I lost money once because a shipment arrived late and mismatched. I learned to control sourcing, QC, and shipping. (PAS)

You can import PVC edgeband reliably if you follow a clear process: find vetted factories, test samples, control production, inspect before shipment, and handle customs correctly. This guide gives the exact steps I use.

Read on. I break the process into simple actions you can copy. I add checklists, sample forms, and where to watch for risk.

Why Importing PVC Edgeband from China Is a Smart Move for Distributors?

I once switched to a low-cost supplier and then switched back. The right Chinese partners give price, range, and speed if you manage them. (PAS)

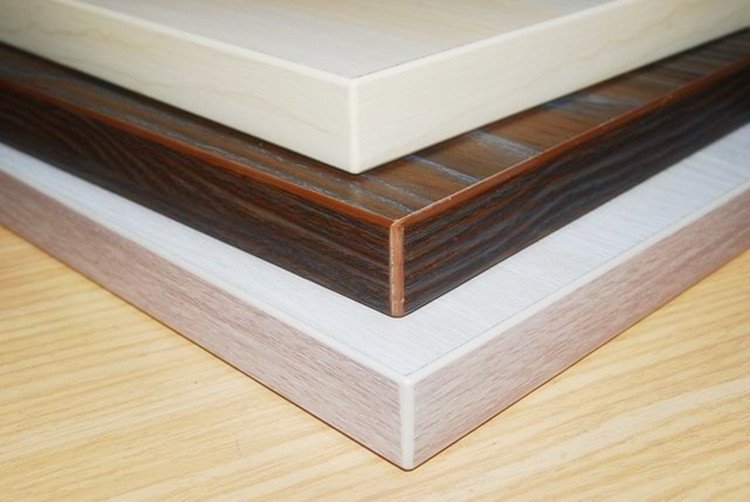

China still offers a large selection of PVC edgeband, competitive costs, and fast capacity for custom runs. With the right checks, the economics and product variety make importing worth it.

Dive deeper: market logic, cost points, and what I look for in suppliers

I import because Chinese mills cover the whole value chain. They extrude PVC, print woodgrains, offer embossing, and produce different widths and thicknesses. That vertical supply cuts lead time for custom colors and textured runs. I look for suppliers that can provide COAs, sample proofing, and lot traceability. These three items protect me in quality disputes.

Cost advantage is real, but it is not the only factor. I measure landed cost, not factory price. Landed cost includes product, QC, freight, duties, and possible rework. Ocean freight and tariffs fluctuate, so I track typical transit times and costs to set reorder points. Recent guides show sea transit times around 20–40 days and recommend planning for variability.

Speed and SKU range are key. If a mill can run small pilot lots, I can sell custom options and charge premiums. I balance stock vs. custom: keep fast-moving decors in local hubs and order custom or slow SKUs on demand. That approach keeps cash working and reduces the risk of obsolete inventory.

Before I commit, I ask for references and photos of similar work. Good suppliers welcome plant visits or third-party inspections. I budget for a first-audit or hire an inspection agent for the kickoff order.

Step 1: Research Reliable PVC Edgeband Manufacturers and Verify Their Credentials?

I once trusted a glossy website. The factory could not produce consistent color. I changed my vetting process after that. (PAS)

You must verify factory capacity, quality systems, sample practice, and export experience. Don’t rely only on Alibaba listings. I use a combination of supplier websites, trade guides, and third-party checks.

Dive deeper: how I vet suppliers step-by-step and a due-diligence checklist

Start with a shortlist. Use trade directories, industry guides, and recommended lists from other distributors. Then do a quick screen:

- Website & product range. Do they publish technical specs, embossing options, and printable samples? A robust site is a good sign but not proof.

- Certs & documents. Ask for ISO, internal QC process, and test reports (color, flexibility, UV resistance). Suppliers who run QC will share COAs and test methods.

- References & samples. Request client references and actual assembled samples (edge applied to board). Never accept flat tape photos only. Real proof reveals texture and sheen matches.

- Factory info. Ask for production capacity, extrusion lines, and embossing capability. Can they do short runs? What are MOQs? Good mills show capacity numbers.

- Export experience. Check if they ship to your region and handle required export docs. Experienced exporters save time at customs. Trade.gov country guides note common documents like commercial invoice, packing list, and bill of lading.

I also use third-party inspections for the first order. An inspector verifies batch color consistency, edge width, thickness, roll winding, and packaging. The inspector sends a photo report and sometimes a short video of the production line. That evidence reduces surprises.

Document everything. Save emails, sample photos, and test results to a supplier file. That file helps resolve disputes later.

Step 2: Request Samples, Compare Quality, and Negotiate the Right Terms?

I learned to pay for a proper sample run. Free peel-off tape photos never convinced designers. (PAS)

Ask for assembled proofs, not just raw rolls. Measure color (ΔE), gloss (GU), and confirm texture. Use sample results to set tolerances and pricing.

Dive deeper: what to request, how I test samples, and negotiation levers

What I request

- Physical edge sample roll plus at least one assembled proof on the target board.

- Lab readings if possible (Lab* and ΔE); or a promise to measure together on approval.

- Technical data: thickness, width tolerances, coil length, printing resolution, embossing depth, flame retardancy (if needed), and packaging specs.

How I test

I view the assembled proof under standard D65 lighting and the client’s intended lighting. I measure color using a spectrophotometer and record CIE Lab* values and ΔE (CIEDE2000). I also measure gloss units at 60° for moderate levels and 20° for very high gloss. Texture I document with photos and a short tactile note. These measures become the approval passport for the SKU.

Negotiation points

- MOQ and pricing tiers. Ask for breakpoints that let you buy small pilots cheaply.

- Lead time guarantees and penalties for delays on core SKUs.

- Quality clauses: require COA, assembled sample sign-off, and a remedy plan for out-of-spec batches.

- Packaging and labeling. Good packaging reduces damage and simplifies customs checks.

I price samples into the project and use them to set clear acceptance criteria. If a supplier resists assembled proofs, I treat that as a red flag.

Step 3: Manage Production, Quality Control, and Packaging Before Shipment?

I once received a container where every roll used a different core width. The client rejected 30% of the order. I never let that happen again. (PAS)

You must control production with clear specs, in-process checks, and a final inspection that includes assembled proofs and packaging confirmation.

Dive deeper: production checkpoints, inspection checklist, and packaging best practices

Production checkpoints I require

- Pre-production sample sign-off. Supplier must produce a pilot run and get my written approval.

- In-line checks. Supplier reports color readings, roll tension, embossing consistency, and weld quality at set intervals (e.g., every 2 hours). I ask for photo evidence.

- Final inspection. A 100% visual check for obvious defects on critical SKUs. For full containers, I use AQL sampling plus assembled proof checks. Third-party inspectors can do this and issue a report including measurements and photos.

Inspection checklist (sample)

| Item | Acceptable criteria |

|---|---|

| Color ΔE | ≤ chosen tolerance (e.g., ΔE00 ≤ 2 for premium) |

| Gloss GU | ± specified GU at 60° or 20° |

| Width / thickness | Within supplier tolerance ±0.1 mm |

| Embossing | Consistent depth across rolls |

| Winding | No loose edges, even rolls |

| Labeling | SKU, lot number, length on each roll |

Packaging best practices

- Use inner tubes or cores that fit machines at destination.

- Protect rolls with kraft paper and pallet wrap.

- Mark pallets with SKU, batch, and handling instructions.

- For export, pack to withstand 30–40 day transit and forklift moves.

I insist on lot traceability. Each roll gets a lot number linked to the production report. If a problem occurs later, I can trace back quickly.

Step 4: Handle Shipping, Customs Clearance, and After-Sales Coordination?

A wrong HS code once delayed customs and added fees. I now validate HS codes and prepare documents early. (PAS)

Arrange freight (FCL or LCL), prepare ISF and export docs, and work with a freight forwarder who knows PVC products. After arrival, run a quick QA and handle claims fast.

Dive deeper: logistics choices, required documents, and post-arrival steps

Freight choice

- FCL (full container) is cheapest per meter for large volumes.

- LCL (less than container) suits small runs but can add handling time and damage risk. Recent guides show LCL costs useful for small shipments but recommend extra packing. Sea transit typically runs 20–40 days; air is faster but costly.

Documents to prepare

- Commercial invoice and packing list.

- Bill of lading (ocean) or AWB (air).

- Certificate of origin if claiming preferential tariffs.

- Any requested test reports or COAs.

- Importer Security Filing (ISF) for U.S. imports and local equivalents. Trade.gov lists common required documents and cautions to prepare product-specific certificates when needed.

Customs & HS code

Use the correct HS code for PVC edge banding. A wrong code can trigger holds, extra duties, or inspections. Confirm the code with your customs broker and the supplier. Many edgebanding guides list common codes as a starting point, but you must verify locally.

On arrival

- Receive and immediately inspect a sample pallet for color, gloss, and physical damage.

- If issues appear, photograph and quarantine the batch. Notify supplier and forwarder immediately.

- Use the inspection report to file claims quickly. Time windows for freight claims are short.

After-sales

Keep a sample passport and lot numbers. Offer clients proof-of-match photos and Lab/GU numbers. That improves trust and reduces complaints.

Conclusion

I import PVC edgeband reliably by vetting suppliers, testing assembled samples, controlling production, and managing shipping and customs. Follow these steps and you cut risk and win repeat business.

Data sources and links

- Bestingroup — Buy Edge Banding from China – Ultimate Guide. (bestingroup.com)

https://www.bestingroup.com/buy-edge-banding-from-china-ultimate-guide/ - Freightos — Importing & Exporting from China: documents, transit times and shipping tips (2025). (Freightos)

https://www.freightos.com/freight-resources/importing-exporting-from-china/ - Freight cost guide (2025) — Shipping China to USA (rates and transit times). (AMZ PREP)

https://amzprep.com/shipping-china-to-usa/ - Trade.gov — China import requirements and documentation guidance. (贸易局)

https://www.trade.gov/country-commercial-guides/china-import-requirements-and-documentation - Edge banding HS code & QC guides — manufacturer and industry references. (edgebandingmanufacturer.com)

https://edgebandingmanufacturer.com/what-is-the-hs-code-for-pvc-edge-band/

https://glowedgeband.com/quality-check