?

Different products need different solutions. A custom order lets you choose the right one.

PVC, ABS, and PP are the most common materials used in custom edge banding, each offering different benefits for different types of furniture.

PVC Edge Banding

PVC is affordable, flexible, and widely used. It’s easy to apply and offers many colors and textures.

ABS Edge Banding

ABS is eco-friendlier and more rigid. It suits high-end or sustainable lines. It’s also good for laser edge banding.

PP Edge Banding

Polypropylene resists chemicals and heat very well. It’s popular in lab or kitchen settings.

| Material | Key Features | Best For |

| PVC | Cost-effective, versatile | Most furniture types |

| ABS | Eco-friendly, strong | Premium products |

| PP | High resistance | Harsh environments |

Custom specs also include:

- Width & Thickness: Matched to your panel size

- Gloss Level: High-gloss, super matte, or anything in between

- Color Matching: From RAL codes to real board samples

How Custom Edge Banding Improves Product Value and Production Efficiency?

Every small detail in production adds up. Edge banding can help you win or lose margin.

Custom edge banding improves value by reducing error rates, saving labor time, and giving your product a high-end finish.

Lower Rework Rates

When banding fits right the first time, there’s less waste and fewer do-overs.

Faster Production

Pre-glued or perfectly sized banding lets your team work faster, especially in automated lines.

Better Look = Better Price

A seamless match boosts perceived value. You can sell the same item for more—or win bigger clients.

| Value Area | With Generic Banding | With Custom Banding |

| Labor Time | Higher | Lower |

| Scrap/Waste | More | Less |

| Product Appeal | Basic | Premium |

| Unit Profit | Low | Higher |

Finding the Right Edge Banding Supplier for Your Furniture Business?

Even with a great design, poor supply ruins results. Not all suppliers understand industrial needs.

Look for a supplier with experience in bulk orders, color matching, and flexible customization to meet your production needs.

What to Ask

- Can they match your sample?

- Can they support high-volume orders?

- Do they have stable lead times?

- Can they adjust specs quickly?

Red Flags

- Limited catalog

- Slow response time

- Inconsistent color matching

As a manufacturer myself, I know how frustrating delays and mismatched materials can be. That’s why I always check for samples, references, and clear communication before starting.

| Criteria | Ideal Supplier | Avoid |

| Color Match | Custom sample match | Generic swatches only |

| Lead Time | 10–20 days | Unknown or slow |

| MOQ | Flexible | Too high |

| Support | Fast reply, technical help | Poor service |

Conclusion

Custom edge banding gives furniture manufacturers more control, less waste, and a better finish—all of which lead to stronger products and happier customers.