Problem: Color mismatch ruins a run and leads to returns.

Agitation: Small shifts cost time and money.

Solution: I show how factories keep colors steady, step by step.

Working with a manufacturer means they use strict recipes, inline spectrophotometers, controlled environments, and master samples. These actions cut visible color shifts and lower scrap.

I write from hands-on work with suppliers. I will share practical checks and data you can ask for. Keep reading and you will know what to require from your edgeband partner.

How Manufacturers Control Raw Material Formulas to Prevent Color Shifts?

Problem: Raw materials vary by lot and change finished color.

Agitation: A small resin or pigment change becomes a visible mismatch.

Solution: Factories control formulas and batches.

Manufacturers lock formulations. They record masterbatch lots, pigment recipes, and additive levels. They track supplier lot numbers. They test incoming masterbatch and film before use. When a resin lot changes, they run a small trial batch to compare Delta E against the master. These steps stop surprises before full production.

Dive deeper

Recipe control and traceability

I always ask for the formula sheet. It shows pigment ratios, stabilizers, and processing aids. The factory should keep that sheet with a lot number. If a supplier sends a new masterbatch lot, the factory compares it to the master recipe first.

Incoming material checks

Good factories test every delivery. They use a lab spectrophotometer or colorimeter to read the sample. They compare the readout to the target using Delta E standards. If the Delta E is outside tolerance, they quarantine the lot.

Masterbatch and carrier film

Two big sources of variation are masterbatch and decorative film. Factories buy masterbatch from trusted suppliers. They ask for certificates of analysis. They also test decorative film from the laminate supplier for color and sheen. When either supplier changes a pigment or backing, the factory records it and re-tests.

| Control point | Action | Why it matters |

|---|---|---|

| Masterbatch lot | Lab test & lot trace | Prevent batch-to-batch pigment shifts |

| Decorative film | Color and sheen test | Avoid metamerism with substrate |

| Additives | Documented recipe | Stabilizers affect color under heat |

I once saw a plant stop a full run because a new masterbatch had a slightly different blue. The cost of a short delay was far less than rework. That is the logic behind strict raw-material control.

Why Digital Color Matching Systems Reduce Variations Between Production Runs?

Problem: Visual matching is subjective and inconsistent.

Agitation: Human sight can’t catch subtle drift.

Solution: Digital systems measure color and automate corrections.

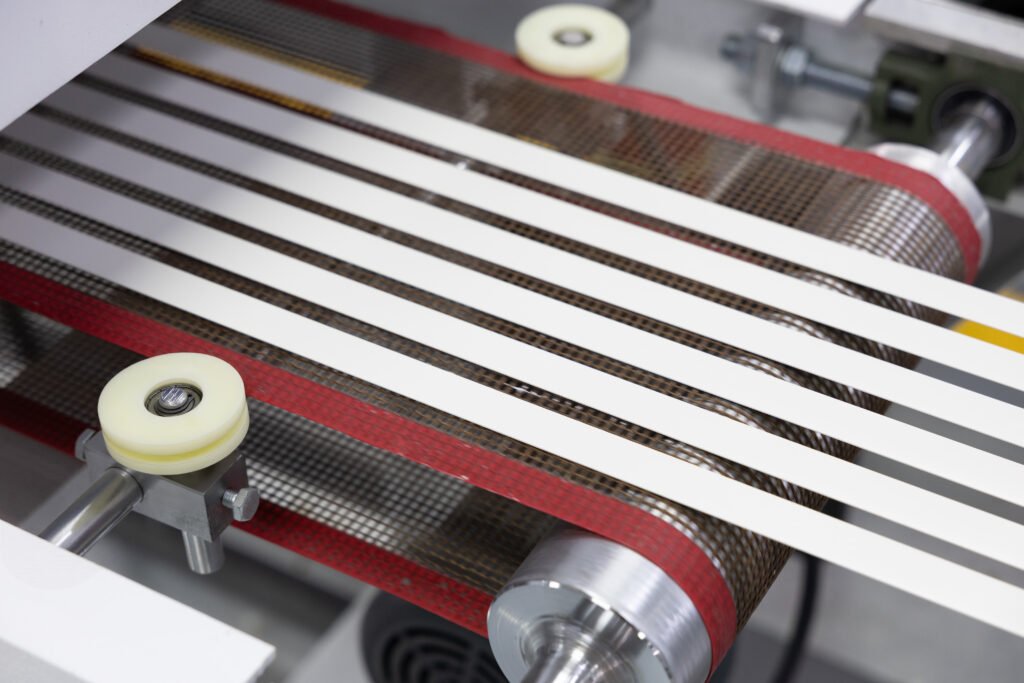

Inline spectrophotometers and color control software give real-time color data. They measure Lab* values and calculate Delta E. Some systems connect to masterbatch feeders. They adjust dosing automatically when the color drifts. This creates a closed loop that reduces waste.

Dive deeper

What the system does on the line

An inline spectrophotometer reads the extruded edgeband as it runs. The system compares the read to the target. If the difference exceeds the set Delta E, the controller changes masterbatch dosing or alerts the operator. Some systems operate continuously. Others sample at set intervals.

Delta E and tolerance

Delta E gives a single number for color difference. Most manufacturers use CIEDE2000 (∆E00) because it matches human perception better. Tolerances depend on the product. For edgeband, factories often aim for ∆E ≤ 1 to 2 for critical color matches, and looser values for secondary colors. You can ask your supplier what standard they use.

Closed-loop correction

Systems like SpectroMetric link the spectrophotometer to a masterbatch feeder. When color shifts, the feeder changes dosing in real time. That reduces the need for manual stops and rework. It also lowers scrap by keeping the output inside tolerance.

| Feature | Benefit | What to request |

|---|---|---|

| Inline spectrophotometer | Real-time measurement | Proof of inline readings |

| Closed-loop feeder | Automatic correction | Data logs of adjustments |

| Color QC software | Historical trend view | Exportable trend charts |

I prefer suppliers who can provide trend charts. Those charts show how stable a run was. They also prove the factory can hit your tolerance consistently.

How Inline Quality Checks Catch Early Color Drift During Extrusion?

Problem: Color drift starts small and grows fast.

Agitation: Late detection leads to large sections out of tolerance.

Solution: Inline checks detect drift early and keep runs tight.

Inline checks combine sensors, cameras, and lab verifications. They spot thickness variation, surface sheen, and color shift. This early detection stops bad runs fast. I look for facilities that log every check and keep samples for each production lot.

Dive deeper

Types of inline checks

- Spectral color readings. These give Lab* and Delta E numbers.

- Camera-based visual checks. These catch streaks, lines, and surface defects.

- Dimensional gauges. Width and thickness control affect perceived color when light reflects.

- Adhesion and peel tests. Poor bonding can change the edge’s final look.

Sampling and retention

A best practice is to retain physical samples from each lot. The sample sits with a record of the spectrophotometer read. If a customer reports an issue later, the factory can re-check the retained sample and trace the problem.

Statistical process control (SPC)

Factories use SPC to understand process variation. They set control limits. When a measurement leaves those limits, the line pauses and the team investigates. This method reduces repeat defects and improves consistency over time.

| Check type | Frequency | Purpose |

|---|---|---|

| Spectrophotometer read | Continuous or every few minutes | Maintain color target |

| Camera scan | Continuous | Detect visual defects |

| Dimensional gauge | Continuous | Keep reflectance consistent |

| Physical sample | Per lot | Traceability and dispute resolution |

I insist on visible SPC charts. They show process drift before the product fails. Inline checks save time and money because they stop error accumulation.

How Environmental Conditions in the Factory Affect Color Stability?

Problem: Temperature and humidity change how pigments behave.

Agitation: The same recipe looks different on two days.

Solution: Control the factory environment and processing temperatures.

PVC and its additives react to heat. High melt temperature can darken the compound. Humidity can affect plasticizer distribution. Factories control extrusion temperatures, cooling rates, and workshop humidity. They use conditioned storage for films and masterbatches. This control reduces unplanned color shifts.

Dive deeper

Temperature control in extrusion

Extrusion heat affects color. If the melt gets too hot, PVC can degrade and brown. The factory sets fixed temperature profiles for each formula. They log the actual temperatures during each run. If a profile drifts, they stop and correct it.

Humidity and storage

Decorative film and masterbatch can absorb moisture or change with humidity. Factories store them in conditioned rooms. They avoid long exposure to high humidity. That keeps pigments stable and avoids processing defects.

Cooling and take-off speed

Cooling rate affects surface appearance and gloss. The speed of take-off and chill roll temperature change how the film and edge solidify. Factories standardize these parameters for each product type.

| Environmental factor | Control measure | Effect on color |

|---|---|---|

| Melt temperature | Fixed profile & logs | Prevents browning |

| Ambient humidity | Conditioned storage | Keeps pigment behavior steady |

| Cooling rate | Set chill roll temp | Controls gloss and reflectance |

I always ask suppliers for their processing profiles. If they will share logs, I review them. That gives me confidence that the same settings will be used for repeat orders.

Why Standardized Master Samples and Batch Records Ensure Repeatable Color Results?

Problem: Without a clear target, every run is subjective.

Agitation: Customers reject parts that “look wrong.”

Solution: Use master samples and rigorous batch records.

A master sample is the gold standard. Factories keep a physical sample under controlled light. They also store the spectrophotometer target data. Each production lot gets a batch record that ties the physical sample, the instrument read, and the material lots together. This practice makes color repeatable and traceable.

Dive deeper

Master samples and light booths

Master samples live in a light booth under standard illuminants (D50, for example). The booth shows how the sample looks under consistent light. Factories photo-document the sample and store its spectrophotometer profile.

Batch records and traceability

A batch record links: the formula, masterbatch lot, film lot, process profile, and QC reads. When a customer files a complaint, the factory pulls the lot’s record and retests the retained sample. This traceability speeds root-cause analysis.

Customer acceptance criteria

We set acceptance criteria up front. We agree on a Delta E tolerance and the light booth standard. We also agree on where the readings are taken on the profile. These clear rules avoid later arguments.

| Document | Contents | Use |

|---|---|---|

| Master sample | Physical sample + spectro data | Target for all future runs |

| Batch record | Material lots + process log | Traceability and root cause |

| Acceptance report | Delta E values + photos | Customer sign-off |

I insist on a signed acceptance report for new or critical colors. That locks the target in place for future repeats.

Conclusion

Color consistency is a system. I rely on formula control, digital measurement, inline checks, stable environments, and strict records to keep edgeband color repeatable.

Data sources & links

- X-Rite — Monitor and Control the Color of Plastic Film (inline spectrophotometers).

https://www.xrite.com/learning-color-education/using-our-solutions/plastic-inline. (xrite.com) - Ampacet — SpectroMetric in-line continuous color correction system.

https://www.ampacet.com/introducing-spectro-4-0-qc-solutions-innovative-in-line-continuous-color-management-systems/. (ampacet.com) - Datacolor — Best practices for Delta E tolerances.

https://www.datacolor.com/business-solutions/blog/best-practices-delta-e-tolerances/. (Datacolor) - Sharc Processing & Machinery — PVC extrusion: key factors affecting process and thermal sensitivity.

https://www.sharcpm.com/news/pvc-extrusion-key-factors-affecting-compound-extruder-process/. (SHARC) - HunterLab — In-line and in-process spectrophotometers for production.

https://www.hunterlab.com/en/products/in-line-in-process-spectrophotometers/. (hunterlab.com)