Struggling with color mismatches, peeling edges, and inconsistent batches? Poor quality control in PVC edge banding costs money and time.

Wholesale PVC edge banding suppliers use structured, multi-stage quality systems to ensure every roll meets strict standards for thickness, color, and durability across large orders.

If you want reliable quality from every shipment, you need to understand how suppliers control quality on massive orders. I’ll walk you through what they do, and what I check to protect my production.

How Large-Scale PVC Edge Banding Production Maintains Quality Consistency?

Ever received a bulk order and found half the rolls look different? Inconsistent PVC edge banding can shut down a line or lead to unhappy customers.

Large-scale producers build quality into the process, not just at the end. They rely on modern extrusion lines, automated measurement, and inline checks to keep every roll within tight tolerances. This starts with strict raw material control. Suppliers must verify PVC resin, pigments, and stabilizers before production, because the base mix determines flexibility, color stability, and long-term performance. Grade A PVC edge banding is engineered for uniform thickness and color accuracy, resisting warping or peeling when applied.

Key Production Factors That Ensure Consistency

Raw Material Standards

Suppliers work with trusted resin and pigment sources. Low-quality inputs lead to variation and rejects. Good factories test incoming batches for purity and composition before use.

Stable Extrusion Process

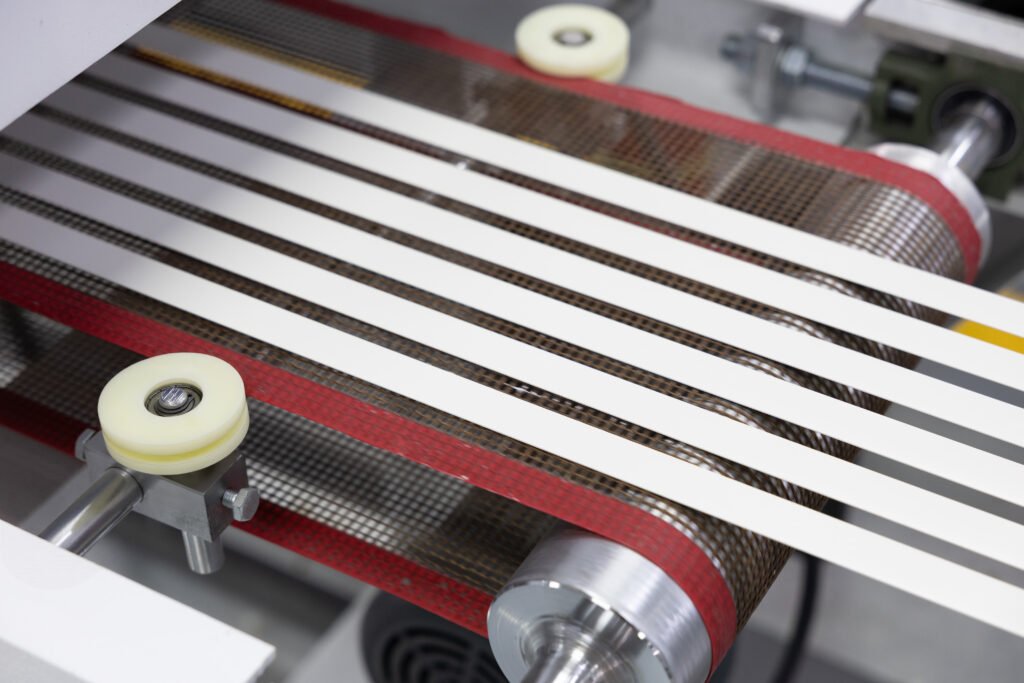

Automated extrusion ensures the same temperature and die settings across long runs. Modern lines can adjust speed and haul-off rate to maintain thickness within ±0.05 mm tolerances, a standard many factories aim for. Once the material exits the extruder, inline measurement gauges verify dimensions continuously.

Automated Surface Checks

Some factories use high-speed visual inspection systems that scan 100 % of the surface for pits, lines, or printing defects. These systems reduce human error and catch issues early.

Why This Matters for Large Orders

When you order thousands of meters, even small variation becomes visible on the furniture line. Automation and structured production help eliminate:

- Thickness drift that jams banding machines

- Color shift that clashes with panels

- Surface flaws that look cheap

In my experience, suppliers without inline QC lead to far more rejects and delays. That’s why I always ask for production process details before placing a big order.

What Quality Control Systems Wholesale Edge Banding Suppliers Use?

Good suppliers don’t guess quality. They document it. A proper quality control (QC) system covers checks before, during, and after production.

At the start, factories usually run raw material tests and check master batch formulas. This ensures the core characteristics like flexibility, adhesion capability, and color are locked in before running full orders.

During production, well-run plants place QC checkpoints along the line. These include:

- Thickness checks at regular intervals

- Color match comparisons against master samples

- Adhesion tests to verify molten glue integrity

These checks are documented. That documentation becomes your QC report if you ask for it.

Standard QC Stages and Tools

| QC Stage | What Is Checked | Tools Used |

|---|---|---|

| Raw Material | PVC resin, pigment mix | Lab scale, composition tests |

| In-Line Production | Thickness, color | Inline gauges, spectrophotometer |

| Surface Inspection | Defects, emboss match | Vision systems, operator checks |

| Pre-Shipment | Finished roll audit | Random sampling, QC report |

Factories that use this level of QC often follow internal SOPs and may align with ISO 9001-like frameworks, though not all will list formal certification. When you see QC reports with numbers (e.g., thickness tolerances, color delta results), you know the process is data-driven, not guesswork.

How Batch Tracking and Color Management Prevent Variations in Bulk Orders?

One of the biggest problems with bulk PVC edge banding is batch variation. If one batch has a slightly different pigment mix, you’ll see visible stripes on a finished furniture set. Suppliers control this with batch tracking and color management protocols.

Batch Tracking: Keeping Rolls Linked

Factories assign a unique batch number to every run. This number travels with the product from extrusion to package. It lets you and the supplier trace back to the day’s raw materials and machine settings if any issue arises.

In addition, suppliers store master samples for each color and style. These become the reference point for future orders so that new runs match older ones even months later.

Color Matching and Spectrophotometry

Color is measured with digital tools. Inline spectrophotometers scan a moving strip and compare its color to the stored master sample thousands of times per minute. If the color deviates beyond an accepted threshold (often a specific Delta E value), the line pauses for adjustment.

This system keeps batches aligned so:

- Every batch of the same color stays consistent

- Across multiple orders, furniture lines match

- Gloss and texture match customer expectations

These tools also reduce the risk of human subjective error, which is common when workers judge color by eye alone.

How Wholesale Factories Test PVC Edge Banding Before Shipment?

Testing before shipment is the final gate. Your supplier should check finished rolls for the characteristics that matter most in production.

Common Pre-Shipment Tests

A reliable supplier will include:

- Color and gloss checks – Ensuring batches match approved samples.

- Thickness and width measurement – Confirming tolerances stay within spec.

- Adhesion testing – Verifying edge banding adheres correctly at typical application temperatures.

- Surface defect checks – Spotting imperfections that might affect finish quality.

Before shipment, many factories do final visual and machine checks. Some even share formal batch quality reports with clients, showing test results for every key metric.

Why Pre-Shipment Test Matters

If issues slip through, you get them — not the factory. Pre-shipment checks catch problems in good time so your production doesn’t get held up by:

- Rolls with wrong color

- Samples out of tolerance

- Rolls that jam your edge bander

I always ask my suppliers for a pre-shipment QC summary before I pay the balance. It gives me confidence that what I’m about to receive already passed tests that matter.

How Furniture Factories Can Verify a Supplier’s Quality Control Capability?

You can’t take a supplier’s word on quality. You must verify it.

Ask for QC Documentation

Good suppliers will show you:

- Master sample records

- QC checkpoints and tools used

- Batch reports with test values

If they refuse, that’s a red flag.

Request Production Photos or Video

Ask for images or short videos of the extrusion line and inline checks. Suppliers using modern systems are happy to share this because it proves they invest in quality.

Physical Samples and Lab Tests

Never approve bulk production based only on photos. Physical samples help you check:

- Match to your boards

- Thickness tolerance

- Adhesion after heat and humidity exposure

You can even hire a third-party inspector like SGS or Intertek to audit the factory and test samples for detailed verification.

Clear Communication of Standards

Make sure the supplier clearly defines tolerance limits (e.g., ±0.05 mm thickness) and color deviation thresholds (e.g., Delta E value). If they can’t quantify quality, you don’t have assurance.

Conclusion

Good quality control in PVC edge banding comes from proper systems, traceable batches, and visible testing at every step. Data sources include supplier QC guides and industry tests for PVC edge banding processes.

Sources:

• Wholesale PVC QC & import guide – EdgeBandCT: https://edgebandct.com/wholesale-pvc-edge-banding-what-distributors-should-know-before-importing/

• Inline color & defect inspection process – PVC DecorativeFilm QC checklist: https://pvcdecorativefilm.com/what-quality-checks-define-our-1mm-pvc-edge-banding/ (中国PVC装饰膜厂家)

• Supplier quality testing examples – MaxaveGroup edge banding quality tests: https://www.maxavegroup.com/pvc-edge-banding/ (Maxave)