Finding the right panel supplier can feel like a gamble. The wrong choice affects product quality, costs, and delivery time. Let me help you avoid that mistake.

The top 10 engineered wood panel manufacturers in North America are known for consistent quality, strong supply chains, and product variety for furniture, cabinets, and construction use.

I’ve worked with clients across the globe who care about consistency, surface quality, and sustainability. In this article, I’ll break down the key players and how to choose the right one for your project.

What Are Engineered Wood Panels and Why Are They Widely Used in North America?

Wood panels are everywhere. But natural wood can’t meet the speed, volume, or price needs of modern furniture makers.

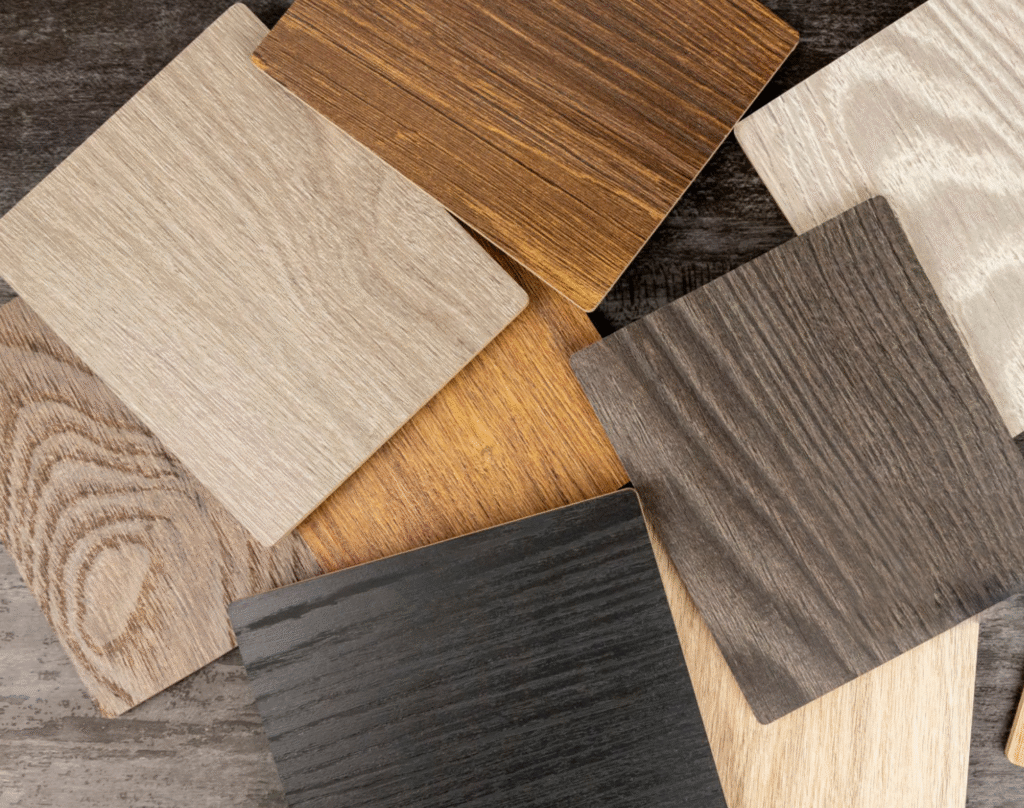

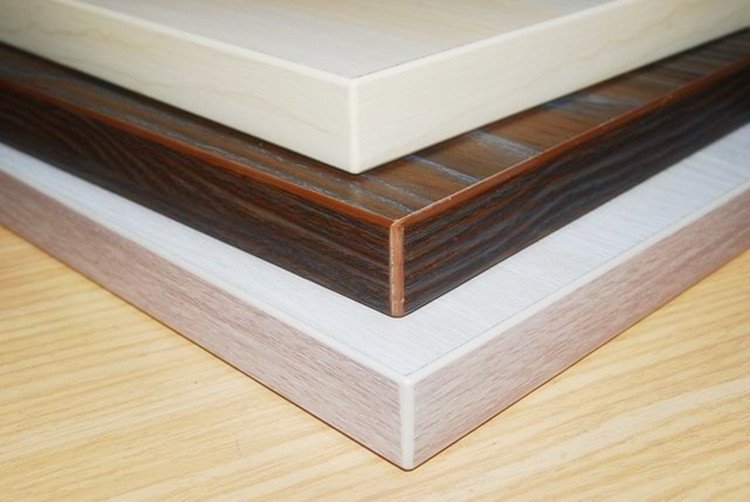

Engineered wood panels are man-made boards like MDF, plywood, and particleboard. North American brands use them because they’re cost-effective, stable, and easy to process.

What Types Are Most Common?

There are several types used in the furniture and interior industries:

| Type | Description | Common Uses |

|---|---|---|

| MDF | Smooth, dense, great for painting | Cabinets, doors, panels |

| Particleboard | Made from wood chips and glue, low cost | Furniture cores, shelving |

| Plywood | Layered wood veneer, stronger than others | Structural parts, kitchen cabinets |

| OSB | Compressed strands, strong and affordable | Flooring, wall sheathing |

| HDF | High-density version of MDF | Laminate flooring, door skins |

These materials are flexible and reliable. That’s why manufacturers across North America rely on engineered wood for both residential and commercial projects.

How to Evaluate a Reliable Engineered Wood Panel Manufacturer?

I used to look at price first. Big mistake. Quality issues, returns, and delays ended up costing more.

A reliable wood panel manufacturer offers consistent quality, clear technical data, sustainability certifications, and reliable delivery times.

What Really Matters When Choosing a Manufacturer?

You should look beyond the product photo. These are the key factors I’ve learned to focus on:

1. Quality Control

- Ask about raw material sources

- Check for warping resistance

- Test moisture content and density

2. Certifications

| Certification | What It Means |

|---|---|

| CARB / TSCA Title VI | Low formaldehyde emissions (USA standard) |

| FSC / PEFC | Sustainable forest sourcing |

| ISO 9001 | Quality management system |

3. Technical Support and Documentation

A good supplier gives full data sheets, test reports, and responds fast. I once worked with a mill that couldn’t send thickness tolerance specs—never again.

4. Delivery and Packaging

- Are they on time?

- Do they prevent moisture damage in transit?

- Can they handle full container orders?

These basics build trust over time. When I find a partner who gets this right, I stick with them.

Overview of the Top 10 Engineered Wood Panel Manufacturers in North America

When I help clients find a panel supplier in North America, I start with these ten. They lead in volume, quality, or innovation.

The top 10 engineered wood panel manufacturers in North America include Columbia Forest Products, Roseburg, Arauco, and others who serve both residential and industrial markets.

Who Are the Major Players?

| Brand Name | Base Country | Specialty Products | Key Strengths |

|---|---|---|---|

| Columbia Forest Products | USA | Hardwood plywood | Formaldehyde-free, eco-friendly |

| Roseburg Forest Products | USA | MDF, particleboard, plywood | Vertically integrated, consistent |

| Arauco North America | Chile / USA | MDF, particleboard, TFL | Large capacity, design range |

| Georgia-Pacific | USA | OSB, plywood, softwood panels | Construction market leader |

| Weyerhaeuser | USA | OSB, structural panels | Forest-owned, high-volume supply |

| West Fraser | Canada | MDF, OSB, plywood | North American footprint |

| Boise Cascade | USA | Plywood, OSB | Home construction and remodel focus |

| Canfor | Canada | OSB, plywood | Sustainable forestry-based products |

| RoyOMartin (Martco) | USA | OSB, MDF | Family-owned, southern U.S. stronghold |

| LP Building Solutions | USA | OSB, structural panels | Known for LP SmartSide siding |

Each of these has regional distribution networks and product focus. Some are better for cabinetry, others for construction-grade panels.

Comparing Engineered Wood Products Offered by Leading Brands

Some clients think all MDF is the same. It’s not. Even from top brands, specs vary. That’s why we always ask for data sheets.

Leading panel manufacturers in North America offer a range of MDF, particleboard, OSB, and plywood products with different densities, finishes, and application ratings.

How Do These Products Compare?

Let’s break it down by performance and best use:

1. Strength and Density

| Product | Density (avg) | Strength Level | Use Case |

|---|---|---|---|

| MDF | 700–850 kg/m³ | Moderate | Painted furniture, cabinet fronts |

| HDF | 850–950 kg/m³ | High | Flooring, heavy doors |

| Particleboard | 600–700 kg/m³ | Low to moderate | Carcass, budget furniture |

| OSB | 600–650 kg/m³ | High | Flooring, structural sheathing |

| Plywood | 500–700 kg/m³ | High | Load-bearing applications |

2. Moisture Resistance

- Roseburg offers MR-grade MDF

- LP and Weyerhaeuser OSB panels are rated for outdoor or humid zones

- Arauco’s Trupan MR line performs well in bathroom cabinetry

3. Sustainability Focus

- Columbia Forest uses soy-based adhesive in its PureBond® line

- Arauco is FSC-certified and LEED-compliant

- Canfor sources from certified Canadian forests

Specs matter when you’re exporting, especially with formaldehyde emission rules in the U.S. and Europe. I always check these first before placing large orders.

Where to Source Engineered Wood Panels for Furniture and Cabinet Projects?

I’ve worked with both local dealers and direct-from-factory channels. The right choice depends on order size, lead time, and product range.

You can source engineered wood panels in North America from local distributors, direct manufacturers, or global agents depending on your needs and volume.

Where Should You Buy From?

1. Local Distributors

- Great for fast delivery and small orders

- Can provide limited product variety

- Often higher prices

2. Manufacturer Direct (especially for export)

| Channel | Pros | Cons |

|---|---|---|

| Manufacturer Direct | Lower prices, full specs | Requires higher MOQ, slower lead |

| Global Agent | Can consolidate brands | Needs trust and clear contracts |

3. Online Sourcing Platforms

- Possible for sampling or trial orders

- Risk of inconsistent quality or rebranded products

When I work with overseas clients, I usually help them start with a sample box. Then we move to container-level orders once testing is done. It reduces risk and builds confidence.

Conclusion

If you’re sourcing panels for serious projects, it pays to know the brands. The right manufacturer brings you not just material—but peace of mind.