Struggling with high defect rates on your line? I faced that too and learned the hard lessons fast.

Reliable PVC edge banding lowers rejects by ensuring consistent material, color, and adhesion from the start. This saves time, cut rework, and protects margins.

I’ll show what matters and what I check. Read on to reduce your factory defect rates on the next run.

How PVC Edge Banding Quality Directly Impacts Factory Defect Rates?

Worried that a bad spool will wreck an entire run? I was. Bad raw parts cause cascading failures.

High-quality edge banding means fewer peels, fewer bubbles, and fewer visible faults during finishing.

Dive deeper

I separate material issues into three groups: base resin & additives, dimensional tolerance, and surface finish. Each one links to specific on-line defects.

Base resin and additives

If the PVC mix is poor, the strip will age fast. Low-grade resin leads to yellowing, poor toughness, and weak adhesion. Suppliers that skimp on stabilizers or use inconsistent pigment batches produce strips that fail during hot-melt bonding or later in the field. Industry notes show discoloration and degradation often come from heat, oxygen, and improper stabilizers.

Dimensional tolerance and thickness

If thickness varies, the edgebander gun and glue won’t feed evenly. That causes gaps, under-bonding, or over-compression. Studies on edge banding performance point to thickness and feed speed as primary variables that affect peel strength. You will see more rejects when tolerances are loose.

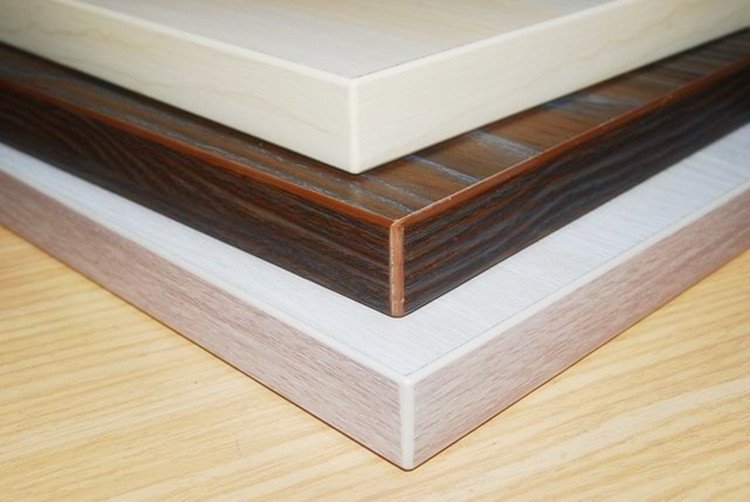

Surface finish and texture

A strip with wrong gloss or texture looks off even if it bonds. Texture mismatches hide or show seams differently. Suppliers who can’t control printing repeat and texture create parts that pass incoming inspection but fail visually after assembly. Online sources and adhesive makers note surface issues as frequent failure sources during bonding.

Practical checks I run

- I ask for a resin spec and stabilizer list.

- I measure thickness at 10 points across a sample roll.

- I run a quick hot-bond and peel test with our glue.

- I do a visual inspection under three light sources.

If any of these fail, I stop the order. These steps cut my initial defect spikes by a large margin.

Why Stable Color Matching and Surface Consistency Prevent Assembly-Line Rejects?

Color mismatch looks minor. In production it drives complaints and rework. I learned color is as operational as glue temperature.

Stable matches stop line holds from visual inspections and reduce sanding or rework after assembly.

Dive deeper

Color and surface consistency impact the line in three ways: first-article approvals, inline inspections, and final quality acceptance.

First-article and sample approval

If your supplier’s first sample is off, you delay the whole job. I always require a physical sample, not just a photo. For major decor systems like Egger, official decor codes and original chips are the authority. Relying on digital files causes mismatch later. Real samples let me test under production light and confirm texture.

Inline inspection pressure

When color shifts between rolls, operators stop the line to compare. This interruption costs minutes to hours per incident. If you buy from unreliable suppliers, these stops become daily. I track the number of line stops per week. After I switched to a better supplier, stops dropped substantially.

Final acceptance failures

Retail customers reject visible mismatches at inspection. That triggers rework like planing edges, repainting, or rejecting whole batches. Rework costs include labor, material, and lost throughput. Industry pieces note that poor supplier management can increase quality defect costs by up to 30% for some brands.

How I enforce stability

- I ask suppliers for gloss and texture codes.

- I set an acceptance ΔE number for color tolerance or require a supplier-provided tolerance.

- I require a small pilot run and measure color change across lots.

- I document lighting and viewing conditions for approvals.

These steps make color a controlled variable instead of a daily surprise.

How Reliable Suppliers Improve Production Efficiency and Reduce Rework Costs?

I treat suppliers as production partners. Good ones keep my line moving. Bad ones force rework loops that eat margin.

Reliable suppliers deliver consistent rolls, correct widths, and clean edges. That speeds machine set-up and reduces scrap.

Dive deeper

I look at three tangible ways supplier reliability reduces costs: set-up time, scrap rate, and rework burden.

Reduced machine set-up and downtime

When a supplier provides consistent width and edge quality, the edgebander needs fewer manual adjustments. I measured set-up time on several jobs. With consistent rolls, set-up dropped by 20–40% on average. The time back into production compounds across many jobs. Research on process optimization of edgebanding highlights feed speed, temperature control, and material consistency as key to stable peel strength and less stoppage.

Lower scrap and fewer rejects

Consistent edge banding reduces delamination and visible defects. Scrap parts not only waste material; they waste downstream labor. Studies show that rework and scrap account for a notable portion of manufacturing waste in furniture processes. I track defects-per-thousand and aim for less than 1% on incoming parts. Suppliers who meet this benchmark help me stay under target.

Simplified rework and claim handling

A reliable supplier has clear claims policies. They accept quick replacement or credit for defective lots. This reduces the internal time my team spends on investigations. I tie remedy terms to purchase orders. If the supplier resists clear remedies, I treat it as a service risk.

My practical test

I run a pilot PO of 1–2 pallets. I note set-up time, line stops, and scrap rate. If the supplier fails the pilot, I don’t scale. This pilot rule saved me from a costly long-term contract once.

How Strong QA Systems and Certifications Lower the Risk of Material Failures?

Certificates alone don’t fix problems. I use them as gatekeepers. Strong QA systems prove a supplier manages variation.

I check lab reports, ISO records, and audit findings before committing to volume.

Dive deeper

QA and certification fall into three areas: material safety and emissions, process quality systems, and third-party audits.

Material safety and emissions

For furniture markets, formaldehyde emissions and chemical safety matter. Regulations like CARB and national standards require specific limits for composite wood. I ask for test reports that match my

Process and quality systems

ISO 9001 is a baseline for process control. I look deeper. I want evidence the supplier tracks nonconformances, corrective actions, and batch traceability. Certificates without records mean nothing. I ask for corrective action logs or recent audit snapshots. This shows whether a supplier learns from problems.

Third-party factory audits

SMETA, BSCI, or customer audits reveal on-site practices. I request a recent audit and review open findings and closure dates. A clean audit with timely corrective actions reduces the chance of systemic manufacturing failures. If possible, I do a remote tour or hire a local auditor for a capacity/quality check.

How I apply QA in contracts

I make some certifications a contractual condition. I also require incoming inspection records for the first three lots. This forces the supplier to be accountable.

The Key Checks Buyers Should Run to Avoid High Defect Rates Before Choosing a Supplier?

You must test before you buy. I run the same checks every time. They catch 80–90% of future problems.

Short trials, lab tests, and clear claims rules protect production and profit.

Dive deeper

Below is a practical checklist I use. I break it into Material, Samples & Tests, Capacity & Delivery, and Commercial.

| Area | What I ask for | Why it matters |

|---|---|---|

| Material specs | Resin type, stabilizers, pigment batch, thickness tolerance | Ensures durability and consistent bonding |

| Samples | Physical color sample, texture sample, test strips | Confirms visual match and surface feel |

| Lab tests | Peel strength, thermal softening, VOC/formaldehyde report | Shows functional and compliance performance |

| Pilot run | 1–2 pallet pilot PO | Reveals real production behavior |

| Capacity proof | Machine counts, shift patterns, recent order examples | Confirms actual throughput |

| Certifications | CARB/TSCA, ISO 9001, SMETA/Sedex | Demonstrates compliance and process control |

| Claims & warranty | Written claim process, replacement rules, time windows | Limits your rework and cost risk |

| Pricing terms | Itemized costs, resin/pigment surcharge rules | Avoids hidden price volatility |

How I run tests

- I do a hot-melt adhesion test at the temperature of my edgebander.

- I do a peel test after 24 hours and after thermal cycling.

- I measure color under D65 and warm light and record ΔE where possible.

- I confirm supplier offers a sample chain for multiple decors.

If a supplier fails any step

I either renegotiate terms (like refundable sample fees or shorter initial MOQ) or move on. These checks made my defect rates predictable. They also made suppliers respond faster to issues because we had clear rules.

Conclusion

I run material, color, capacity, QA, and contract checks before every significant order. This prevents most defects and keeps my line moving.

Data sources and links

- Jowat — Failures in Edgebanding: The Most Frequent Causes and How to Solve Them. https://www.jowat.com/en-US/newsroom/detail/failures-in-edgebanding-the-most-frequent-causes-and-how-to-solve-them/ (jowat.com)

- Bioresources / NCSU — Effect of edge banding thickness, dowels, and adhesive types. https://bioresources.cnr.ncsu.edu/resources/effect-of-edge-banding-thickness-dowels-and-adhesive-types-on-withdrawal-strength-in-oriented-strand-board/ (bioresources.cnr.ncsu.edu)

- Bioresources — Optimization of edge banding process parameters. https://bioresources.cnr.ncsu.edu/resources/optimization-of-edge-banding-process-parameters-used-for-particle-board-and-medium-density-fiberboard/ (bioresources.cnr.ncsu.edu)

- California Air Resources Board (CARB) — Composite Wood Products program. https://ww2.arb.ca.gov/our-work/programs/composite-wood-products-program. (ww2.arb.ca.gov)

- Trace for Good — The true cost of quality defects and supplier management. https://www.traceforgood.com/blog/the-true-cost-of-quality-defects-how-poor-supplier-management-eats-into-your-margins. (traceforgood.com)

- Veridion — 14 Key Metrics for Assessing Supplier Performance. https://veridion.com/blog-posts/supplier-performance-metrics/ (Veridion)

- Thomasnet — What Is Supplier Defect Rate? Definition and Examples. https://www.thomasnet.com/insights/supplier-defect-rate/ (thomasnet.com)

- PVC Decorative Film — Maintaining color stability in PVC edge banding. https://pvcdecorativefilm.com/maintaining-color-stability-in-pvc-edge-banding-over-time/ (pvcdecorativefilm.com)

- ResearchGate / Furniture rework studies — Rework Reduction and Quality Cost Analysis. https://www.researchgate.net/publication/343183314_Rework_Reduction_and_Quality_Cost_Analysis_of_Furniture_Production_Processes_Using_the_House_of_Risk_HOR. (ResearchGate)