I see the problem often: customers get surprised by bad edges. They lose trust fast. I want to fix that. (PAS: Problem → Agitate → Solve)

Consistent edge banding quality matters because it reduces returns, saves time, and keeps distributors buying from the same source again and again. A reliable supply lowers risk and raises margins.

We will look at why consistency matters, what risks come from poor supply, how quality turns into trust, and how to keep quality steady. I will also explain how I (and CT Edgeband) make stability real.

Why Consistency in Edge Banding Quality Matters for Distributors?

I have seen distributors burn hours sorting bad batches. They lose business quickly. (PAS)

Consistent quality gives distributors confidence to stock larger volumes and recommend the product to clients. It lowers returns and rework.

Dive deeper: What consistency really means, and why distributors care

Distributors do not sell a single roll. They manage orders for many customers. Each customer expects the same color, thickness, adhesion, and finish across batches. If one shipment varies, the distributor faces complaints, rework, and possibly lost contracts.

Consistency covers several technical areas:

- Color and finish match. Small color shifts matter on large projects. Distributors must avoid visible mismatches between panels and edges.

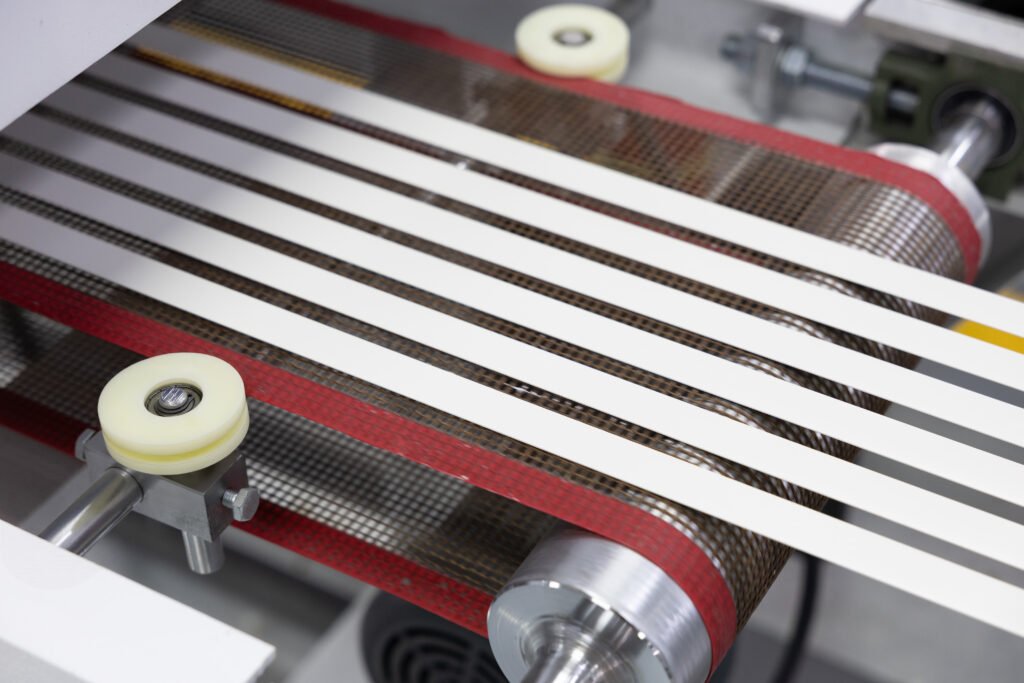

- Thickness and tolerances. Machines expect precise widths and thickness. Too thick or thin rolls cause waste and machine jams.

- Adhesive performance. Edge banding must bond reliably under the factory’s press temperatures and cycle times. Failures raise return rates. Common causes of bonding failures include wrong adhesive temperature, wrong spread amount, and insufficient pressing.

- Dimensional stability. Rolls must spool and unwind without deforming. Warped coils lead to production stops.

- Material consistency. Different materials behave differently. PVC, ABS, melamine, and veneer have distinct handling and durability traits. Knowing the material profile matters for the distributor and the end user.

I think about consistency as three connected systems: product design, production control, and testing. You need all three. If one fails, the other two cannot carry the burden. Distributors prefer suppliers who document tolerances and provide batch certificates. That documentation lowers perceived risk. When a supplier backs up quality with data, distributors will order larger quantities and choose that supplier over competitors. Market trends also matter. The global edge banding materials market is substantial and growing; companies that secure consistent quality position themselves to capture more share as the market expands.

The Hidden Risks of Inconsistent Edge Banding Supply?

I once worked with a distributor who lost a major cabinet contract after a color mismatch. They never fully recovered that client. (PAS)

Inconsistent supply creates direct costs like returns, and indirect costs like damaged reputation and lost future orders. It hurts margins more than the price difference between suppliers.

Dive deeper: Financial, operational, and reputational risks

Inconsistent edge banding shows up slowly and then suddenly. At first, you see more small claims and reworks. Over time, repeat customers drop you.

Financial risks

- Returns and rework. Each return costs materials, labor, and transport. These costs quickly exceed small savings from buying cheaper inconsistent stock.

- Contract penalties. Large jobs often have delivery and acceptance clauses. Nonconforming materials can trigger penalties.

- Inventory write-offs. Unsellable rolls become waste. Inventory that sits because of mismatch ties up cash.

Operational risks

- Line stoppages. Edge banding that jams or flakes increases downtime on panel lines.

- Increased inspection time. Distributors must test more, which raises handling costs.

- Supplier switching costs. If a distributor must switch suppliers to recover quality, there is lead time, validation, and potential MOQ (minimum order quantity) headaches.

Reputational risks

- Trust erosion. Distributors depend on trust. One visible failure spreads fast by word of mouth.

- Loss of referrals. Dealers and joiners recommend suppliers. Bad batches reduce referrals.

Hard numbers and context

Repeat customers are critical. Studies show small increases in retention drive large profit improvements. For example, Bain & Company found that increasing customer retention by 5% can raise profits substantially; other industry summaries report repeat customers spend more and cost less to serve. This means consistent quality that raises retention can be more profitable than chasing lower unit prices.

I therefore treat inconsistency like a hidden tax. It is easy to miss on a cost sheet. But it shows clearly on a distributor’s P&L after several quarters.

How Quality Consistency Strengthens Customer Trust and Repeat Business?

My best distributor relationships started after I fixed a recurring quality issue. They rewarded me with bigger orders. (PAS)

Consistent quality builds trust. Trust converts into reliable reorders, referrals, and willingness to co-develop products. Reliable suppliers enjoy lower sales costs per order.

Dive deeper: The mechanics of trust and how consistency converts into loyalty

Trust is both emotional and rational. Distributors feel trust when they see proof. Proof can be steady on-time delivery, consistent test results, and rapid corrective actions.

How consistency converts to repeat business

- Lower perceived risk. When every batch matches, buyers feel safe increasing order size.

- Faster quoting and less inspection. Distributors spend less time checking every consignment. That lowers internal labor costs.

- Better margins. Less rework and fewer returns improve margins. Distributors can pass reliability value to their clients or keep a larger margin.

- Cross-selling. Distributors who trust a supplier are more likely to test and buy adjacent products (e.g., matching profiles, adhesives, edge-processing tools).

- Long-term partnerships. When a supplier consistently delivers, both sides invest in joint forecasting, inventory management, and product development.

Evidence that retention matters

Market research and loyalty guides show that brand and product loyalty in B2B manufacturing translate into steady revenue and lower marketing spend. Companies that maintain high product reliability see better lifetime value per customer. This is not theoretical. The furniture and materials market is growing; suppliers that lock in distributor loyalty capture more of that expanding spend.

Practical steps I use to build trust

- Share batch test data proactively.

- Offer sample runs for color matching.

- Keep a visible nonconformance log and share corrective actions.

- Provide clear lead times and emergency support.

These steps lower friction. They turn transactions into partnerships.

Key Practices to Maintain Consistent Edge Banding Quality?

I think of quality like a machine: it needs settings, feeds, and checks. (PAS)

Key practices include strict incoming material inspection, process controls, and routine adhesion and color tests. Documentation is essential.

Dive deeper: Concrete controls, tests, and systems that work

Consistency depends on tools and discipline. I use the following pillars:

1. Incoming material control

- Check supplier certificates for raw film or veneer.

- Inspect color, thickness, and surface finish on arrival.

- Sample adhesive properties from each batch.

2. Process control and SOPs

- Fix setpoints for laminating temperatures, adhesive spread, and press dwell time.

- Calibrate equipment daily.

- Lock changeover checklists when switching colors or widths.

3. Testing and QA

- Adhesion tests. Run peel tests under expected press conditions. Adhesive problems are a leading cause of failure. Regular peel tests prevent surprises.

- Color measurement. Use a colorimeter for repeatable matches. Document ΔE tolerances.

- Dimensional checks. Track roll width, thickness, and spool tension.

4. Traceability

- Label each carton with batch number and production date.

- Keep test results linked to the batch number.

5. Continuous improvement

- Log nonconformances and corrective actions.

- Run root cause analysis for recurring defects.

- Share lessons with the production team and suppliers.

6. Customer-facing transparency

- Provide distributors with batch certificates.

- Offer a small buffer stock or priority replenishment for strategic partners.

- Enable sample approval flows before full production.

When a system combines prevention, detection, and transparency, consistency becomes predictable. That predictability is what distributors pay for in time and trust.

How CT Edgeband Ensures Quality Stability for Global Distributors?

I built CT Edgeband to solve the problems I saw in the market. I designed systems that reduce surprises. (PAS)

CT Edgeband focuses on documented tolerances, batch testing, and quick corrective action. We commit to consistent color, adhesive performance, and on-time delivery.

Dive deeper: Our methods, evidence, and the value we deliver

I will explain our approach in steps and show how it ties to distributor benefits.

Step 1 — Standardized specifications

We set clear product specs for color, thickness, gloss, and edge profile for each SKU. Each spec includes acceptable tolerances. Distributors get these specs before first order.

Step 2 — In-line controls and SPC

We use simple statistical process control (SPC) charts on key variables like thickness and adhesive temperature. Our staff checks these values at planned intervals. When a point drifts, we stop the line and fix it.

Step 3 — Adhesive and bonding validation

Adhesive problems are common across the industry. We run peel and shear tests that simulate client press conditions. If a batch fails, we hold the shipment and reprocess or replace it. This practice comes from industry findings that show incorrect adhesive temperature and spread are frequent causes of defects.

Step 4 — Color matching and sample approvals

We provide colorimeter readings and sample rolls for every new project. Distributors can approve samples before bulk runs. This avoids costly on-site mismatches.

Step 5 — Documentation and traceability

Every carton shows a batch number and test summary. Distributors can ask for the batch report. This transparency reduces inspection time on their side.

Step 6 — Partnership practices

We run a vendor-managed-stock option for selected partners. We also offer priority rework slots when a client has an emergency. These terms help distributors plan and win larger contracts.

Value delivered

- Less returns and rework.

- Shorter inspection cycles for distributors.

- Higher reorder rates and larger order sizes.

The market size for edge banding materials is large and growing, driven by furniture production. By focusing on consistency, I position CT Edgeband to be a reliable partner as this market grows. (IMARC Group)

Conclusion

Consistent edge banding quality reduces cost, builds trust, and creates repeat business. Good systems beat low prices every time.

Data sources and links

- IMARC Group — Edge Banding Materials Market Report (market size and regional insights). (IMARC Group)

https://www.imarcgroup.com/edge-banding-materials-market - Jowat — Failures in Edgebanding: causes and solutions (adhesive and process causes). (乔瓦特)

https://www.jowat.com/en-US/newsroom/detail/failures-in-edgebanding-the-most-frequent-causes-and-how-to-solve-them/ - Bioresources / NC State — Research on edge banding materials and effects (material behavior). (BioResources)

https://bioresources.cnr.ncsu.edu/resources/effect-of-edge-banding-thickness-dowels-and-adhesive-types-on-withdrawal-strength-in-oriented-strand-board/ - Industry summaries on customer retention and B2B loyalty (Bain & related summaries). (IndustrySelect)

Example: IndustrySelect summary referencing Bain research — https://www.industryselect.com/blog/14-surprising-customer-retention-statistics - Market overviews and forecasts (supporting growth context for edge banding materials). (Coherent Market Insights)

Examples: Coherent Market Insights and Cognitive Market Research.