I worry when material deliveries are late. I watched a line stop and costs spike.

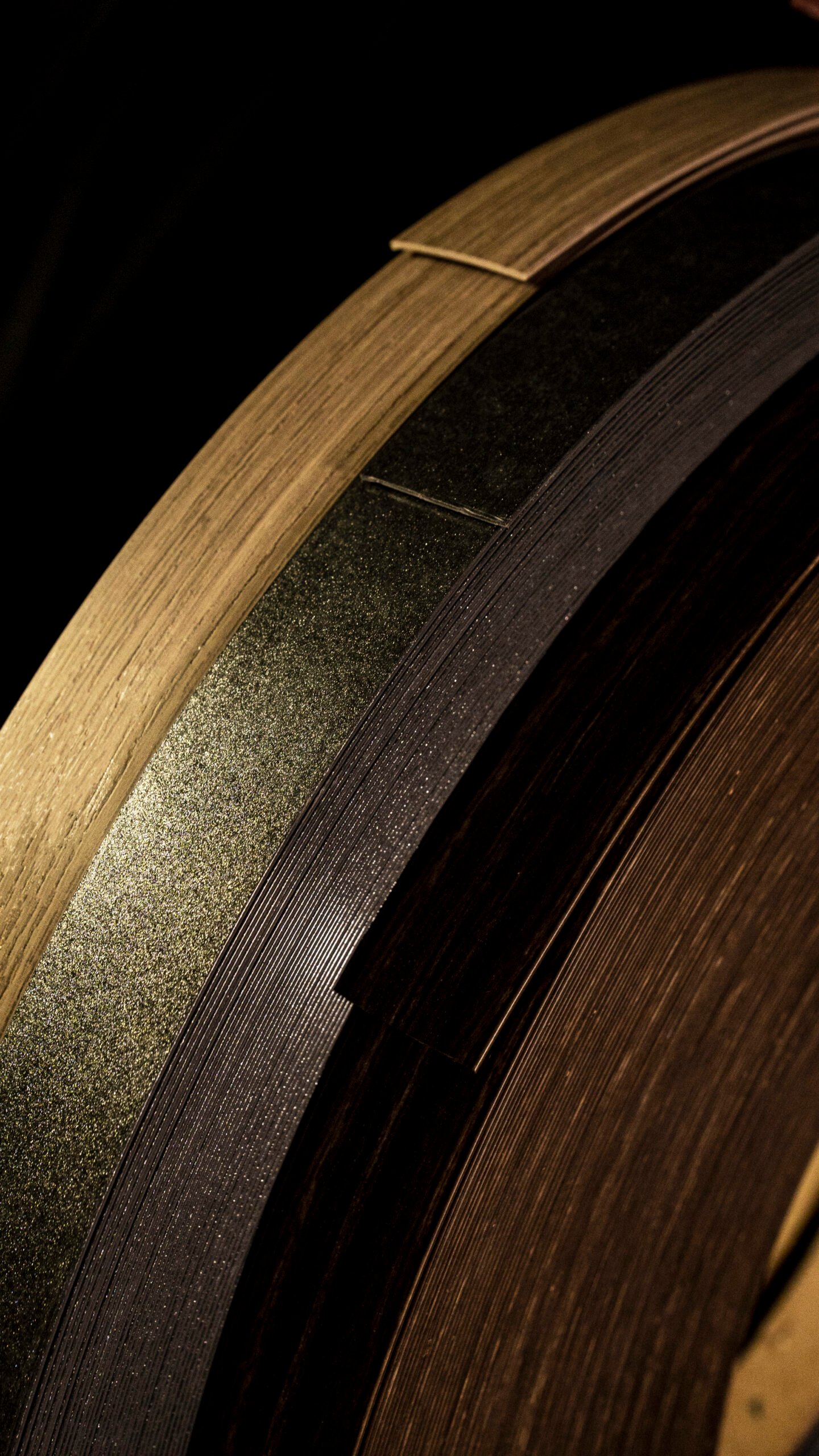

Reliable PVC edgeband supply keeps production steady, lowers scrap, and protects project schedules and margins. This short guide shows where supply breaks cause the biggest pain and what I check before I buy.

I want you to stay with me. I will walk through the main risks. I will give practical checks you can use right away. These are the things I use when I vet suppliers and run pilots.

How an Unstable Edgeband Supply Disrupts Panel Furniture Production?

I once had a week where three rolls arrived late. The line stopped. Workers waited. Customers pushed for compensation.

Unstable edgeband supply creates downtime, forces order reshuffles, and raises rush shipping costs. Small shortages quickly become large schedule problems.

Dive deeper — real line impacts and how I measure them

Production teams hate uncertainty. I track three simple metrics to see the impact of supply instability: downtime minutes, order reschedules, and rush freight costs. I recommend you track the same. These numbers make the problem clear to procurement and finance.

Where instability shows up

- Line stops. When a roll is late, the edgebander stops. The set-up for the line takes time. That lost time is labor cost.

- Order reshuffle. Late tape forces us to change production order. That creates extra handling and mistakes.

- Rush shipping. We sometimes pay for air freight or last-mile express to fix gaps. That is expensive.

- Buffer stock cost. To avoid stoppages, we hold safety stock. That ties up cash and space.

- Quality inconsistency in emergency buys. When we rush-buy from unfamiliar vendors, quality issues rise. That raises scrap and rework.

I measure these with a weekly log. The log shows minutes of downtime per month and extra freight per quarter. In my experience, a single two-hour line stop costs far more than the price difference between cheap and reliable edgeband. Industry sources highlight similar risks and advise proper supplier assessment and buffer planning.

Quick actions I take

- Require lead-time confirmation with penalties for repeated misses.

- Keep minimum safety stock sized to cover average lead-time variance.

- Approve a short list of backup suppliers who pass basic QC tests.

These steps cut my emergency buys by half. They also make my production planning more stable.

The Hidden Costs of Inconsistent PVC Edgeband Quality?

I once accepted a low-price batch. The next week, blemishes and delamination rose. I paid for rework and a customer refund.

Inconsistent quality raises invisible costs: scrap, rework, extra labor, machine maintenance, and customer claims. Unit price alone hides these expenses.

Dive deeper — cost buckets and how I quantify them

Price per meter is easy to compare. Total cost is harder. I break total cost into clear buckets. That helps me compare offers fairly.

Primary cost buckets

- Material cost. The invoice price per roll.

- Scrap cost. Wasted panels and edge tape that cannot be used.

- Rework labor. Time to remove and reapply edges or to sand and fix.

- Machine downtime cost. Lost minutes when machines need clearing or resetting.

- Warranty and claims. Refunds, new shipments, and field labor for replacements.

- Logistics and admin. Extra handling, packaging, and customer service time.

I run a simple spreadsheet for a pilot batch. I record scrap rate, rework hours, and downtime minutes. Then I calculate the effective cost per finished panel. In my cases, a cheaper tape with a higher scrap rate often doubled the effective cost. I also saw that poor quality increased machine wear. Jams and abrasive failures cause maintenance trips. Those trips lower line throughput over weeks. Industry guides note that adhesive mismatch, uneven thickness, and poor surface finish are the typical drivers of these hidden costs.

A practical table I use

| Cost type | How I measure it | Why it matters |

|---|---|---|

| Scrap | Panels scrapped per 1000 | Direct material loss |

| Rework | Labor hours per 1000 panels | Adds cost and delays |

| Downtime | Minutes per week | Reduces throughput |

| Warranty | Replacement shipments per year | Hit to cash and reputation |

| Extra freight | $ per emergency shipment | Sudden expense |

This breakdown makes it easy to sell the premium option to managers. Data beats feelings in procurement meetings. It also helps me decide when to run a pilot or when to stop a supplier.

Why Color and Specification Consistency Matters for Large-Scale Furniture Projects?

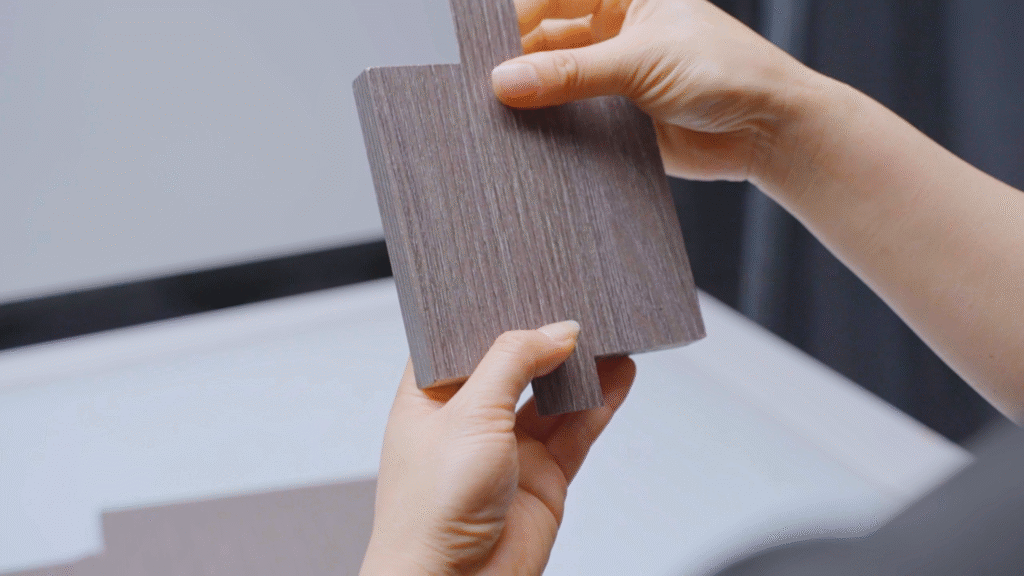

I managed a 2,000-piece job once. The edgeband shade did not match across batches. Installers returned parts. The contractor delayed payment.

Color mismatch and spec drift cause visible rejections on large projects. Consistency keeps assembly smooth and avoids costly rework and client disputes.

Dive deeper — batch control, tracking, and tests I require

Large projects expose small differences. I require strict batch control from suppliers. I also run quick checks before we start a large run.

Why consistency matters

- Aesthetics. Visible shade or sheen differences cause client rejections.

- Fit and function. Thickness variance changes trimming and joining tolerances.

- Ordering logistics. Multi-batch projects need consistent performance over time.

Supplier information I demand

- Batch codes and production dates. I log these and compare later.

- Thickness tolerance statement. I want a numeric tolerance, for example ±0.05 mm.

- Color batch samples. I store a small sample with the order record.

- Surface finish spec. Matte, gloss level, and texture details.

I run three simple tests on arrival:

- Visual match under a light box. I compare new rolls to retained samples.

- Calliper thickness check. I sample every 10 m for big rolls.

- Adhesion trial. I run a 10-piece bond test, trim, and simulate stacking.

For large projects, I also require suppliers to commit to longer batch runs or to provide a continuous batch sequence. This prevents mid-project shifts. Market reports show that demand for consistent, high-quality edgebands is rising in large furniture sectors.

How Reliable Edgeband Supply Reduces Lead Times and Production Risk?

I used to have a long approval loop for new tape. That slowed new SKUs. After streamlining, lead times shrank and we shipped faster.

Reliable supply shortens lead time variance and reduces the need for emergency fixes. That improves on-time delivery and lowers total project risk.

Dive deeper — processes to tighten supply and lower risk

Reducing lead time risk is about both supplier choice and internal process. I focus on three areas: supplier capability, predictable ordering, and quick validation.

Supplier capability

- Ask for historical lead time data. Good suppliers track it.

- Check production capacity during your peak months.

- Verify quality control processes at the mill.

Predictable ordering

- Use rolling forecasts with suppliers. These forecasts reduce surprises.

- Place staggered orders to avoid single-point failure.

- Negotiate minimal batch commitments that match your runs.

Quick validation

- Use a fixed incoming inspection routine. Sample and test the first roll of every batch.

- Approve “fast track” use for trusted suppliers after a positive pilot.

I run a 30-day supplier scorecard. It tracks on-time delivery and quality incidence. Suppliers with high scores get priority scheduling. This simple approach lowered my emergency freight spend and cut line stops. Industry advice recommends pilots and small-scale validation before full adoption to avoid large disruptions.

What Manufacturers Should Look for in a Dependable Edgeband Supplier?

I now vet suppliers with a checklist. It saves time. It prevents surprises.

Choose suppliers who provide clear specs, batch traceability, test data, stable lead times, and responsive support. Those traits reduce surprises and protect margins.

Dive deeper — a practical supplier checklist and trial plan

I use a short checklist when I evaluate a new supplier. I also require a small pilot before full-scale buy.

Supplier checklist

- Documentation: Thickness tolerance, adhesive type, coating weight, and color formula.

- Traceability: Batch codes and production dates on every roll.

- Test reports: Peel strength, abrasion, and UV stability results.

- Sample support: Free or low-cost roll samples for validation.

- Capacity & lead times: Confirmed production slots for peak season.

- Warranty & replacement policy: Clear terms for defects and claims.

- Technical support: Access to a tech rep for machine setup.

Pilot plan I run

- Order 2–3 small rolls as samples.

- Run a 500–1,000 panel pilot at normal speed.

- Log scrap rate, rework hours, and any machine stops.

- Hold samples for later color and adhesion checks.

- Compare pilot results to your internal benchmarks.

A short results table I use

| Metric | Acceptable threshold | Pilot result |

|---|---|---|

| Scrap rate | < 1.5% | (record) |

| Rework hours | < 2 hrs / 1,000 panels | (record) |

| Downtime | < 30 mins / week | (record) |

| Peel test | > industry spec | (record) |

If the pilot passes, I scale orders slowly. If it fails, I request corrective actions or walk away. This approach saved me money and saved client relationships.

Conclusion

I trust suppliers who prove consistency. That choice keeps my lines running and my customers happy.

Data sources I used while writing (click to open):

- Jowat — “Failures in Edgebanding: The Most Frequent Causes and How to Solve Them.”

https://www.jowat.com/en/newsroom/detail/failures-in-edgebanding-the-most-frequent-causes-and-how-to-solve-them/ (jowat.com) - Verified Market Reports — “Thermoplastic Furniture Edgebands Market Insights.”

https://www.verifiedmarketreports.com/product/thermoplastic-furniture-edgebands-market/ (Verified Market Reports) - Bioresources (BRJ) — “Effect of edge banding thickness, dowels, and adhesive types on withdrawal strength.”

https://bioresources.cnr.ncsu.edu/resources/effect-of-edge-banding-thickness-dowels-and-adhesive-types-on-withdrawal-strength-in-oriented-strand-board/ (bioresources.cnr.ncsu.edu) - BESTIN Group — “Edge Banding Completed Guide” (hot-melt and PUR guides).

https://www.bestingroup.com/edge-banding-completed-guide/ and https://www.bestingroup.com/pur-edge-banding-the-definitive-guide/ (bestingroup.com) - Wood & Panel — “Top reasons for edgebanding failures and how to fix them.”

https://www.woodandpanel.com/woodnews/article/top-reasons-for-edgebanding-failures-and-how-to-fix-them/ (woodandpanel.com)