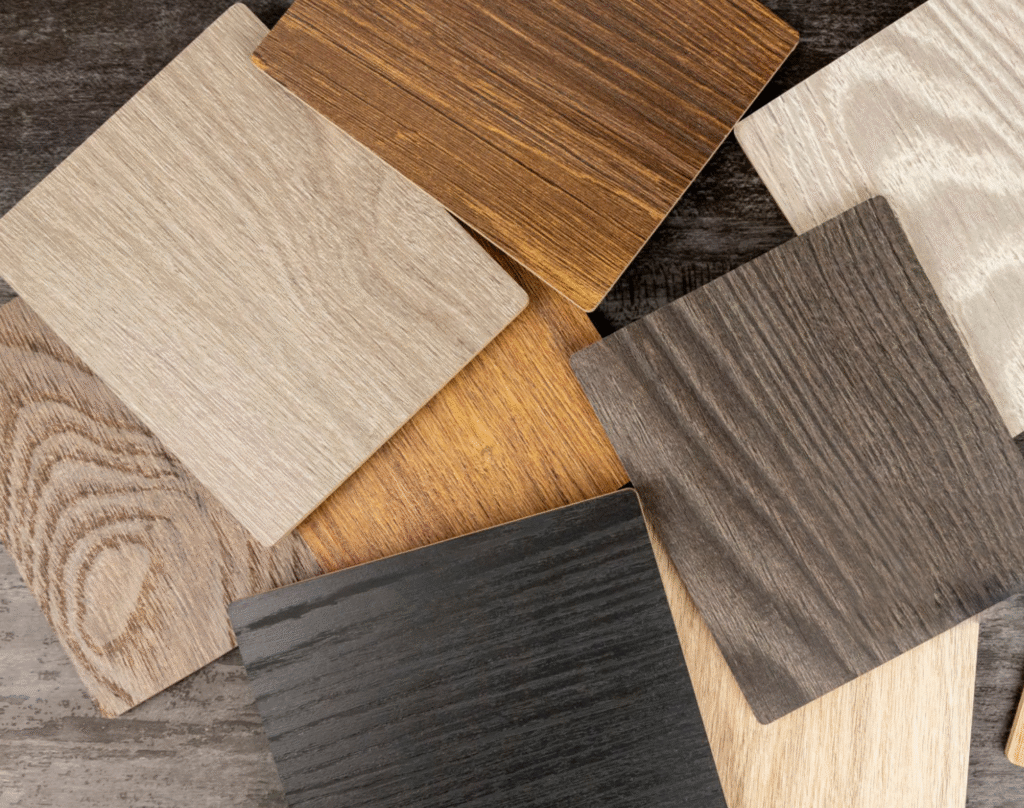

Problem: color mismatch wrecks a job. I felt that loss. So I made a short, practical guide to the ten patterns sellers push and why they work.

The most promoted 2025 edge-band patterns are natural woodgrains (oak, walnut), uni solids (pure/Arctic white, anthracite), concrete/stone looks, maple/beech variants, and metal/brushed finishes — reflected in major vendor catalogs and fair launches. (kronospan.com)

I will walk you through why some colors repeat across brands. I will name the ten most promoted patterns. I will show how manufacturers pick them. Read on. I use firm sources and link them at the end.

Understanding Why Certain Edge Banding Colors Dominate the Market?

Problem: buyers see many colors and freeze. I saw that happen at trade fairs. I want to clear the fog in one short answer.

Manufacturers push woodgrains, unicolors, and stone/metal effects because these match most panels, sell faster, and reduce rejection on the shop floor. (egger.com)

What drives dominance

I look at three drivers. First, matchability. Shops want an edge that blends with the board. Second, stock and lead time. Distributors list items they keep in stock. Third, trends and marketing. Big brands promote a short list so distributors buy that list. Each driver reduces risk for fabricators.

Quick table of drivers

| Driver | Why it matters | Example effect |

|---|---|---|

| Matchability | Reduces visible joints | More oak & walnut edges sold |

| Stock / Logistics | Faster lead time | Distributors keep top unicolors |

| Marketing / Catalogs | Guides spec decisions | “Most Preferred” lists shape demand |

| Trade fairs | Show latest combos | Booths highlight wood + matte uni |

I checked major vendor collections. Kronospan publishes a “Most Preferred” set that centers on oak and uni colors. EGGER’s Decorative Collection also highlights wood, uni and stone replicas. Duratex uses locality (Brazilian tastes) to promote specific walnut/oak names. These vendor choices show how catalogs steer the market. (kronospan.com)

My take: when suppliers speak the same names, buyers repeat them. That creates a feedback loop. I once lost a job because my edge wasn’t the vendor’s promoted code. I learned to match supplier catalogs fast.

The Top 10 Most Commonly Promoted Edge Banding Color Patterns in 2025?

Problem: you need a concrete list, not vague trends. I give the ten patterns below in plain names and show where vendors use them.

Top 10 (most promoted, not ranked by sales): Pure/Arctic White (uni); Halifax/White Halifax Oak family; Natural Walnut (various “walnut” names); Anthracite / Black Matt; Concrete / Beton Grey; Maple / Light Wood; Sonoma / Light Oak variants; Natural Beech / Birch; Dark Walnut / Nogueira-style; Brushed Metal / Metal-look. (egger.com)

Top 10 explained (table)

| Pattern (common label) | Typical use case | Example vendor name / decor |

|---|---|---|

| Pure / Arctic White (uni) | Modern kitchens, trims | EGGER “Pure / White” (uni). (egger.com) |

| Halifax Oak (white / natural) | Scandinavian & modern furniture | EGGER “Halifax Oak” family. (egger.com) |

| Natural Walnut | Warm kitchens, offices | Kronospan / EGGER walnut decors. (Proadec) |

| Anthracite / Black Matt | High-contrast modern fronts | Kronodesign uni darks. (kronospan.com) |

| Concrete / Beton Grey | Industrial / stone-look designs | EGGER stone replicas. (egger.com) |

| Maple / Light Wood | Light cabinets, retail fitouts | Kronospan & Finsa light wood decors. (Proadec) |

| Sonoma / Light Oak variants | Affordable oak look | Kronospan “Light Sonoma Oak” listed in swatches. (kronospan.com) |

| Beech / Birch (natural beech) | Classic interiors | Duratex & Finsa include beech-like decors. (Duratex Madeira) |

| Dark Walnut / Nogueira-style | Premium warm finishes | Duratex Nogueira family. (Madeira NIT) |

| Brushed Metal / Metal-look | Accent edges and worktops | EGGER & Kronospan metal finishes. (egger.com) |

I built this list by cross-checking catalog highlights, “most preferred” swatches, and recent expo launches. Where vendors group the same decors across catalogs, I marked the pattern as “most promoted.” (kronospan.com)

Key Factors That Influence the Popularity of Edge Banding Designs?

Problem: choices are not random. I list the real selection drivers you will face.

Main factors: visual match, texture sync, stock availability, price, trend cycles, and regional taste — each shapes which colors vendors push. (egger.com)

Break down of each factor

I treat each factor in turn and give practical signals you can watch for.

1) Visual match and texture sync

I watch whether the edge uses the same grain direction and pore. Modern decors sync micro-pore with panel faces. This reduces visible seams. Vendors now publish “Interior Match” recommendations to help fabricators pick matching edges. (egger.com)

2) Stock and logistics

Distributors keep a short list. Items on that list sell more. I have seen local suppliers carry white, oak and anthracite as their top stocked edges. This availability shapes what shops use.

3) Price and SKU rationalization

Suppliers cut SKUs to control cost. Fewer edge codes and broad matches reduce inventory overhead. Big producers publish “Most Preferred” collections to simplify this. (kronospan.com)

4) Regional taste and festival cycles

In Brazil, for example, Duratex launched the “Harmonia” and named patterns (Gianduia, Nogueira, Carvalho) that reflect local taste. That pushes those names into local distributors’ top lists. (Duratex Madeira)

Table — factor → what to watch for

| Factor | What I watch for as a buyer |

|---|---|

| Match / Texture | Vendor “match” guides and pore type |

| Stock | Distributor stock lists and lead times |

| Price | SKU reductions and “Most Preferred” packs |

| Trend | Trade fair highlights and catalog launches |

| Local taste | Local catalog names and expo launches |

I use catalogs and fair reports to read these signals. That is why vendor PDFs and expo pages are good evidence. (egger.com)

How Manufacturers and Distributors Select “Bestseller” Edge Banding Colors?

Problem: you want to know how a color becomes “bestseller.” I explain the selection path step by step.

Manufacturers pick bestseller lists by combining sales data, trade-fair feedback, designer briefs, and stock optimization; distributors convert those lists into stocked SKUs. (kronospan.com)

The selection workflow (short)

I map the common workflow used across large vendors.

Steps vendors follow

- Sales signals: measure which codes ship most.

- Trade feedback: test new decors at fairs and measure interest.

- Catalog curation: put winners into a “Most Preferred” pack.

- Distributor roll-out: recommend top list for stocking.

- SKU pruning: phase out low-moving edges.

Evidence from catalogs and packs

Kronospan curates a “Most Preferred” Kronodesign set to simplify buying choices. EGGER offers the Decorative Collection and design tools that show favored matches. Duratex promoted a 2024–2025 collection around local tastes. These published choices tell us how vendors formalize “bestsellers.” (kronospan.com)

Table — metric vs role in selection

| Metric | Role in choosing bestsellers |

|---|---|

| Shipment volume | Primary proof of demand |

| Sample requests | Early indicator of adoption |

| Trade fair interest | Shortlist new decors |

| Distributor feedback | Confirms stocking feasibility |

I advise buyers to ask suppliers for their “Most Preferred” swatch packs. I do that before quoting jobs. The pack often matches what the distributor will ship quickly. (krono-shop.com)

Practical Tips for Choosing the Right Edge Banding Color for Your Furniture Projects?

Problem: you need action, not theory. I give clear steps you can use on the next job.

Tip highlights: use vendor “match” guides, order physical samples, prioritize stocked SKUs, test under real light, and favor widely used decors for fast replacement. (egger.com)

Step-by-step checklist (my practical recipe)

I list steps I follow before I commit to a color.

1) Start with the vendor match code

Ask the panel supplier for the “Interior Match” or printed match code. This reduces surprises. EGGER and Kronospan publish match guides and apps to check combos. (egger.com)

2) Order small samples

I order a 100 mm edge strip and a 100 mm panel sample. I put both under the project light. I photograph the pair. This step catches tone shifts that a screen hides.

3) Pick stocked SKUs where possible

I check distributor stock lists. If a color is in stock locally, I pick it. Fast fulfillment reduces delay and rejects. This is a frequent point at AWFS and regional fairs. (ctedgeband.com)

4) Consider texture and finish

I check pore direction and sheen. Matte unicolors hide seams. Synchronized pores give a natural look. Vendors list textures in catalogs. (Finsa)

5) Communicate the exact code

I send the exact vendor code to the shop and the supplier. I ask for a sample approval photo before production.

Table — checklist

| Step | Action |

|---|---|

| Vendor match | Get match code from supplier |

| Samples | Order physical samples |

| Stock check | Confirm local stock/lead time |

| Texture | Verify pore and sheen |

| Confirmation | Send code and sample photo to shop |

I apply these steps and avoid rework. I also keep a short “go-to” list of ten edge codes that I use often. That list is drawn from vendor “most preferred” packs and local stock. If you want, I can draft a starter ten-code list for your region next.

Conclusion

I gave the ten most promoted edge patterns, why they repeat, and clear steps to pick them. Use supplier match guides and samples.

Data sources

- EGGER — Decorative Collection 24+ (Decor guides & decor combos). https://www.egger.com/en/furniture-interior-design/decorative-collection/ (egger.com)

- EGGER — Halifax Oak decor page / decor combos (Interior Match references). https://www.egger.com/en/flooring/decors/1801510?lci=Y29sbD0xNzAxJm5jPXJvdzEg (egger.com)

- Kronospan — Kronodesign Most Preferred / Global swatch listings. https://kronospan.com/en_US/decors/by_collection/kronodesign/most-preferred/ (kronospan.com)

- Kronodesign / Kronospan swatch list (global collection / sample references). https://www.proadec.com/pt/downloads/kronospan-kronodesign-2023-2027/ (Proadec)

- Duratex — Expo Revestir 2024 / Coleção Harmonia and 2025 catalog PDF. https://www.duratexmadeira.com.br/mostras-de-decoracao/expo-revestir-2024/ | https://duratex-madeira-prd-images-bucket.s3.amazonaws.com/2025/02/CATALOGO-2025-DURATEX.pdf (Duratex Madeira)

- Finsa — Colour chart 2025–2029 (Calypso / Bolero textures & color chart). https://www.finsa.com/documents/d/guest/carta_de_color_2025-es | https://www.finsa.com/en/fp/stdio-466b-calyps/studio/rojo-tassili/calypso (Finsa)

- CT Edgeband — Edge banding trends (AWFS 2025 summary: realistic woodgrains, matte neutrals, fulfillment). https://www.ctedgeband.com/blog/top-5-edgebanding-trends-from-awfs-2025 (ctedgeband.com)