Struggling with laser edge banding issues can slow down your furniture production and raise costs quickly.

Laser edge banding problems often come from material mismatch, machine settings, or environmental factors. Knowing common issues and how to fix them can save time and money.

If you want your laser edge banding to work smoothly, you need to understand the problems and their solutions. Let’s explore these step by step.

Common Laser Edge Banding Issues Faced by Furniture Manufacturers?

Many furniture makers face issues like peeling edges, discoloration, or poor adhesion during laser edge banding.

The most common problems include weak bonding, yellowing edges, bubbles, or uneven finishing that affect the furniture’s look and durability.

Common Problems Explained

| Problem | Description | Impact on Product |

|---|---|---|

| Peeling Edges | Edges separate after some time | Weak bond, reduces durability |

| Discoloration | Edges turn yellow or dark | Aesthetic issues, looks cheap |

| Bubbles | Small air pockets between edge and panel | Weak bond and rough texture |

| Uneven Finish | Glossy and matte areas mixed irregularly | Poor visual and tactile feel |

These problems happen because of wrong materials, machine settings, or environmental conditions like humidity. Knowing these can help you identify the root cause faster.

What Causes Defects in Laser Edge Banding Processes?

Laser edge banding defects usually come from machine errors, wrong materials, or environmental issues.

Most defects result from incorrect laser power, poor tape quality, or improper panel moisture levels. These factors disrupt the bonding process.

Causes of Common Defects

- Laser Power Issues: Too high or too low power damages the tape or panel.

- Tape Quality: Low-quality edge banding tape doesn’t bond well.

- Panel Moisture: Wet or damp panels prevent good adhesion.

- Machine Calibration: Misalignment or worn parts reduce bond strength.

| Cause | Effect on Process | How to Check |

|---|---|---|

| Laser Power | Burning or weak adhesion | Monitor laser settings |

| Tape Quality | Poor bond, peeling edges | Use certified tapes |

| Panel Moisture | Bubble formation, poor bonding | Test panel moisture level |

| Machine Calibration | Uneven edge banding | Regular maintenance and checks |

Understanding these causes helps to improve process control and reduce errors in production.

How to Troubleshoot Laser Edge Banding Problems Step by Step?

When problems occur, a clear troubleshooting method saves time and waste.

Start by checking machine settings, then materials, and finally environmental factors to find and fix the problem quickly.

Step-by-Step Troubleshooting Guide

- Check Laser Power and Speed

Make sure the laser power matches the tape and panel type. - Inspect Edge Banding Tape Quality

Use samples from trusted suppliers. - Measure Panel Moisture Content

Keep moisture below recommended limits. - Examine Machine Parts

Clean and adjust nozzles, guides, and sensors. - Run Test Samples

Check for defects before full production.

| Step | What to Do | Why It Matters |

|---|---|---|

| Laser Settings | Adjust power and speed | Ensures proper tape melting |

| Tape Quality | Test different tapes | Prevents poor bonding |

| Panel Moisture | Use moisture meter | Avoids bubbles and peeling |

| Machine Maintenance | Clean and calibrate | Keeps process consistent |

| Sample Testing | Run small batches first | Detects problems early |

Following these steps helps find problems fast and keeps production on track.

Best Practices to Prevent Laser Edge Banding Failures?

Avoiding failures is better than fixing them later. Consistent care improves quality.

Good material choice, proper machine maintenance, and controlled environment reduce laser edge banding failures.

Key Prevention Tips

- Use certified laser edge banding tapes designed for your machine.

- Keep your machines clean and well-calibrated.

- Maintain stable workshop temperature and humidity.

- Train operators regularly on machine use.

- Monitor panel moisture and store materials properly.

| Practice | How to Do It | Benefit |

|---|---|---|

| Use Quality Tapes | Buy from trusted suppliers | Better adhesion, no peeling |

| Machine Care | Regular cleaning and calibration | Consistent bonding quality |

| Control Environment | Use dehumidifiers or heaters | Prevents moisture problems |

| Staff Training | Conduct regular workshops | Reduces operator errors |

| Material Storage | Store panels in dry, cool areas | Keeps moisture low |

By following these steps, you reduce defects and boost your furniture quality.

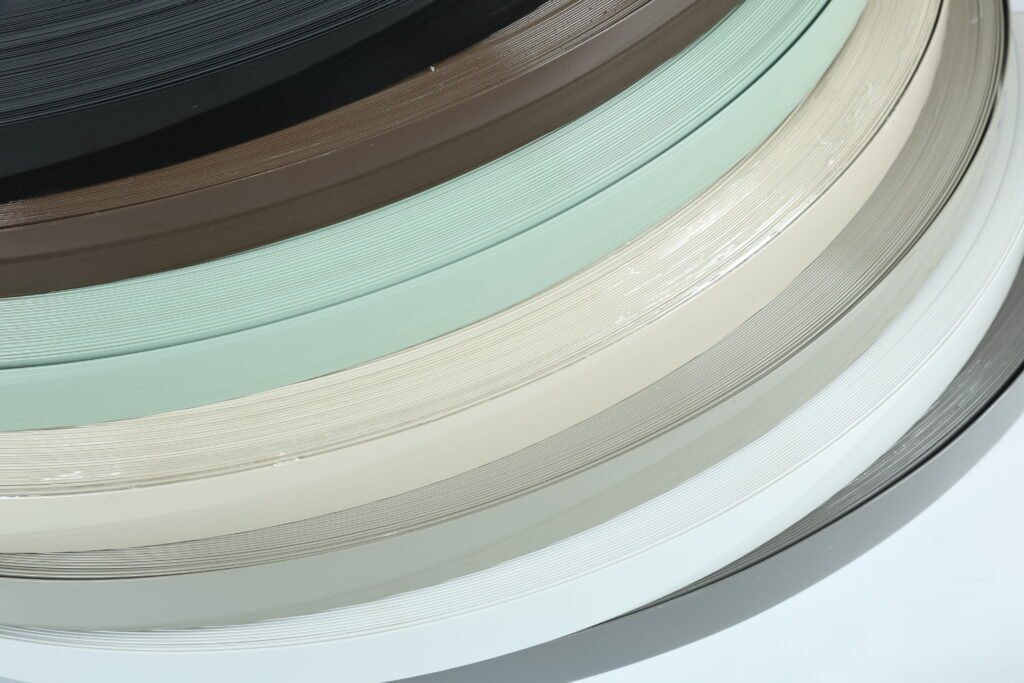

Choosing the Right Edge Banding Tape for Laser Application?

The right tape is key for good results in laser edge banding.

Choose laser edge banding tape based on material compatibility, thickness, and finish to avoid bonding and appearance problems.

How to Pick the Right Tape

| Factor | What to Consider | Why It Matters |

|---|---|---|

| Material Type | PP, ABS, PMMA | Different bonding and finish |

| Thickness | Match panel edge thickness | Prevents gaps or overhang |

| Color and Finish | Match furniture design | Aesthetic consistency |

| Laser Compatibility | Designed for laser bonding | Ensures clean edge and bond |

I always recommend testing tape samples before bulk buying. This way, you can avoid wasting materials and money.

Conclusion

Laser edge banding problems are common but fixable with the right knowledge and care. Understanding causes and solutions improves your furniture’s quality and your production efficiency.