I see the problem: panels peel, edges bubble, and customers complain. I want to help you stop that fast.

Edge banding must resist moisture and heat. I will show practical steps to choose materials, adhesives, and processes for South America.

We hit a lot of edge failures in hot, wet places. I will explain why this happens. Then I give clear fixes you can use in your shop today. Read on to cut rework and complaints.

Why Humidity and Heat Challenge Edge Banding Performance in South America?

I remember a run of cabinets that came back warped after one rainy season. The glue failed fast. That is common in humid climates.

Humidity and heat weaken bonds and make materials expand. This causes delamination, bubbles, and gaps. South America has large zones with high humidity and strong sun. These conditions stress edge banding and adhesives more than in dry places.

Dive deeper — how moisture and heat damage edges (and what to look for)

Humidity and heat act on three parts of the edge system: the substrate (MDF, particleboard), the edge band material (PVC, ABS, PP, veneer), and the adhesive. Each part reacts differently to moisture and temperature. This mismatch makes failure more likely.

- Substrate movement. Wood-based panels absorb water. They swell and shrink. This changes edge dimensions. If the edge band cannot follow that change, it peels.

- Thermal expansion. Plastics and wood expand at different rates when heated. Repeated day/night cycles and sun exposure cause stress where the adhesive sits.

- Adhesive sensitivity. Some hot-melt adhesives absorb water or soften at higher temps. That cuts bond strength. Water can also cause chemical changes like hydrolysis in some adhesives.

- Vapor pressure and trapped moisture. When edges are sealed poorly, moisture can become trapped. Trapped moisture builds pressure under the edge film. That leads to bubbling and lifting.

I check these signs in the shop:

- Tiny bubbles after a week of high humidity.

- Edges that lift at corners or seams.

- Soft or powdery glue line when scraped.

- Boards that are thicker at the center than the edges.

I use simple tests. I keep sample panels in a humidity chamber or in local outdoor shade for a few days. If I see bubbles or edge lift, I change materials or glue. Scientific reviews show humidity and temperature together cause more failures than either factor alone. This is important when choosing adhesives and materials for tropical climates.

| Failure mode | Cause | Quick check |

|---|---|---|

| Delamination | Moisture + poor adhesive | Peel test on sample |

| Bubbling | Trapped moisture or heat | Visual after humidity exposure |

| Edge shrinkage | Material change after production | Measure before/after humidity |

| Glue softening | Wrong adhesive for climate | Finger test on glue line |

These points are why we need targeted choices in South America. I will give those choices next.

Common Edge Banding Failures Caused by Moisture and Temperature Fluctuations?

I have seen the same five failure types repeat. They cost time and money.

The top failures are delamination, bubbling, corner lift, color mismatch after swelling, and edge cracking. Each has a specific cause. You can stop most with the right material and process.

Dive deeper — root causes and quick remedies

Delamination (edge peel).

- Root cause: Moisture weakens the adhesive or the interface. Thermal cycles add shear stress. Studies confirm that moisture plus heat is a main cause of delamination.

- Remedy: Use adhesives with proven moisture resistance. PUR adhesives show better long-term water resistance than EVA in many tests. Also ensure correct glue film thickness and machine temperature.

Bubbling and blistering.

- Root cause: Trapped moisture or rapid heating of the glue layer. Moisture turns into vapor and creates pressure.

- Remedy: Store materials in controlled humidity. Allow panels to acclimate. Use gradual heating and proper cooling steps after banding.

Corner and end lift.

- Root cause: Poor overlap, wrong band thickness, or insufficient edge prep. Corners are the most stressed points during movement.

- Remedy: Use corner rounding tools. Apply consistent pressure during cooling, and finish with light iron pressing when needed.

Color change or edge shrinkage.

- Root cause: Some PVC strips shrink or change gloss in heat and humidity. This causes mismatch with the panel.

- Remedy: Select stable edge materials. Test samples under local climate conditions before full runs.

Adhesive chalking or softening.

- Root cause: Hydrolysis or plasticizer migration in certain adhesives under heat and humidity.

- Remedy: Choose adhesives formulated for humidity exposure, like certain PUR grades. Test with peel and shear tests after humidity cycling. Industry guides list PUR and specially formulated high-temperature EVA formulas as options.

I use a checklist during production:

- Verify panel moisture content.

- Check edge material batch for shrinkage spec.

- Set glue temp and speed for local conditions.

- Run a 48-hour humid test on samples.

- Log failures and change one variable at a time.

This method cuts repeat failures. It also gives data to justify material upgrades to procurement.

Choosing the Right Edge Banding Materials for Humid and Tropical Conditions?

I prefer simple rules: pick stable materials and test them locally. Do not assume what works in dry climates works here.

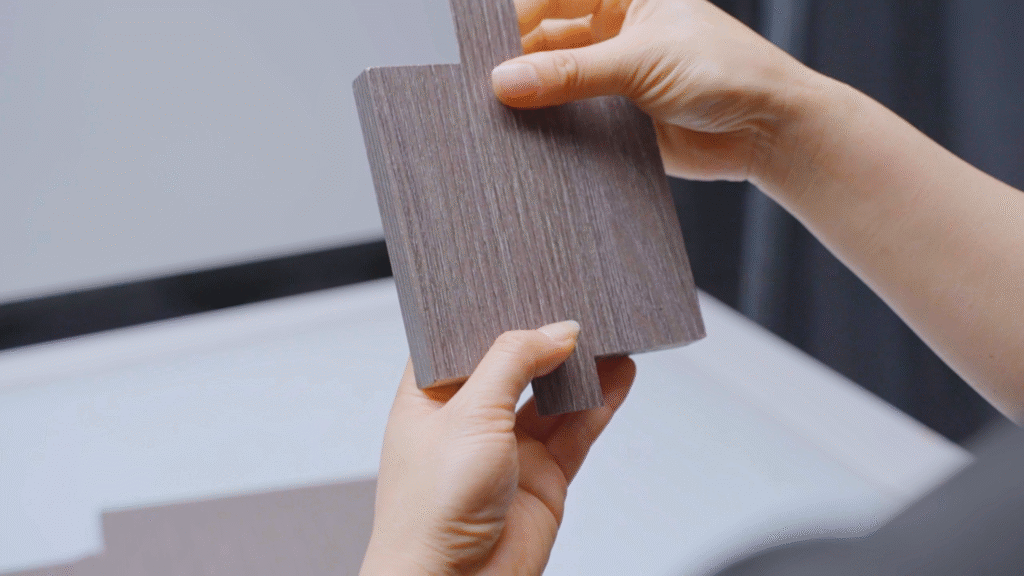

PVC is common and cost-effective. ABS and PP can be better for impact and heat. Real wood veneer needs good sealing to resist moisture. Always test before a big run.

Dive deeper — material pros, cons, and selection table

I compare materials on four points: moisture resistance, dimensional stability, heat tolerance, and cost. Use the table below to guide choices.

| Material | Moisture resistance | Dimensional stability | Heat tolerance | Cost |

|---|---|---|---|---|

| PVC | High | Good | Moderate | Low |

| ABS | High | Better than PVC | Better | Medium |

| PP | Very high | Very good | Good | Medium |

| Veneer (wood) | Low → needs seal | Low (moves) | Low | High |

| Acrylic/PMMA | Moderate | Good | Moderate | High |

PVC (polyvinyl chloride).

- PVC works well in humidity if it is good quality. It resists water and will not swell like wood. But lower grade PVC may shrink or warp under heat. I pick PVC with low shrink spec and check ∆L after humidity tests. Industry sources confirm PVC remains widely used in regions where cost matters.

ABS (acrylonitrile butadiene styrene).

- ABS offers better impact resistance and more stable behavior in heat. It is a good upgrade from basic PVC when budget allows.

PP (polypropylene).

- PP shows strong dimensional stability and humidity resistance. It is a good choice for hot, wet climates but it can be harder to glue; you need the right adhesive and surface prep.

Veneer and real wood.

- Veneer looks premium but the wood will move. You must seal end grain well and use a moisture-stable substrate. For tropical zones I avoid bare veneer on exposed edges unless the design and finish control moisture.

I always run local field tests. I expose samples to local weather and to a humidity chamber if I can. I also test different thicknesses and radii. Small changes in radius and thickness affect stress at the glue line.

For export orders, I add a note about climate and recommend PUR adhesives when the buyer expects long use in humid climates. Market reports show South America furniture demand is growing. That means clients will pay more for fewer complaints when you prove durability.

Best Practices for Adhesive Application and Edge Banding Installation in Humid Environments?

Good glue and good process beat cheap material choices. I always set my machine for the climate and log settings.

Use adhesives suited for moisture. Control temperature, pressure, and cooling. Prep the substrate. Store everything dry.

Dive deeper — step-by-step process and testing table

1. Choose the right adhesive.

- EVA (Ethylene-Vinyl Acetate): Cheap and fast. Works well for many uses. But some EVA grades are sensitive to long term humidity.

- PUR (Polyurethane Reactive): Better moisture and heat resistance. It forms a chemical bond with the substrate. This makes it top choice where humidity is a problem. Industry guides recommend PUR for high-moisture zones.

2. Set machine parameters for your climate.

- Lower glue pot temp can reduce plasticizer migration in some formulas.

- Slow the feed speed slightly in very humid days. This gives better glue open time and wetting.

- Increase pressure and contact time when using thicker edges.

3. Prepare the substrate and edges.

- Sand the board edge lightly to open pores on veneered or melamine boards.

- Remove dust thoroughly. Dust reduces bond area.

- Preheat panels a few degrees on cold, humid mornings.

4. Store and acclimate materials.

- Keep edge coils and panels in a dry room if possible. Aim for stable relative humidity before banding.

- Let materials sit in the production room for 24–48 hours if they came from a different climate.

5. Cooling and finishing.

- Use cooling rolls or fans after pressure rollers. Rapid cooling locks the bond.

- Trim and finish edges after the glue sets. Avoid re-heating the glue line excessively.

Testing plan (simple table):

| Test | Purpose | Pass criteria |

|---|---|---|

| 48-hour humidity soak | Check delamination | No peeling / <2mm lift |

| Hot cycle (40°C day) | Check thermal stress | No bubbles |

| Peel test (180°) | Adhesive strength | Meets spec (supplier data) |

| Visual gloss check | Color stability | Within tolerance ΔE |

I track failures and adjust one factor at a time. That gives me clear cause and effect. If problems persist, I move to a higher grade adhesive like PUR. PUR costs more. But it often saves money by reducing rework.

Long-Term Maintenance and Quality Checks for Edge Banding in Tropical Regions?

I advise customers to plan for maintenance. Edge checks on a schedule catch issues before they grow.

Inspect edges seasonally. Clean properly. Train installers and end users on best care.

Dive deeper — maintenance schedule, inspection steps, and templates

I give my customers a three-step maintenance plan: Inspect, Clean, Record.

Inspect (every 3–6 months).

- Look for small lifts, bubbles, or color change. Pay attention to kitchens and bathrooms. These zones get wet more often.

- Check corners and ends. They show stress early.

Clean (monthly where used).

- Use mild soap and water. Avoid high-alcohol cleaners that attack some plastics.

- Dry edges immediately after cleaning.

Record and act (ongoing).

- Keep a simple log with dates and photos. This helps find patterns. If many units show the same problem, adjust the materials or process.

I also recommend the workshop do a yearly audit:

- Run peel and shear tests on random samples.

- Check storage humidity with a cheap hygrometer.

- Review adhesive batch numbers and machine logs.

If you sell to export markets, document your process and tests. Export buyers ask for proof. A test log, humidity cycle results, and adhesive spec sheets are persuasive.

Finally, I give simple care advice to owners:

- Avoid leaving wet cloths on edges.

- Do not expose furniture to prolonged sun on the edge profile.

- For damaged edges, repair early. Small fixes cost less.

This approach reduces complaints and shows professionalism. It also builds trust when you sell to distributors and designers.

Conclusion

Follow these simple, climate-aware rules: choose stable materials, use moisture-resistant adhesives, control process, and inspect often.

Data sources and links

- Peng H., Effect of Temperature and Humidity Coupling on the Failure Properties, PubMed Central. (PMC)

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC11013269/ - Tian W., Delamination of Plasticized Devices in Dynamic Service, PubMed Central. (PMC)

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10972266/ - Dachev D., Towards Reliable Adhesive Bonding: A Comprehensive Review, PubMed Central. (PMC)

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC12195023/ - Hotmelt / industry guide, Adhesives for Edgebanding (Kleiberit and product notes). (Hotmelt.com)

https://www.hotmelt.com/collections/application-edgebanding - Industry guide, EVA vs PUR Edge Banding Hot Melt Adhesives and recommendations. (Shaosen)

https://hotmeltmanufacturer.com/the-ultimate-guide-to-choosing-the-best-glue-for-pvc-edge-banding/ - Market report summary, Latin America Furniture Market (2024–2030) (MarkNtel / Research summaries). (MarkNtel Advisors)

https://www.marknteladvisors.com/research-library/latin-america-furniture-market.html - South America furniture market listings and reports (MarketResearch / ResearchAndMarkets summaries). (市场研究网)

https://www.marketresearch.com/seek/Furniture-South-America/