I once partnered with the wrong edge banding supplier. It cost me time, money, and trust from customers.

Before you sign a deal, you must know how to evaluate a wholesale edge banding supplier based on real business criteria, not just price or brochure talk.

Choosing the right supplier is one of the hardest decisions you’ll make as a distributor. A bad choice can lead to inconsistent quality, late deliveries, and lost profit. If you learn what criteria matter, you can protect your business and build a stable supply chain.

What Really Makes a Wholesale Edge Banding Supplier Reliable in the First Place?

I remember when I first looked for a supplier. I focused on low price and ignored checks on history and systems. That was a mistake.

A reliable wholesale edge banding supplier has proven systems for quality, delivery, compliance, and responsiveness that match your business needs.

Key Reliability Factors

Here are the core things you must check before partnering:

Quality Assurance Systems

- Does the supplier have a quality management system such as ISO 9001?

- Can they show documented QC processes, inspection reports, and test results?

- Have they worked with similar customers and met quality expectations before?

Suppliers with clear QC documentation tend to have fewer defects and more consistent output.

Delivery Reliability

- Can they deliver on time and handle fluctuations in demand?

- Do they have a record of meeting delivery schedules?

- How do they handle delays or backorders?

Reliable delivery is a major part of supplier trust. If they cannot ship on time, your inventory and production will stall.

Compliance and Responsibility

- Are they compliant with legal and export regulations?

- Do they follow labor and safety laws?

- Is there any record of sanctions or penalties against them?

Legal and ethical compliance protects your business from risk.

In short, reliability means they can meet your expectations for quality and delivery, and they do it in a stable, documented way. Suppliers with strong systems behind their operations are easier to work with in the long run.

How to Check a Supplier’s Manufacturing Capacity, Quality Control, and Consistency?

When I started scaling my orders, I realized factory capabilities matter more than sales talk.

Manufacturing capacity, quality control processes, and consistency tell you whether a supplier can meet your current and future demands without breakdowns.

Evaluating Capacity

You need to know how much the supplier can produce and maintain:

- Ask about current production volume and load.

- Check equipment types, staff count, and shifts per day.

- Look for plans on how they handle peak demand or rush orders.

A supplier might have marketing claims, but real capacity is how quickly they can deliver regular and large orders reliably.

Quality Control Practices

A good supplier has structured quality checks at every step:

Pre‑Production

- Do they test raw materials before production?

- Are incoming materials inspected against spec?

In‑Process Inspection

- Are there checks at defined production stages?

- Do they record defect rates?

Final Audit

- Is each batch tested before shipment?

- Can they provide batch traceability and inspection certificates?

These practices help you avoid surprises such as batch variation or hidden defects.

Consistency of Outputs

Consistency means delivering the same quality every time:

| Metric | What to Check | Why It Matters |

|---|---|---|

| Defect Rate | % defective products per order | Lower is better |

| Lot to Lot Variance | Differences across batches | Stable customers want consistency |

| Repeat Orders | How many clients reorder | High reorder often means satisfaction |

| Stable suppliers track these metrics and share them with you. Stability in output quality reduces returns and wasted labor. |

What to Look for in a Supplier’s Pricing Structure, MOQs, and Cost Transparency?

Price is the obvious factor, but many businesses get hurt by hidden costs.

A good wholesale supplier’s pricing structure should be clear, scalable, and tied to real production economics, not arbitrary markups.

Pricing Structure

Ask:

- How does price change with volume?

- What are the discount tiers for larger orders?

- Are there fees for packaging, inspection, or documentation?

A transparent price list prevents surprises and lets you plan margins better.

Minimum Order Quantities (MOQs)

MOQs matter because:

- Too high MOQs tie up capital in inventory.

- Too low MOQs may mean higher costs per unit.

You should find a balance where you can order in batches that match your sales cycles without excess stock.

Cost Transparency

Cost transparency means:

- The supplier shows what costs are included in the price.

- There are no hidden fees for packaging or handling.

- Payment terms and logistics costs are spelled out clearly.

Transparent terms make budgeting easier and avoid unexpected charges.

How to Evaluate Color Matching, Sample Support, and Custom Edge Banding Capability?

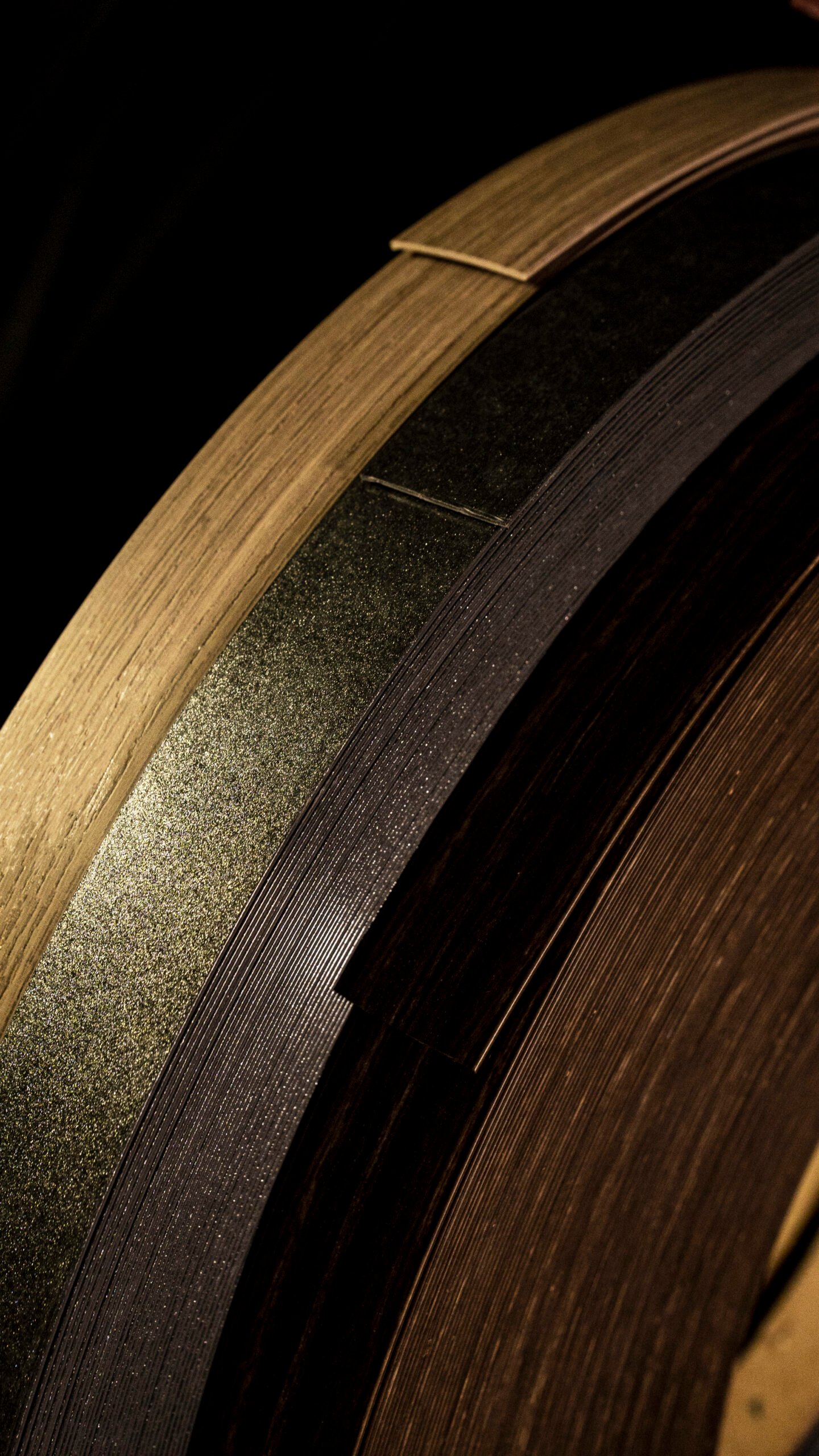

Edge banding has unique needs that go beyond basic parts. Color and fit matter.

Before you partner, you must confirm whether a supplier can meet your product detail requirements, including color matching and custom orders.

Color Matching

Edge banding often must match specific board colors:

- Ask for physical samples, not just photos.

- Compare sample batches for color shifts under real lighting.

- Check if they can match custom colors using your codes.

Good suppliers use standardized color systems and measure differences with objective tools.

Sample Support

A strong supplier will:

- Provide samples before bulk orders.

- Let you test performance and fit in your own production line.

- Support trial runs with small batches so you can validate specs.

Custom Manufacturing Capability

Custom edge banding means:

| Capability | Why It Matters |

|---|---|

| Custom width options | Matches client’s exact needs |

| Special adhesive types | Improves end performance |

| Pattern or texture options | Adds product differentiation |

| If a supplier cannot produce to your exact spec, you risk customer dissatisfaction and returns. |

When a Wholesale Edge Banding Supplier Is a Long-Term Partner Instead of Just a Vendor?

At first, I thought a supplier was just a vendor. Later I learned the difference.

A partner goes beyond transactions. A partner shares planning, invests in shared success, and supports you during changing market conditions.

Indicators of a True Partner

- They agree to long‑term pricing stability.

- They offer flexible payment terms like net‑60 / net‑90.

- They share market insights that help plan inventory.

- They support co‑development or customization projects.

True partners help you scale, not just fill orders.

Strategic Value Beyond Price

A partner helps you refine your processes:

| Strategic Support | What It Means |

|---|---|

| Forecasting support | Align inventory with sales |

| Shared planning cycles | Reduce sudden shortages |

| Risk sharing | Better handling of raw material volatility |

Working with a partner means you think together, not just buy and sell.

Conclusion

Choosing the right wholesale edge banding supplier ensures lower costs, stable quality, and reliable delivery for long-term success.

Data Sources:

Supplier evaluation best practices — Fictiv “Five Key Factors to Consider When Performing a Supplier Evaluation” https://www.fictiv.com/articles/five-key-factors-to-consider-when-performing-a-supplier-evaluation Fictiv

Comprehensive supplier criteria — CADDi “Supplier Evaluation – How It Works and Why It’s Important” https://us.caddi.com/resources/insights/supplier-evaluation CADDi

Quality and batch control insights — Alibaba “How to Source and Evaluate Suppliers in Global Manufacturing Hubs” https://www.alibaba.com/price-comparison/china-supply-chain-dominance Alibaba

General supplier evaluation criteria overview — Vaia “Supplier Evaluation Criteria” https://www.vaia.com/en-us/explanations/business-studies/operational-management/supplier-evaluation vaia.com