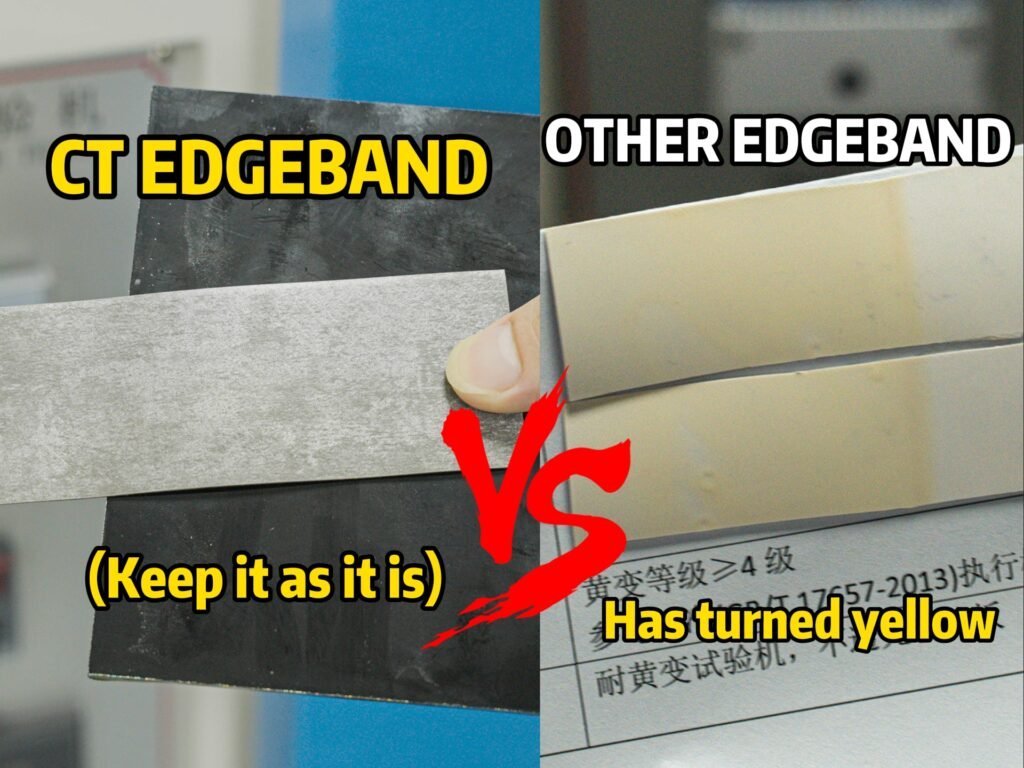

We test every batch of Chaotai’s edge band for UV exposure, heat, and time。CT yellowing resistance tests simulate years in just hours — ensuring your furniture stands the test of time.

Precise control over raw material moisture content is critical for many manufacturing processes, directly impacting product quality, consistency, and preventing costly defects.

It allows us to verify the material's elasticity and resilience, ensuring our edge bands won't crack or break during application, especially around tight curves, and will maintain their integrity over years of use.

This rigorous testing ensures our edge bands maintain their original color and finish over time, resisting yellowing and fading even in bright, sunny environments.

It is necessary to test the performance of the back coating of the edge banding strip before leaving the factory, and the final tensile force of the edge banding strip glued to the board.

—— See how our edge banding performs under real-world stress.——

In an environment of minus 200 degrees, other edge bands become extremely fragile, while the Chaotai’s edge band maintains its inherent properties.

Back coating is used as a bridging agent between the edge banding strip and the glue. After the Chaotai’s edge band strip is torn off, there are a lot of sawdust, and the adhesion is very good!

We use numerical values to test the adhesion of the edge banding. The data shows that the maximum tensile force of the Chaotai’s edge band can reach 15-20 Nm, which is equivalent to the hand force required to screw a stuck car tire nut

Drop us a message and we’ll help you plan your order efficiently.

We will send a product manager to contact you within 24 hours