As a manufacturer or supplier, you might notice that furniture delivered to clients often experiences edge banding issues such as peeling, cracking, or detachment. These issues can result in product returns, customer dissatisfaction, and increased warranty claims.

Edge banding maintenance and repair should be an integral part of your quality assurance process. With the right tools and knowledge, you can reduce repair costs and maintain product quality, ensuring that your customers are satisfied with your products over time.

Edge banding is a critical part of furniture manufacturing, especially for high-end and custom pieces. The longevity of edge banding not only affects the aesthetics but also the durability of the final product. Understanding the causes of damage and taking preventive measures can save your business time, money, and potential reputational damage.

What Causes Edge Banding to Peel or Crack Over Time in Mass Production?

In a production line, the causes of edge banding damage can be more complex than in individual pieces. Identifying the root cause of damage allows manufacturers to optimize their processes and improve product durability.

Common Causes of Edge Banding Damage in Manufacturing

| Cause | Description |

| Poor Adhesive Quality | Low-quality adhesive may lead to premature peeling and cracking. |

| Improper Application | Inconsistent heat application during bonding can weaken the adhesion. |

| Handling and Transportation | Damaged edges often occur during packaging or transportation due to poor handling. |

| Wear and Tear from Use | Extended exposure to moisture, heat, or impact during the product’s lifecycle can degrade the banding. |

| Machine Calibration Issues | Incorrect settings on edge banding machines can lead to uneven application, causing defects. |

In mass production, it’s essential to ensure that the materials and processes involved in edge banding application meet quality standards to prevent costly repairs down the line.

Tools and Techniques for Efficient Edge Banding Repair

For furniture manufacturers, having the proper tools for edge banding repair is crucial in maintaining high-quality standards and minimizing product downtime. A streamlined repair process also reduces overhead costs and helps with inventory management.

Essential Tools for Repairing Edge Banding

| Tool/Material | Purpose |

| Edge Banding Machine | For precise and consistent edge banding application. |

| Heat Gun or Iron | For fixing heat-activated edge banding tape. |

| Trimming Tools | For neat trimming and finishing of applied banding. |

| Roller or Press | To ensure the banding adheres firmly during application. |

| Sanding Equipment | To smooth out rough edges and avoid sharp finishes. |

In larger production environments, having dedicated machines and equipment for edge banding can significantly improve efficiency and reduce manual errors.

Step-by-Step Process for Repairing Damaged Edge Banding in Mass Production

Manufacturers need a structured approach to repair damaged edge banding in both individual units and mass production. This process ensures minimal downtime and maintains consistent quality across batches.

Step 1: Identify the Damage

Regular quality checks during production can help identify defective edge banding early. Issues like peeling or misalignment should be immediately flagged for repair.

Step 2: Remove Damaged Banding

If damage is noticed, remove the affected banding carefully. For larger production runs, using automated trimming machines can speed up this process and ensure uniformity.

Step 3: Clean the Surface

A clean, smooth surface is essential for reapplying new banding. Dust, old glue, or debris can weaken the new bond, so ensure surfaces are thoroughly cleaned using industrial cleaning solutions.

Step 4: Apply New Edge Banding

Use an edge banding machine with properly calibrated settings to apply the new tape. Whether the banding is heat-activated or glued, applying the correct pressure and temperature is key to preventing future issues.

Step 5: Trimming and Finishing

After applying the new banding, use precise trimming tools to cut excess material and ensure clean edges. For high-quality finishes, sanding and polishing may be required to achieve a smooth, seamless look.

Preventing Edge Banding Damage in Mass Production

Preventing edge banding issues before they occur is more cost-effective than repairing them. Here are some steps that manufacturers can take to improve durability and reduce the risk of edge banding failures.

Key Prevention Methods for Edge Banding

| Prevention Method | Benefits |

| Standardized Application Process | Consistent application leads to better adhesion and fewer defects. |

| Invest in High-Quality Materials | Premium adhesives and edge banding materials ensure longer-lasting results. |

| Quality Control Checks | Regular inspection during and after production ensures issues are caught early. |

| Improve Packaging and Handling | Protective packaging can prevent edge damage during transportation. |

| Educate Production Teams | Training staff on proper techniques improves repair speed and reduces errors. |

By implementing these methods, manufacturers can significantly extend the lifespan of edge banding and reduce repair and replacement costs.

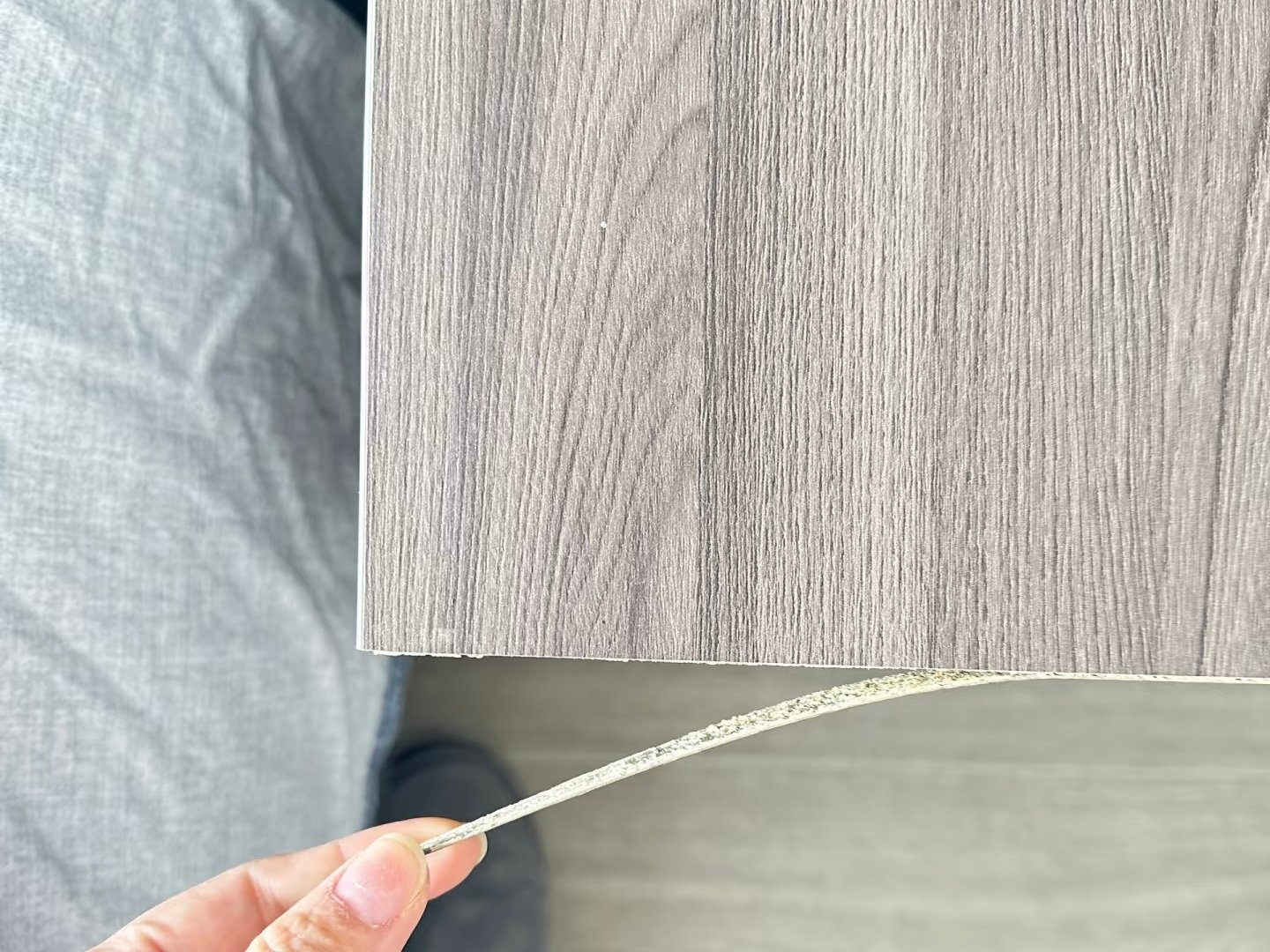

When to Replace Edge Banding Instead of Repairing It

For furniture suppliers, it’s important to know when it’s more cost-effective to replace edge banding rather than repair it. In certain cases, repeated repairs can lead to product degradation, and replacing the banding may be a more efficient solution.

Key Signs That It’s Time to Replace the Edge Banding

| Sign | What It Means |

| Banding is visibly warped | The wood underneath may be damaged or degraded. |

| Banding keeps detaching | Adhesive failure is widespread, and reapplication is ineffective. |

| Excessive cracking | The banding material has become brittle and cracked beyond repair. |

| Product integrity is compromised | Full replacement ensures a better, longer-lasting finish. |

If edge banding is beyond repair, replacing it entirely will ensure a higher-quality product and improve overall customer satisfaction.

Optimizing Edge Banding for Better Manufacturing Results

By understanding the causes of edge banding failure and implementing effective repair and prevention strategies, furniture manufacturers and suppliers can increase product longevity, reduce waste, and improve customer satisfaction. Regular quality control, proper training, and investment in quality materials will all contribute to more successful and efficient operations in the long run.