I lost a big order once because the edge looked cheap. I fixed that and my margins later rose. (PAS)

Edge banding hides raw cores, improves durability, and finishes the look. It turns a cheap panel into a piece that reads premium at first glance.

Good design needs small details. Keep reading and I will show how edge choices shape perceived quality, touch, and brand value.

Why Edge Banding Is Essential for a Premium Furniture Finish?

I once saw a well-painted cabinet fail because its raw edge showed. That single flaw lost the sale. (PAS)

Edge banding completes the surface. It seals the core. It protects against chipping and water. A neat edge makes the whole piece look intentional and higher end.

Dive deeper: function, protection, and first impressions

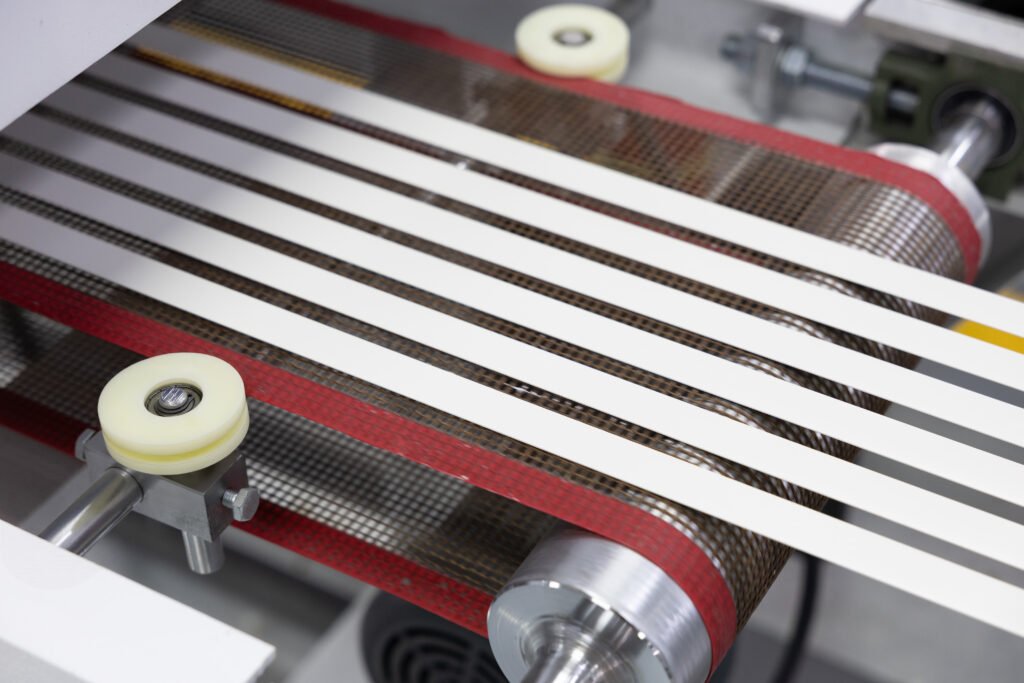

Edge banding has three main roles. It covers exposed panel core. It protects the edge from impact and moisture. It gives a continuous surface look that the eye reads as quality.

First, protection matters. Many engineered boards hide their core with banding. The band keeps moisture out. That increases life in kitchens and baths. It also prevents chips during handling. For higher-value pieces, that durability is expected.

Second, visual continuity matters. A board with matching banding reads like a single, continuous material. That trick raises perceived value. Designers use continuous grain and matching sheens to make panels look like solid wood or high-end laminate. Laser and heat-bond techniques let the join almost disappear. These fine joins instantly read as premium.

Third, finish and assembly matter. If the edge band is a poor material or wrong sheen, it will read as an afterthought. I always ask for a proof—edge on board—before full runs. I also keep a sample book so salespeople can show assembled samples to clients. That step avoids surprise rejections at install.

In my experience, edge banding reduces returns and improves buyer confidence. A clean edge is a small cost. The return on that cost shows fast in fewer claims and stronger repeat orders.

How Edge Banding Influences Perceived Quality and Design Value?

A client once said the edge “made the piece feel cheap.” I learned to treat the edge as a design element. (PAS)

Edges influence how people judge a piece. A matched edge raises perceived craftsmanship. A mismatched or glossy sticker edge lowers perceived value. Designers notice this first.

Dive deeper: psychology, visual cues, and specification points

Perception is visual first, tactile second. People look at corners and seams when they judge finish. The edge sits at a high-attention spot. If the edge reads as a separate layer, buyers see a join. That join can mark the piece as lower grade.

From a psychological view, continuity signals craft. Matching grain, color, sheen, and texture makes the piece read as whole. I often ask: does the edge talk to the surface or shout against it? The right answer wins clients.

Design value also depends on execution. Here are the practical cues I control:

- Grain alignment. Match the pattern repeat and direction when possible. Aligned grain feels deliberate.

- Color and gloss match. If the edge is even slightly off in gloss, the difference catches the eye. I measure gloss and use the same sheen family for edges and faces. Konica Minolta and gloss standards help set targets (GU at 60°, 20°, or 85° depending on range).

- Seam quality. Tight seams—laser or hot-air joints—reduce shadow lines. Those reduced shadows look finer and more crafted. Henkel and industry guides note that laser bonding often creates the finest joins and a higher-quality visual impression.

I make sure spec sheets include edge code, texture name, and target GU. That set of data moves decisions from “looks right” to “measured and approved.” I find clients sign faster when they can hold an assembled approval sample.

Material, Texture, and Gloss: The Key Factors Behind a Luxurious Look?

I once compared two identical cabinets. One used matte textured edging. The other used glossy tape. Buyers chose the textured one every time. (PAS)

Material, texture, and gloss shape both sight and touch. Smooth, natural textures feel warm. High gloss reads sharp and modern. The right mix creates luxury.

Dive deeper: how to choose materials and set specs (with a quick table)

Material choice affects look and performance. Common edge materials include PVC, ABS, PET, veneer, and acrylic. Each has pros and cons. PVC and ABS are flexible and cost-effective. PET and acrylic offer cleaner matte or high-gloss results. Real veneer gives a natural edge but needs careful joint work.

Texture influences tactile feel. Smooth finishes suggest polish and modernity. Woodgrain textures add warmth. Micro-textures hide fingerprints and small scratches. Studies show that natural and smooth wood surfaces score higher in positive touch reactions. I use those findings when specifying finishes for living and bedroom furniture.

Gloss changes perceived color and sharpness. High gloss reflects more light and boosts contrast. Matte scatters light and looks softer. I measure gloss with a glossmeter and set GU targets. Typical practical guidance:

- Matte / low sheen: 0–20 GU (60° measure)

- Satin / semi-matt: 20–40 GU

- Semi-gloss to high-gloss: 40+ GU (use 20° for very high gloss)

| Factor | Effect on look | When I use it |

|---|---|---|

| Veneer edge | Natural, warm, premium | High-end furniture |

| Textured PET/PVC | Hides wear, tactile warmth | Kitchens, wardrobes |

| High-gloss ABS/acrylic | Sharp, modern, premium visual | Retail, gloss-focused lines |

| Matte PET | Modern, low-reflective, hides prints | Bedrooms, living rooms |

I always assemble a proof built from the actual board and edge. I view it under target lighting. That step reveals interactions between texture and gloss that numbers alone miss. It also prevents a glossy edge from reading like a sticker on a matte board.

Matching Edge Banding with Board Designs for Seamless Aesthetics?

A poor color match once cost me a showroom placement. I now map board codes to edge SKUs and keep a sample passport. (PAS)

Matching color, grain, and sheen is part data work and part craft. Good matches require measurement, samples, and traceability.

Dive deeper: workflow, tools, and a sample mapping table you can copy

I use a simple workflow to ensure matches.

- Get full board spec: decor code, texture name, gloss target, and lot number.

- Pull or request a physical board sample.

- Produce an edge pilot strip in the proposed material and texture.

- Measure color (spectrophotometer) and gloss (glossmeter). Save Lab and GU values.

- Assemble a proof and sign off.

I keep a mapping table that links board code to approved edge SKU and tolerance. Here is a sample format I use internally.

| Board code | Texture | Gloss (GU) | Approved edge SKU | Notes |

|---|---|---|---|---|

| EG-PL-123 | Supermatt oak | 12 GU | EDGE-PET-OC123 | Match grain direction |

| ARAU-45 | Woodgrain L | 25 GU | EDGE-PVC-WG45 | Use matte embossing |

| LAC-99 | High gloss white | 85 GU (20°) | EDGE-ACRY-GL99 | Use polished ABS, measure at 20° |

Tools I use include spectrophotometers and established brand cross-reference charts. I also maintain a sample book with assembled proofs per lot. This “passport” lets me quote accurately and ship with confidence.

Metamerism is a risk. Two materials can match under one light and not under another. I always view proofs under the client’s intended lighting when possible. That check avoids color surprises on-site.

How Premium Edge Banding Helps Furniture Brands Stand Out in the Market?

I helped one brand move from undifferentiated commodity to a premium niche. Their edge choices played a major role. (PAS)

Premium edge banding reduces returns and raises perceived quality. It also becomes a marketing point. Brands that control edge detail stand out.

Dive deeper: commercial benefits, KPIs, and how to sell the edge as a value-add

Edge choices affect margins and brand trust. Here are the key business outcomes I track and use in sales conversations:

- Lower claims and returns. Good edges mean fewer field failures.

- Faster approvals. Assembled proofs reduce time to sign contracts.

- Higher perceived price. Well-executed edges let brands command higher prices.

- Better reviews and referrals. Small visible quality wins yield word-of-mouth.

I recommend brands invest in a small sample library and a short spec sheet that sales teams can use. That packet should include images, Lab/GU data, and a short note on recommended care. It becomes an easy sell point: “We match color, texture, and gloss to your board so the piece reads premium.”

On the production side, I ask for traceability. If a batch fails, I want to see board lot, edge lot, glue, and operator. That traceability makes fixes fast and prevents repeat failures.

In short, premium edges are not a cost center. They are an investment that pays through fewer claims, higher prices, and better brand reputation.

Conclusion

I use measured matches, assembled proofs, and the right edge materials to make furniture read premium. That work wins clients and protects margins.

Data sources and links

- Table-Space — The Essential Guide to Edge Banding for Professional Use. https://table-space.com/index.php?a=show&c=content&id=885. (Table Space)

- Henkel Adhesives — Choosing the right edgebanding technology; laser joins and appearance. https://next.henkel-adhesives.com/us/en/articles/choosing-right-edgebanding-technology-in-volatile-furniture-market.html. (henkel-adhesives.com)

- Konica Minolta Sensing — Understanding Gloss Standards & Units. https://sensing.konicaminolta.us/us/blog/understanding-gloss-standards-units/. (Konica Minolta Sensing)

- Frontiers in Psychology — Sensory and Emotional Perception of Wooden Surfaces. https://www.frontiersin.org/articles/10.3389/fpsyg.2017.00367/full. (Frontiers)

- Woodworking Network / Industry guides on edge banding and finish quality. https://www.woodworkingnetwork.com/best-practices-guide/gluing-laminating-veneering/what-know-about-edgeband-color-matching. (hmcutworks.co.uk)