Edge banding looks small, but it decides how long your furniture stays good-looking and strong. Choose wrong, and repairs come sooner than you’d expect.

The most durable edge banding is typically made from PVC or ABS. These materials resist impact, heat, and moisture better than wood veneer or acrylic.

Furniture edges take daily hits—bags knock them, spills soak them, and heat from sunlight can warp them. That’s why edge banding isn’t just a design detail. It’s protection. If you’re building or sourcing furniture meant to last, then understanding material strength is where you start.

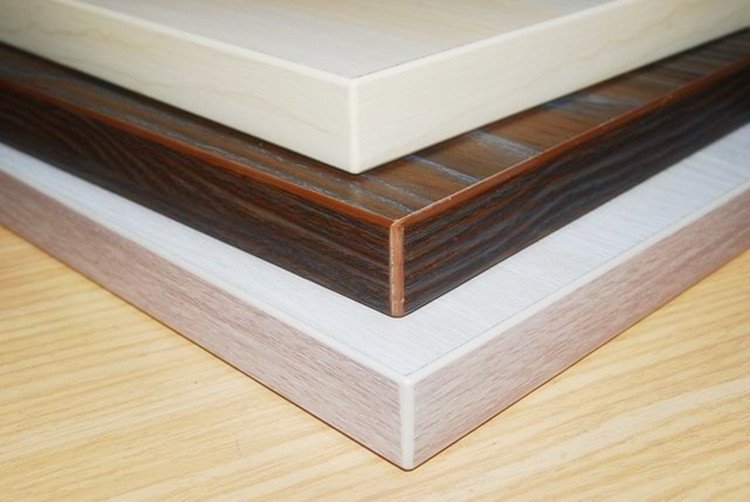

Comparing Common Edge Banding Materials: PVC, ABS, Acrylic, and Wood Veneer

Edge banding materials look similar, but their performance tells a different story.

PVC and ABS edge banding offer the best durability, while wood veneer and acrylic focus more on style or texture.

A Side-by-Side Look at Each Material

Here’s how they stack up:

| Material | Durability | Impact Resistance | Heat Resistance | Water Resistance | Common Use |

|---|---|---|---|---|---|

| PVC | High | Good | Moderate | High | Commercial & residential |

| ABS | High | Excellent | High | Moderate | High-end or eco-friendly use |

| Acrylic | Medium | Moderate | High | Medium | Gloss or color-focused styles |

| Wood Veneer | Low | Low | Low | Low | Traditional furniture |

Key Takeaways

- PVC is a workhorse. It’s reliable, flexible, and cheap.

- ABS is tougher and greener, with better heat tolerance.

- Acrylic looks sleek but needs careful handling.

- Veneer is beautiful but fragile.

If your priority is strength and lifespan, ABS or PVC will almost always win.

Why PVC Edge Banding Is Still the Most Popular Durable Choice?

PVC has been around for decades, and there’s a reason it still dominates.

PVC edge banding offers the best mix of cost, flexibility, and long-term durability, which makes it the first choice for mass furniture production.

What Makes PVC So Reliable?

- It bends easily. It fits curved edges without cracking.

- It’s waterproof. Spills don’t soak through.

- It’s affordable. You get protection without overspending.

Where I’ve Seen PVC Shine

I’ve worked with cabinet makers who won’t use anything else for kitchen units. One factory I partnered with switched from veneer to PVC after their warranty claims dropped by 40% in six months. That’s a clear sign of PVC’s long-term value.

But It’s Not Perfect

- Heat resistance is only average.

- Environmental concerns are rising due to its chemical base.

Still, for most uses, PVC hits the right balance.

When to Choose ABS or Acrylic for Extra Impact and Heat Resistance?

Sometimes, PVC just doesn’t cut it—especially in tough or high-heat environments.

ABS offers better environmental performance and stronger impact resistance, while acrylic works best for glossy, high-heat spaces.

ABS: The Tougher Cousin

- Eco-friendly: No chlorine, less toxic when recycled.

- High heat resistance: Great for near-oven panels or sunlit areas.

- Better for impact: Ideal for commercial settings.

One client who runs a school furniture line told me their switch to ABS helped reduce edge damage in student desks. That says a lot.

Acrylic: Bold but Brittle

- High gloss finish: It gives a luxury feel.

- Better for visuals: Matches high-end design trends.

- Needs precision: Harder to cut and bond than PVC or ABS.

Acrylic looks great on showroom pieces. But I’ve learned to warn customers about cracking if it’s used on furniture that gets moved around often.

Maintenance Tips That Prolong Edge Banding Life and Performance

Even the best edge banding won’t last if it’s not cared for.

To keep edge banding durable, clean it regularly, avoid heat exposure, and make sure it’s bonded properly from the start.

Installation Matters First

- Good glue equals longer life. Poor bonding is the #1 reason edge banding fails.

- Right temperature helps. Avoid cold surfaces during application.

Simple Ways to Keep It Looking New

| Tip | Why It Works |

|---|---|

| Clean with mild soap | Harsh cleaners break down adhesives |

| Use corner guards if needed | Prevent impact on high-traffic furniture |

| Avoid direct heat | Prolongs bond and prevents warping |

| Regular checks | Catch loose edges before full failure |

I’ve had clients complain about their edge banding peeling, only to find they used industrial degreasers on kitchen panels. A little gentle care goes a long way.

Conclusion

PVC is the most durable all-rounder, but ABS and acrylic edge banding win in specialized uses. Choose smart, and your edges will last for years.