Edges that fail on site cost money and trust. I have seen distributors lose sales over avoidable supplier issues. I will show what to check and how to choose a partner that keeps projects moving.

A reliable edge banding partner provides consistent color, clear proofs, steady lead times, and fast support — not just low prices. Follow a simple supplier checklist to reduce returns and grow your business.

I will walk you through the key choices. I use plain steps and real checks you can use when vetting suppliers. Read on and save the checklist for your next supplier call.

Understanding the Importance of Reliable Supplier Partnerships in Edge Banding?

Suppliers shape your product performance. A weak partner creates rework and returns. I explain why this relationship matters for distributors.

Good suppliers cut risk. They keep colors stable, meet lead times, and provide proof. That protects margins and reputation.

Dive deeper: business risks, cost of failure, and the value of stability

I will break the problem into clear business effects so you can justify the checks.

First, returns cost real money. When an edge does not match, you pay freight, rework, and lost labor. You may lose repeat orders. These costs quickly exceed small per-unit savings from a cheap supplier. Second, slow or erratic lead times force higher stock levels. That ties up cash and increases storage cost. Third, poor documentation and weak testing make disputes hard to resolve. You need spectral files, TDS, and sample reports to prove a batch was out of spec.

A reliable partner reduces these risks. They run QC tests and keep records. They provide measured samples and clear batch tolerances. They can show ISO-style controls or supplier quality processes. That gives you evidence if a batch fails later. Their faster lead times let you hold less stock and win rush jobs. Good partners also help with technical questions like glue compatibility or emboss settings.

I once worked with a dealer who switched to a partner that supplied spectral data and glued mockups. Returns dropped. Orders rose. The dealer traded lower unit cost for lower risk and higher wins. That is the core value of a strong supplier relationship.

Key Qualities to Look for When Choosing an Edge Banding Supplier?

Not all suppliers are the same. You must test for specific capabilities. I list the qualities I insist on before I commit.

Look for production consistency, color control, proofing workflows, flexible MOQs, and clear commercial terms. Ask for evidence, not promises.

Dive deeper: measurable supplier attributes, questions to ask, and red flags

Here are the attributes I check, and how I test them.

1. Quality systems and audits. Ask if the supplier has formal processes for supplier quality management. A supplier that follows ISO-style controls or documented QC processes shows discipline. Ask for test records, internal audit results, or third-party certificates. If they cannot show any process, that is a red flag.

2. Color and finish control. Demand measured data. Ask for spectral files (Lab) and gloss readings for any sample. Prefer suppliers who use industry tools like X-Rite and can deliver spectral files. Ask what ∆E method they use (CIEDE2000 preferred). If they rely on photos alone, do not accept that.

3. Proofing workflow. A clear sample-first workflow matters. The supplier should offer extruded sample rolls, glued mockups, and short pilot runs. They should document acceptance criteria. Suppliers who accept small pilots show flexibility. Those who insist on large MOQs can be risky for new decors.

4. Lead time and logistics. Ask for typical lead times, escrows for stock, and options for regional warehousing. Fast, predictable lead times let you reduce safety stock. Ask for on-time delivery metrics or case studies. If lead times vary wildly, plan for higher inventory or find another supplier.

5. Communication and after-sales support. Test response speed on a small question. Good suppliers reply fast and give clear technical data. After-sales support should include rework options and clear return policies. If they avoid written tolerances or warranties, treat them with caution.

Use this quick checklist when you talk to suppliers:

| Check | Why it matters | Ask for |

|---|---|---|

| QC process | Reduces defects | QC docs, ISO mention |

| Spectral data | Real color proof | Lab files, device info |

| Sample workflow | Lowers risk | Pilot terms, MOQ |

| Lead time | Inventory planning | Typical lead days, OT% |

| Support | Fix problems fast | SLA, return policy |

I only move to commercial terms after the supplier passes these checks. If you want, I can turn this into a short supplier questionnaire you can email to prospects.

Evaluating Product Consistency and Color Matching Capabilities?

Color and texture make or break sales. You must verify how the supplier matches and controls these variables. I show the tests and tolerances I use.

Demand spectral files, require glued mockups, and set numeric tolerances for ∆E and gloss. Use a written acceptance report as the contract.

Dive deeper: tools, test procedures, and acceptance criteria

I use a step-by-step testing protocol with suppliers. Use it as your standard.

Step 1 — Reference sample and lighting. Send the actual board sample and photos of the intended lighting (store, showroom, daylight). Lighting causes metamerism. Ask the supplier to test under D65 and warm LED too.

Step 2 — Measured sample. The supplier supplies an extruded roll with Lab and spectral file. They also provide gloss readings at the agreed angle (60° or 85°). I check the device used and geometry. Sphere geometry is better for textured surfaces.

Step 3 — Glue and re-measure. I insist on a glued mockup using the intended adhesive and edgebander. Some pigments shift after glue or heat. Re-measure the Lab and gloss after cure. If numbers shift beyond tolerance, reject the batch.

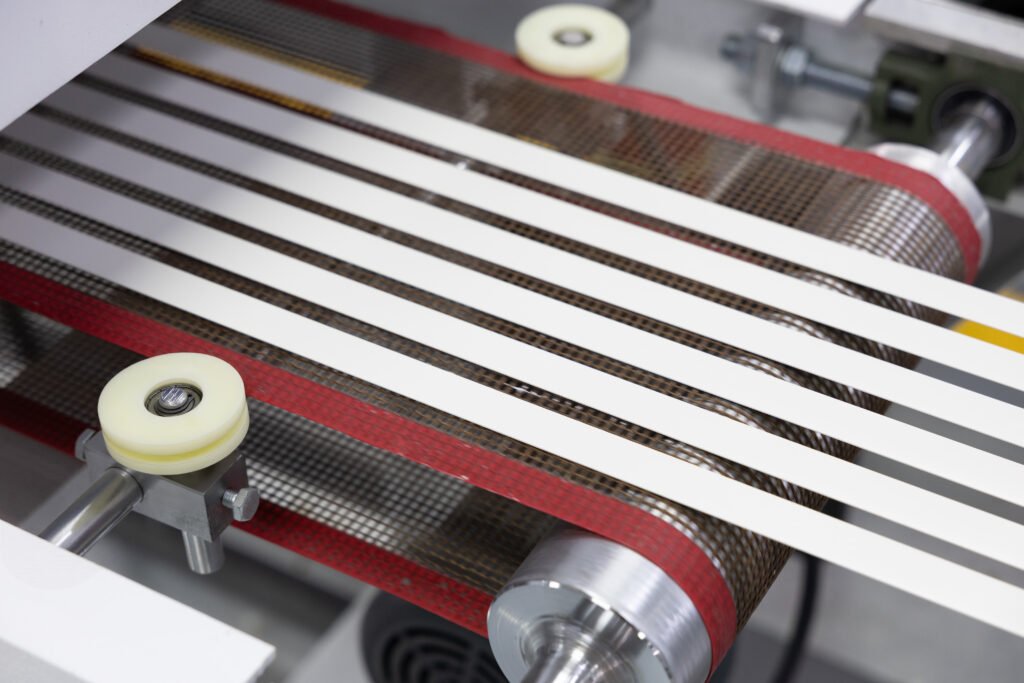

Step 4 — Pilot run and inspection. Run a small batch. Inspect for streaks, emboss collapse, and winding defects. Use simple inline checks and visual audits. Ask for batch spectral files and a QC report for the pilot.

Acceptance targets I use:

| Measure | Typical target |

|---|---|

| Color ∆E (CIEDE2000) | ≤ 2 for premium, ≤ 3 standard |

| Gloss variance | ±5 gloss units |

| Thickness tolerance | Supplier spec ±0.05 mm |

| Adhesion (peel test) | Industry standard pass |

If the supplier cannot deliver these tests, you trade safety for a bargain. I prefer suppliers who keep measurement records for each batch. That record helps if a customer complains later.

The Role of Communication, Lead Time, and After-Sales Support?

Clear communication, predictable lead times, and fast support keep your customers happy. I explain what service levels you should demand.

Good partners answer technical questions fast, publish lead time expectations, and handle nonconformance promptly. That protects project timelines and your margins.

Dive deeper: SLA items, logistics options, and dispute resolution

Ask suppliers for a basic service level agreement (SLA). It need not be legal-heavy. Include these items:

- Response time for technical queries (e.g., 24–48 hours).

- On-time delivery target and measured OT% (on-time percent).

- Pilot turnaround time for sample proofs.

- Return/rework policy with timelines and cost responsibility.

Logistics options matter. Ask about regional warehousing, partial shipments, and express reorders. A supplier with regional stock can cut your lead time from weeks to days. That wins you urgent jobs.

Dispute resolution is practical. Keep written batch tolerances and sample approvals as evidence. Ask the supplier to sign an approval document for each approved sample. That reduces argument later.

Communication style is also a clue. Short, precise answers and files (spectral, photos, QC reports) show discipline. Long vague answers show disorganization. Test them with a small technical question first.

How CT Edgeband Builds Trust-Based Partnerships with Global Distributors?

I describe how CT Edgeband approaches partnerships. They focus on proofs, flexible MOQs, and clear logistics. That is the model I recommend.

CT Edgeband offers measured sample proofs, small pilot runs, and support for regional stocking. They document tolerances and help with technical onboarding. That reduces buyer risk.

Dive deeper: partnership model, sample packs, and onboarding steps

CT Edgeband builds partnerships with a simple onboarding flow I use with new dealers.

Onboarding steps they use:

- Reference share. Distributor sends board samples and lighting notes.

- Measured proof. CT Edgeband supplies spectral files, gloss readings, and an extruded sample.

- Glued mockup test. Proof is bonded and re-measured to check shifts.

- Pilot run. Small MOQ pilot, tracked with QC report.

- Stock program. For winners, CT Edgeband holds small stock in regional hubs.

CT Edgeband also publishes case studies and testing guides. That transparency helps buyers trust them quickly. If a supplier offers the same level of proof and logistics, you can lower your inventory risk and pitch with confidence.

Conclusion

Choose partners that prove color, control quality, meet lead times, and back their work with clear support. Measure, document, and require proof before full orders.

Data sources and links

- X-Rite — Guide to Understanding Color. https://www.xrite.com/-/media/xrite/files/whitepaper_pdfs/l10-001_a_guide_to_understanding_color_communication/l10-001_understanding_color_en.pdf. (xrite.com)

- X-Rite — Color iQC / iMatch how-to guide. https://www.xrite.com/-/media/xrite/files/apps_engineering_techdocuments/c/color_imatch_iqc/03_how-to-guide_en.pdf. (xrite.com)

- EGGER — Decor Match System and Edge Banding. https://www.egger.com/en/decorative-collection/decor-match-system. (egger.com)

- IMARC Group — Edge Banding Materials Market Report 2025-33. https://www.imarcgroup.com/edge-banding-materials-market. (IMARC Group)

- ISO / Supplier Quality guidance (Ideagen): ISO 9001 supplier management guide. https://www.ideagen.com/thought-leadership/blog/iso-9001-supplier-management-your-step-by-step-guide. (ideagen.com)

- StockIQ / Lead time importance. https://stockiqtech.com/blog/delivery-lead-times/. (StockIQ Technologies)