Is your edge banding process holding back your furniture quality?

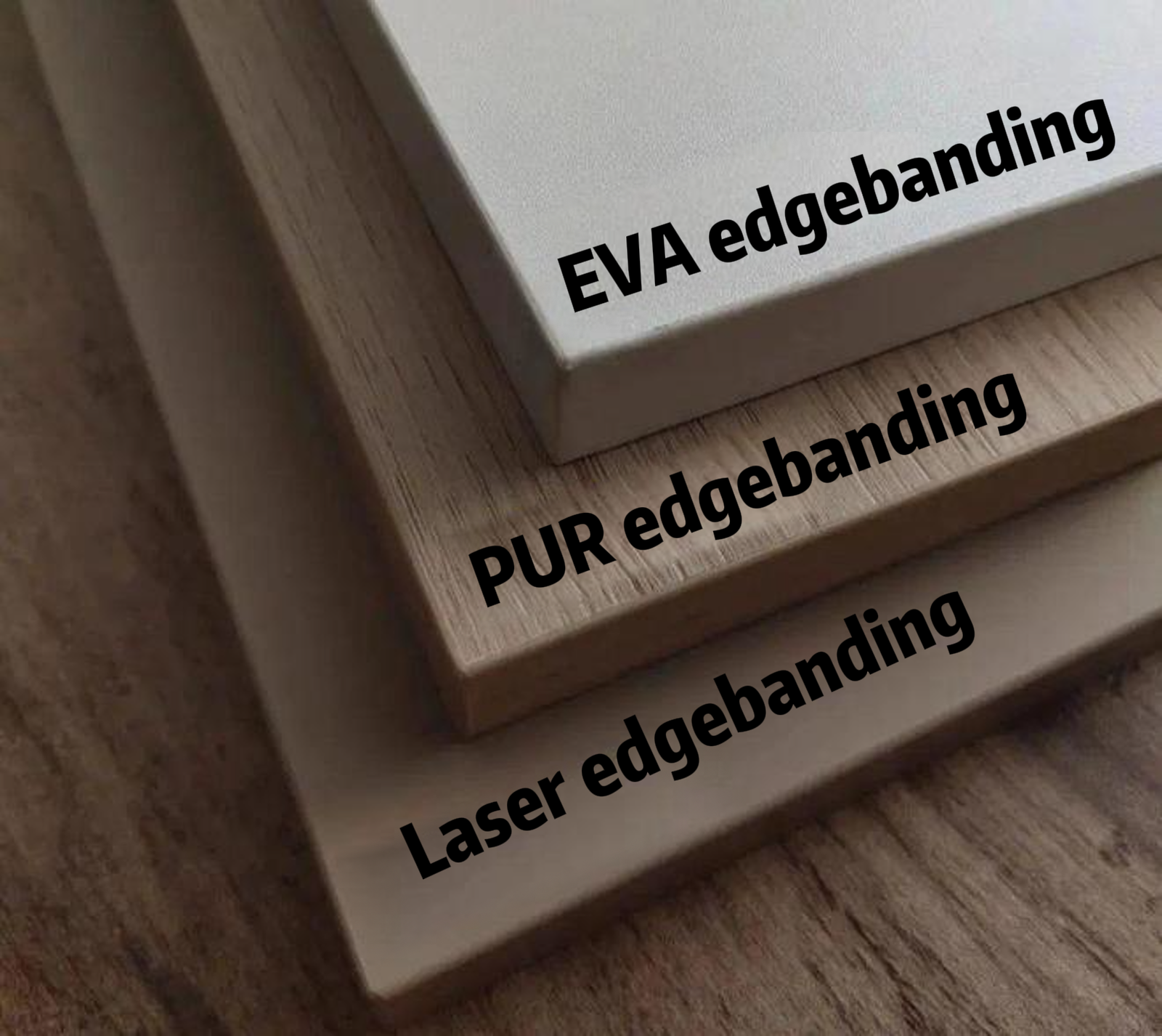

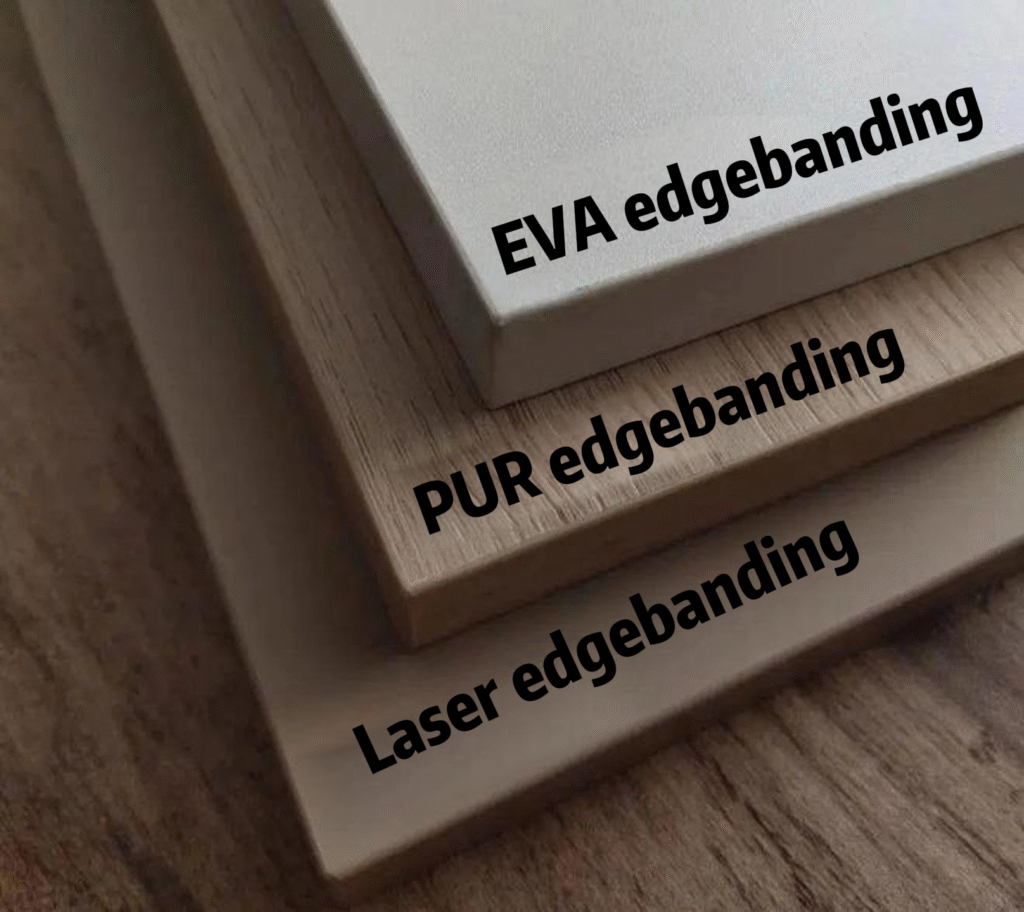

Hot melt adhesive edge banding uses glue to bond tape to board edges, while laser edge banding uses laser or hot air to melt a pre-applied polymer layer—resulting in a seamless finish with no visible glue lines.

If you’re like most furniture manufacturers, you’ve probably wondered if it’s time to upgrade your edge banding method. Keep reading—I’ll break down exactly how both options work, what makes them different, and how to decide which one fits your production line.

What Is Hot Melt Adhesive Edge Banding and How Does It Work?

Messy glue lines and weak bonding? That’s often the result of poor edge banding—not your board quality.

Hot melt adhesive edge banding is a traditional method where hot glue is applied to the back of edge banding tape, then pressed onto the board edge by a machine or manually.

How It Works in Real Production

I’ve seen this method used in almost every medium-size factory I’ve visited. It’s popular for one simple reason—it’s affordable and easy to set up. But it’s not flawless.

Step-by-Step Breakdown

Gluing

A hot melt adhesive (usually EVA or PUR glue) is heated and applied to the edge banding tape.

Bonding

The tape is pressed against the panel edge with rollers while the glue is still hot.

Trimming & Buffing

Excess tape is trimmed. Buffing tools smooth the edge and remove glue marks.

Pros and Cons Table

| Pros | Cons |

| Cost-effective and simple setup | Visible glue line |

| Compatible with most materials | Glue aging over time |

| Easy to repair or rework | Not fully waterproof (EVA glue) |

If your production doesn’t require ultra-premium finish or moisture resistance, hot melt works just fine. I’ve helped clients get great results with a well-tuned hot melt line. But if edge quality is your brand’s core selling point, keep reading.

What Is Laser Edge Banding and Why Is It Considered Seamless?

Tired of dealing with glue mess and color mismatch on the edge? Laser edge banding could solve that for good.

Laser edge banding uses laser, plasma, or hot air to melt a co-extruded polymer layer on the edge banding tape itself, bonding it directly to the board—no extra glue needed.

A Closer Look at Seamless Technology

I’ve toured factories that upgraded to laser edge banding, and the first thing I noticed was the clean, uninterrupted look on every panel. The transition from the surface to the edge was so smooth, you could barely tell it was a separate piece.

Key Steps in the Laser Process

Pre-applied Functional Layer

The edge banding tape has a special polymer layer (like PMMA) pre-applied.

Laser or Hot Air Activation

A focused energy source melts this layer instantly.

Fusion Bonding

The melted layer bonds directly to the board without separate glue.

What Makes It Seamless?

No Glue Line

Since the bonding comes from the tape itself, there’s no exposed glue.

Tighter Fit

The melted layer flows into the micro gaps, giving a flush and sealed finish.

Better Water and Heat Resistance

This process works well in kitchens, bathrooms, and premium office furniture.

| Pros | Cons |

| No glue line, seamless appearance | High machine cost |

| High durability and moisture proof | Requires special edge tape |

| Low maintenance, no glue tank needed | Not ideal for very small factories |

If your brand positions itself as high-end or exports to demanding markets like Europe, laser edge banding gives you that competitive edge—literally.

Hot Melt vs. Laser Edge Banding: What’s the Difference?

Are you stuck between cost and quality? You’re not alone. Let’s settle the debate with a clear comparison.

Hot melt and laser edge banding differ mainly in bonding method, finish quality, cost, and maintenance. Hot melt uses glue; laser uses a built-in polymer. Each has strengths for different production needs.

Side-by-Side Comparison

1. Bonding Technology

Hot melt: Applies glue manually or by machine.

Laser: Fuses tape directly with no added glue.

2. Finish Quality

Hot melt: May leave glue lines, especially on dark boards.

Laser: Seamless look, perfect for high-gloss or solid color panels.

3. Durability

Hot melt: Good for dry environments.

Laser: Better for moisture- and heat-prone areas.

4. Setup and Maintenance

Hot melt: Glue tanks require daily cleaning.

Laser: Easier maintenance, but higher upfront investment.

| Feature | Hot Melt Adhesive | Laser Edge Banding |

| Bonding method | EVA or PUR glue | Laser-activated layer |

| Finish | Visible glue line | Seamless, no glue line |

| Durability | Moderate | High |

| Investment cost | Low to medium | High |

| Maintenance | Needs glue tank cleanup | Minimal |

| Speed | Fast | Fast |

If you produce budget or mid-range furniture in bulk, hot melt gives a solid balance. But if your clients expect flawless edges, laser is the better fit—if you can justify the price.

Which Edge Banding Method Is Best for Your Furniture Production Line?

Still unsure which method suits you best? Let’s find the match based on your factory’s real needs.

The best edge banding method depends on your production volume, quality expectations, equipment budget, and product application. There’s no one-size-fits-all solution.

Ask These Questions Before You Decide

1. What’s Your Product Positioning?

If your brand sells to budget markets or office furniture distributors, customers may accept minor imperfections. Hot melt is often enough. If you’re targeting kitchen studios or Europe, seamless matters more.

2. How Big Is Your Operation?

Small workshops: Go with hot melt. Low investment, easy to operate.

Large-scale or export factories: Laser brings long-term efficiency.

3. Do You Have Skilled Operators?

Laser systems are automated, but setup requires training. Hot melt systems are simpler to operate but require manual glue management.

4. Do You Offer Custom Orders?

If you’re running many small batch jobs, laser helps save glue switch time and gives consistent results across different board types.

| Factory Type | Suggested Method |

| Small/local workshop | Hot melt |

| Mass production factory | Hot melt or PUR |

| Premium furniture producer | Laser edge banding |

| Exporter to EU or US | Prefer laser |

I’ve had clients start with hot melt, then scale up with laser once volume increased. You don’t have to jump all in—but you need a roadmap.

Cost Comparison: Is Laser Edge Banding Worth the Investment?

Laser edge banding sounds great—but is it worth the money?

Laser edge banding requires a higher upfront investment, but it lowers long-term maintenance costs and increases product value. Whether it’s “worth it” depends on your product margins and client expectations.

Let’s Break Down the Numbers

1. Machine Cost

Hot melt machine: $5,000–$20,000 depending on features.

Laser system: $50,000+ for full automation.

2. Operating Cost

Hot melt: Ongoing glue costs, machine cleaning, glue waste.

Laser: No glue, fewer parts to replace, but more expensive tape.

3. Labor and Downtime

Laser reduces operator workload. It also means fewer breakdowns related to glue tank issues.

4. End Product Value

If laser gives you a product you can sell for 20–30% more, the machine pays for itself much faster.

| Cost Area | Hot Melt | Laser |

| Machine Price | Low | High |

| Tape Cost | Standard | Higher (with polymer) |

| Maintenance | Regular (glue tank) | Minimal |

| Edge Quality | Moderate | Premium |

| Return on Investment | 6–12 months | 12–24 months (but higher margins) |

In my own experience helping factories switch, most recouped their laser machine investment in less than two years—just from winning bigger contracts.

Conclusion

The edge banding method you choose will shape your product quality—and your brand’s future. Pick the one that fits your business, not just your budget.