I face common edge problems every week: peeling, mismatched color, or weak bonds. I know readers want clear fixes fast.

PVC edgeband bonds well to most manufactured boards, but substrate density, porosity, moisture behavior and glue choice change the result. I explain how to match materials and methods for long-lasting edges.

I’ll walk you from the basics to practical fixes. I keep steps short and clear. Read on if you want fewer callbacks for repairs and cleaner production runs.

How Different Wood Substrates Affect the Bonding Performance of PVC Edgeband?

I used to blame the edgeband when peeling happened. Then I learned to test the board first.

Different boards absorb adhesive differently. That affects bond strength and edge finish. Knowing board traits helps me pick glue and settings.

Dive deeper

Key substrate traits I check

- Density & porosity. MDF is dense and uniform. Particleboard has larger particles and is more porous. Plywood is layered and less uniform across thickness. These traits affect how adhesive wets and penetrates the edge.

- Moisture behavior. Plywood resists moisture better. MDF and particleboard swell more if exposed. Swelling creates stress at the bond line and can cause lifting.

- Edge quality after cutting. MDF gives a smooth cut. Particleboard can show voids. Plywood shows layers and voids where glue can pool or starve. The cut surface dictates prep work.

Practical checks before edgebanding

- Tap test for density feel. I knock or weigh small samples. It’s quick and tells me if the board is consistent.

- Look for voids. I run a knife along the cut edge. Big voids need filler or a different approach.

- Measure moisture content. If it’s over recommended values, I dry or reject the panel.

Short table: How traits affect bonding

| Trait | MDF | Plywood | Particleboard |

|---|---|---|---|

| Density uniformity | High | Medium | Low |

| Edge smoothness after cut | Very smooth | Layered | Rough, voids |

| Moisture resistance | Low | High | Low |

| Typical adhesive penetration | Low (surface wetting) | Variable | Higher into pores |

What I do differently for each board

- MDF: Use moderate-temperature hot-melt. Keep glue flow even. Minimal prefill required.

- Plywood: Watch for gaps. Use slightly more open time or a primer. For high-grade plywood I sometimes use PUR for water resistance.

- Particleboard: Fill large voids or use a different edge profile. Increase glue to ensure mechanical anchoring.

I learned these by trial and by reading adhesive guides. Small prep steps save hours of rework.

Comparing MDF, Plywood, and Particleboard: Which Substrate Works Best with PVC Edgebanding?

When I choose a substrate, I balance cost, look and long-term performance.

For clean finishes and low maintenance, plywood often wins. For paint-ready surfaces, MDF is best. For low cost, particleboard works but needs careful prep.

Dive deeper

Performance summary

- Plywood: Best for structural strength and moisture resistance. It holds fasteners and tolerates wear. For edgebanding, plywood edges can show ply gaps that need sanding or filling. I pick plywood when long life and moisture exposure matter.

- MDF: Best for paint and veneering. It offers a flat, uniform face which makes color match easier. But MDF swells when wet. That means in kitchens or bathrooms I avoid exposed MDF edges unless sealed properly.

- Particleboard: Budget-friendly and common in mass furniture. It needs clean edges and often pre-filling to avoid blistering or poor bond. I use particleboard when cost is critical and the product will be indoors in stable humidity.

Cost vs performance table

| Factor | Plywood | MDF | Particleboard |

|---|---|---|---|

| Material cost | High | Medium | Low |

| Finish quality for edgeband | High | High (painted look) | Medium |

| Durability in humidity | High | Low | Low |

| Prep needed for edgeband | Medium | Low | High |

How I decide in practice

I ask three questions:

- Where will the product be used? (high humidity gets plywood)

- Is paint or veneer the main finish? (painted = MDF)

- What is the budget and expected life? (low budget + indoor use = particleboard)

I pick materials to match the end use. That reduces warranty returns.

Key Factors That Influence PVC Edgeband Adhesion on MDF, Plywood, and Particleboard?

I once ran a full batch that failed because of one setting. I now check five things every time.

Adhesive type, temperature, surface prep, panel moisture and edge porosity are the key factors. Small changes here change bond strength a lot.

Dive deeper

The five factors I verify

- Adhesive chemistry. EVA, PA, and PU (PUR) hot melts act differently. PUR crosslinks with moisture and gives stronger, more water-resistant bonds. EVA is common and cheaper. Choose based on use-case.

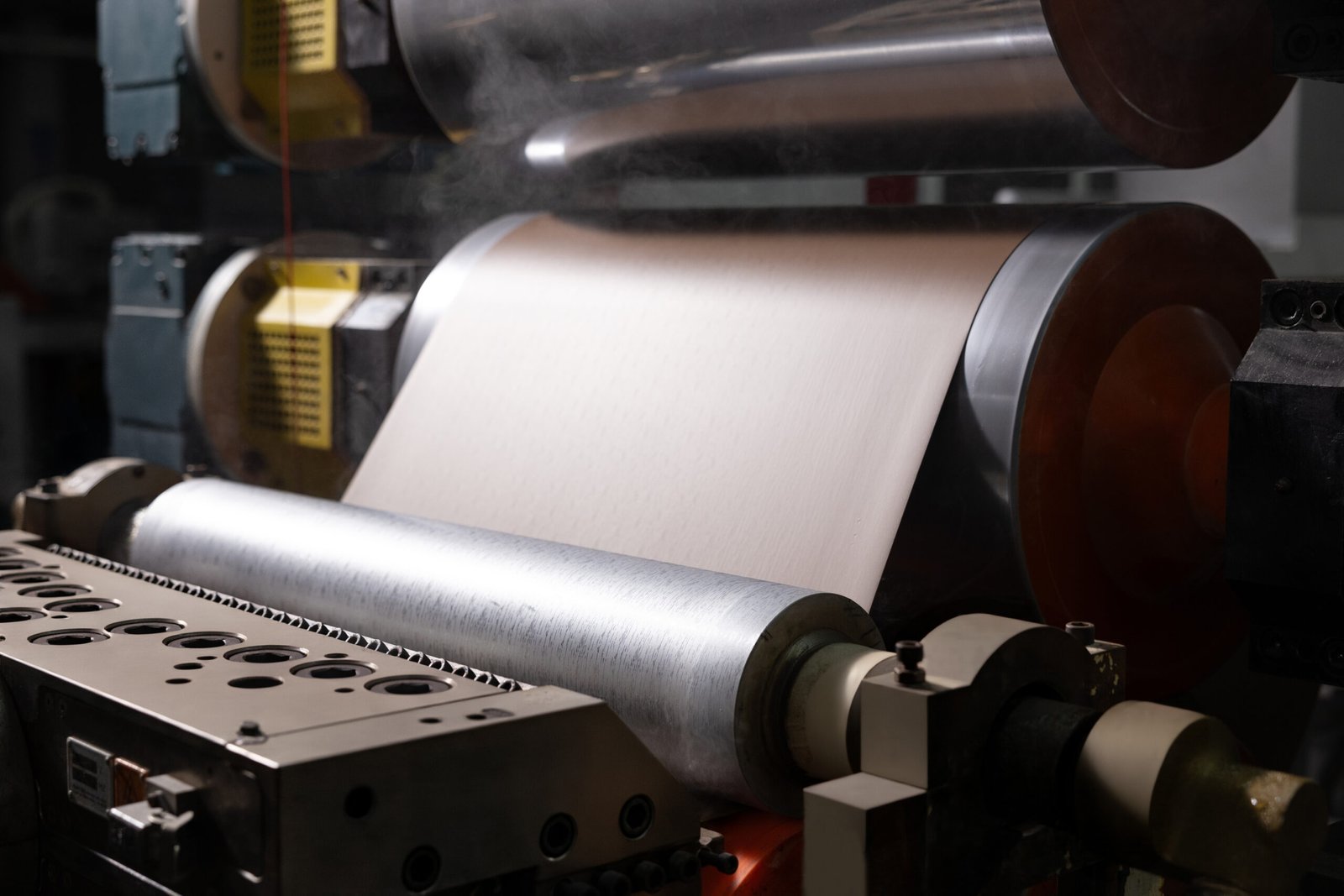

- Glue temperature and open time. Too hot can melt PVC edges or cause bubbling. Too cool gives weak joints. I follow glue maker specs and tune machine speed.

- Panel moisture content. High moisture reduces bond and can cause blisters later. I aim for panel moisture within recommended range. If panels are damp, I dry them first.

- Edge porosity and voids. Voids let glue pool or thin. For particleboard I fill large voids or use a different banding method.

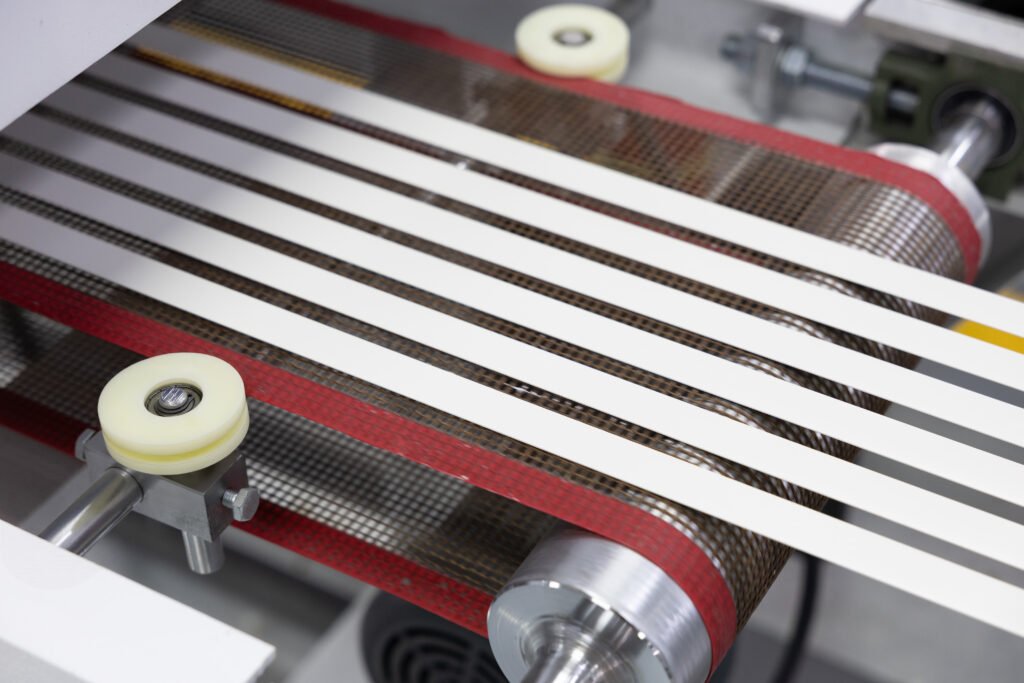

- Machine pressure and speed. Pressure must press the band into glue without squeezing glue out. Speed must match open time. I run small tests when I change boards.

Troubleshooting checklist I use on the shop floor

- Run a 1-meter test and peel at 90° to check bond.

- Check cut edges under magnifier for voids.

- Adjust glue temperature +/- 5°C and retest.

- Swap from EVA to PUR if moisture resistance is required.

Short technical note on adhesives

PUR adhesives provide chemical cross-linking and superior water and heat resistance. They are more expensive but reduce delamination risk in demanding environments. EVA and polyolefin adhesives are reliable for many indoor uses.

Common Compatibility Issues Between PVC Edgeband and Wood-Based Panels—and How to Solve Them?

I used to get calls about bubbling and color mismatch. Most were solvable without remaking the furniture.

Common issues are peeling, bubbling, color mismatch and edge waviness. Fixes include correct glue, edge prep, temperature control and storage handling.

Dive deeper

Peeling and delamination

- Causes: Poor adhesion due to wrong glue, cold glue, dirty edge, or high substrate moisture. Cross-grain stress in plywood can also pull the edge loose.

- Fixes I use: Reheat and press for small areas. For larger failures, remove band, clean, reapply with correct adhesive and settings. Use PUR for higher durability.

Bubbling or blistering

- Causes: Trapped moisture or volatile gases in the panel, overheated glue that vaporizes, or uneven heating. Some particleboard cores release trapped air under heat.

- Fixes I use: Lower glue temp slightly. Slow machine speed to allow gases to escape. Pre-dry panels if necessary.

Color and texture mismatch

- Causes: Different dye lots or substrate color showing under thin edges. Light changes also reveal small color shifts.

- Fixes I use: Order enough edgeband from same dye lot. Keep samples and do mockups before mass runs.

Mechanical problems: edge waviness or raised corners

- Causes: Incorrect pressure or too much glue. Uneven edges cause gaps.

- Fixes I use: Adjust pressure rollers. Sand the edge flat or use a filler profile before banding.

Quality assurance steps I require

- Always test a 1–2 m piece before a full run.

- Keep a record of glue batch, temperature, and machine speed for every job.

- Train operators to spot edge voids and moisture signs early.

Best Practices to Improve PVC Edgeband Application Across Various Furniture Substrates?

I aim to cut rework by half with a short checklist. These steps help.

Prep, correct adhesive, controlled environment, and trial runs cut failures. Standardize settings per substrate and keep records.

Dive deeper

My step-by-step shop routine

- Material intake: I inspect boards for moisture, density changes, and visible voids. I reject or quarantine poor panels.

- Cutting & edge prep: I use sharp blades and a backing support. I sand or fill large voids on particleboard. For plywood, I route to reduce layer gaps.

- Adhesive selection: I match glue to substrate and end use. For kitchen cabinets I prefer PUR. For indoor shelving EVA works well.

- Machine setup: I set glue temperature per adhesive spec. I test pressure and speed on sample pieces. I document the settings.

- Post-process checks: I trim, scrape, and buff. I do a peel test and visual inspection. I store finished parts flat and dry.

Production tips that save time and money

- Standardize recipes. Create a settings sheet for MDF, plywood and particleboard. Operators use the correct recipe every time.

- Stock control. Use same edgeband dye lot for a project. Label rolls with batch info.

- Training. Short daily training helps the team spot issues early. I run a 10-minute demo when I change materials.

My quick troubleshooting flow

- If peeling occurs: check glue, temp, and moisture.

- If bubbling occurs: lower heat and dry panels.

- If color shift occurs: check edgeband batch and lighting.

These habits cut returns and boost customer trust.

Conclusion

Match substrate traits with the right glue, prep, and settings to get clean, durable PVC edges.

Data sources and links

- MrsWoodcraft — Particle Board vs Plywood vs MDF: Differences & Prices. https://mrswoodcraft.com/blog/particle-board-vs-mdf-vs-plywood. (mrswoodcraft.com)

- Lowe’s — Particle Board Buying Guide. https://www.lowes.com/n/buying-guide/particle-board-buying-guide. (Lowe’s)

- TAKA Adhesives — Edge Banding Adhesives (PUR explanation). https://taka-adhesives.com/product-category/polyurethane-hot-melt-adhesives-hmpur/wood-adhesives/edgebanding-adhesives/. (TAKA)

- ScienceDirect — Edge Delamination overview (causes and mechanics). https://www.sciencedirect.com/topics/engineering/edge-delamination.

- Bondrite / Edge Banding adhesives product info — bonding PVC to wood-based panels. https://bondrite.co.uk/product/edge-banding-hot-melt-adhesive-h1300/. (Bondrite Adhesives)