I see the problem: designers demand perfect matches but production and supply cause mismatches and returns. I want to help you solve this and win premium orders.

Design-match edge banding means matching color, texture, and gloss between panel face and edge. I will show practical steps to make that happen for Latin American brands and designers.

I will walk you through the meaning, the trends driving demand, the tech that makes matches reliable, a tested workflow to work with brands, and how to build a premium portfolio. Read on to pick the tactics that fit your business.

What “Design-Match” Really Means for Latin American Furniture Brands?

Design-match is more than color. It means visual continuity, tactile harmony, and consistent quality across many panels. Brands want edges that the eye and hand accept as part of the surface. They want no visible seam that breaks the design.

Design-match sells higher price. It reduces returns. It wins design clients. For Latin America, local tastes and export standards both matter. Brands need edges that work in humid climates and still look perfect.

I remember a job where the designer rejected an entire kitchen because the door edges looked slightly darker. The client paid a premium for the wood look. They saw the mismatch first. That taught me how small differences cost big sales.

Dive deeper — the components of a true design-match and buyer expectations

Design-match has three linked parts: color accuracy, texture and sheen, and durability under use. Suppliers must control all three.

Color accuracy. Buyers expect the edge to match panel color within tight tolerance. In high-end work, a ΔE of 2–3 is typical as a goal. I use ΔE specs in sample approvals. Digital print and precise color profiling help meet this target. Industry sources show digital printing on edge tape improves match and reduces revisions.

Texture and tactile match. Some panels have embossed or textured surfaces. The edge must follow that texture or the contrast will show. Suppliers can use embossed edges, textured coatings, or matched veneer to get the feel right. I always ask for a panel sample, not just a color swatch.

Gloss and sheen. A gloss mismatch is obvious. High gloss panels need high gloss edges. Matte panels need low gloss edges. I measure gloss units and include that number in the sample pack. A typical tolerance I use is within 5 gloss units for premium work.

Durability and environmental match. Latin America includes humid zones. A match that fails in two seasons is not a match. I test samples in humidity cycles and report results. Edge materials and adhesives must resist local conditions.

Turnaround and MOQ. Designers want small batches and fast samples. Digital printing and on-demand production make this possible. I keep a sample kit and offer small custom coils where possible. This reduces lead time and turns interest into orders.

Practical checklist I use when a buyer asks for design-match:

- Get a physical panel sample.

- Set color, gloss, and texture targets (ΔE, gloss units).

- Choose technology: digital print, veneer, or coated PVC.

- Run humidity and peel tests.

- Deliver sample pack with test data and lead time.

This process keeps clients confident and lowers the chance of rejected shipments.

Key Aesthetic Trends Driving High-End Furniture Finishes in Latin America (2025–2030)

Design in Latin America blends natural warmth, local craft, and modern simplicity. Buyers want wood tones, soft matte surfaces, and occasional metal or stone accents. They also want products with a story and with greener credentials.

These trends increase demand for matched edges that look natural and feel premium. Edge suppliers must offer wood prints, stone prints, metal-look tapes, and veneer. Market reports show the regional furniture market is growing and premium segments are expanding.

Designers ask for local motifs and custom grain directions. They also test finishes under local light. This changes how I prepare samples.

Dive deeper — specific finish trends, their edge implications, and sample strategies

I track five finish trends and match each to edge strategies.

1. Authentic wood and warm tones

Trend: Consumers prefer warm oak, walnut, and tropical woods.

Edge action: Offer wood-printed PVC and veneer edges with matching grain direction. Use digital print for exact grain alignment on small runs.

2. Matte and soft-touch surfaces

Trend: Matte and soft finishes feel premium and hide wear.

Edge action: Provide matte-coated edges and textured embossing. Control gloss units to match panels (within 5 GU).

3. Mixed-material design (metal + wood + stone)

Trend: Designers mix materials to add contrast.

Edge action: Stock metal-look edges and stone-pattern tapes. For premium mixes, offer laser-ready edges for zero-gap bonding.

4. Small-batch customization and local motifs

Trend: Designers request 50–500 meter runs of custom prints.

Edge action: Invest in digital printing capability or partner with a digital print house. Offer low MOQ options and fast sample timelines.

5. Eco-conscious finishes

Trend: Low-VOC and recycled content gain traction.

Edge action: Source recycled PVC, low-VOC adhesives, and provide MSDS and VOC testing for each SKU.

For each trend I run a localized sample program. I send a kit with:

- 6 edge samples that match the panel.

- A short test report (ΔE, gloss, humidity soak).

- Suggested machine settings and adhesive pairing.

This kit converts interest into orders. It also shortens approval cycles with designers and brands.

How Edge Banding Technology Ensures Perfect Color, Texture, and Gloss Matching

Technology removed much of the guesswork. Digital UV inkjet printing on edge tape gives precise color and grain. Laser/zero-gap systems provide cleaner joints. Measuring instruments control color and gloss. These tools let suppliers meet tight specs.

Adhesive tech matters too. PUR adhesives give stronger bonds in humid climates. They also reduce delamination risk that ruins a match. Reports show adoption of higher-performance adhesives and digital printing in the edge market.

I use tech to prove matches. I measure and share real numbers with buyers.

Dive deeper — technologies, measurement standards, and implementation tips

Digital printing on edge tape.

Digital UV inkjet can print full-grain patterns, subtle knots, and stone veins. It works for low MOQ. It allows exact color profiling for specific panels. I print a test strip and cut it into samples. I send these with ΔE and gloss readings.

Embossing and texture matching.

Embossed rollers can add texture that follows a printed grain. Use registration controls so print and texture align. This step avoids the “flat print on textured panel” problem.

Laser / zero-gap edge bonding.

Laser edge systems can trim and smooth edges for nearly invisible joins. They work well with thin edge tapes and veneer. This tech improves perceived value and reduces visible seams.

Measurement and specs.

- ΔE for color. Aim for ΔE ≤ 2–3 for premium work.

- Gloss units for sheen. Measure at standard angles (60°) and match within a tight band.

- Peel and shear tests for bonding strength. Include humidity cycle results for tropical markets.

Adhesive pairing.

Select adhesives for material type and climate. PUR works well for PP/ABS and for humid climates. Some EVA formulas are acceptable for dry regions. I include adhesive pairing notes with each sample.

Practical implementation steps I use.

- Get the panel sample.

- Select candidate edge tech: digital print, veneer, or coated PVC.

- Produce printed sample with matching texture.

- Test ΔE, gloss, and humidity peel.

- Send full sample kit and machine settings.

These steps reduce back-and-forth and show competence. They also help justify price for premium edges.

Steps to Build a Design-Match Workflow with Furniture Brands and Designers

A clear workflow creates trust. Brands want a repeatable path from sample to shipment. I build a five-step workflow that I give to every new client.

The workflow lowers approval time. It also reduces errors and returns. Designers like clear steps and fast samples.

I use this workflow with local factories and export clients.

Dive deeper — a practical, step-by-step workflow and templates to use

Step 1: Sample intake and requirements

Ask for a physical panel sample, target ΔE, target gloss, and expected environment (e.g., coastal humidity). Record project name and delivery date. I use a simple intake form that designers fill online.

Step 2: Material and technology selection

Choose between digital print, veneer, coated PVC, or metal-look tape. Decide on texture embossing and adhesive pairing. I provide a recommended tech sheet for each option.

Step 3: Sample production and testing

Produce a set of 3–6 edge samples. Run ΔE, gloss, and 48-hour humidity peel tests. Document machine settings used (glue temp, speed, pressure). I include photos and test data in the sample pack.

Step 4: Client approval and minor revision loop

Send sample pack and request sign-off within a set window (7–10 days). If minor tweaks are needed, adjust print profile or texture and resend a revised sample. Limit revision rounds to two to keep timelines tight.

Step 5: Pre-production and QA

Before full runs, produce a pilot batch (e.g., 100–200 meters). Run random QA tests and keep records. For ongoing orders, attach batch numbers, adhesive lot numbers, and a QA certificate.

I also use templates:

- Sample intake form.

- Sample test report (ΔE, gloss, humidity).

- Machine setting cheat sheet.

- Pilot batch QA certificate.

These templates save time. They also show buyers that I operate professionally. For export clients, the QA packet often seals the deal.

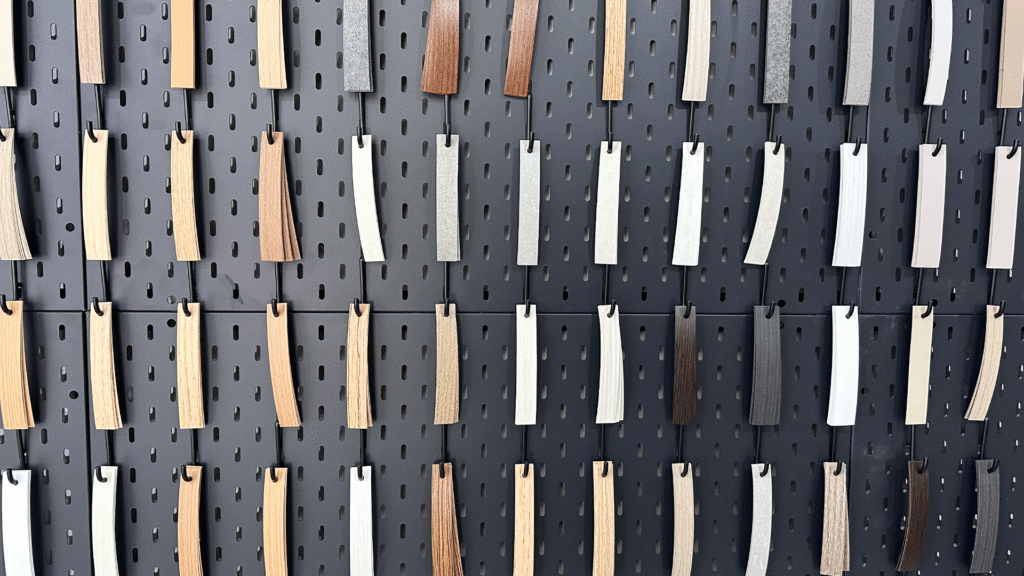

Building a Premium Edge Banding Portfolio for Latin American Markets

A premium portfolio showcases aesthetics, tests, and supply options. It must include regional palettes and the ability to run small custom jobs. It must also show environmental credentials.

I recommend three tiers: standard, designer, and premium. Each tier has clear specs, lead times, MOQ, and test data. This clarity wins buyers.

I present tiers and sample packs to buyers. That approach makes purchasing simple.

Dive deeper — product mix, packaging, pricing, and go-to-market ideas

Product tiers and what to include

- Standard: cost-effective PVC coils. Include color swatches and basic specs. MOQ higher but price lower.

- Designer: digital-printed patterns, matte and satin finishes, small-run options. Include ΔE and gloss data.

- Premium: veneer, laser-ready tapes, metal-look options, full test reports, and sustainability documentation (MSDS, VOC tests, recycled content).

Packaging and sample kits

Create country-specific sample kits. For Brazil include warm oak and mid-tone walnut. For Chile include neutral modern palettes. Each kit has 8–12 edge samples, a one-page test summary, and machine-setting notes.

Pricing and MOQ

Offer clear pricing bands and low-MOQ options for designer and premium lines. Price digital printing per meter with a setup fee and a low MOQ discount. For veneer, offer bundled pricing with adhesive recommendations.

Marketing and sales tools

- Use before/after photos.

- Publish short case studies showing reduced returns or faster approvals.

- Offer an online sample request form with upload capability for panel photos.

Local stock and logistics

Keep a small stock of top-selling coils in-country. Offer 24–72 hour sample shipping. For custom prints, give realistic lead times and track them closely.

Training and after-sales

Provide quick machine-setting guides and a troubleshooting sheet for common match issues. Offer short virtual training sessions for large buyers.

This mix helps suppliers win both small design firms and larger chain customers. It also supports export clients who demand documented quality.

Conclusion

I recommend clear tiers, fast matched samples, measured test data, and regional palettes. Do this and you will win high-end Latin American clients.

Data sources and links

- MarkNtel Advisors — Latin America Furniture Market (2025–2030 forecast). https://www.marknteladvisors.com/research-library/latin-america-furniture-market.html (MarkNtel Advisors)

- IMARC Group — Edge Banding Materials Market (market size and forecast). https://www.imarcgroup.com/edge-banding-materials-market (IMARC Group)

- ResearchAndMarkets — Edge Banding Materials Market – global report. https://www.researchandmarkets.com/reports/5977674/edge-banding-materials-market-global-forecast (Research and Markets)

- Agfa / Industry notes — Printing furniture edge bands with UV inkjet (digital printing use cases). https://www.agfa.com/printing/news/printing-furniture-edge-bands-uv-inkjet/ (Agfa)

- Framatech — 5 Things to consider when matching your PVC edgebanding (practical matching tips). https://www.framatech.com/blogs/the-ultimate-edgebanding-resource-hub/5-things-to-consider-when-matching-your-pvc-edgebanding (Frama-Tech)