Struggling to decide between wood veneer and laminate for your furniture project? You’re not alone. This comparison has confused furniture buyers and makers for years.

Wood veneer is made from real wood, while laminate is a synthetic product. Veneer offers natural beauty; laminate offers durability and affordability.

If you’re designing, sourcing, or manufacturing furniture, this choice affects cost, performance, and your brand image. Let’s break it down step by step so you can make the right call.

What Are Wood Veneer and Laminate?

Ever felt overwhelmed by materials when designing furniture? I have. Veneer and laminate might look similar at first, but their origins and structures are very different.

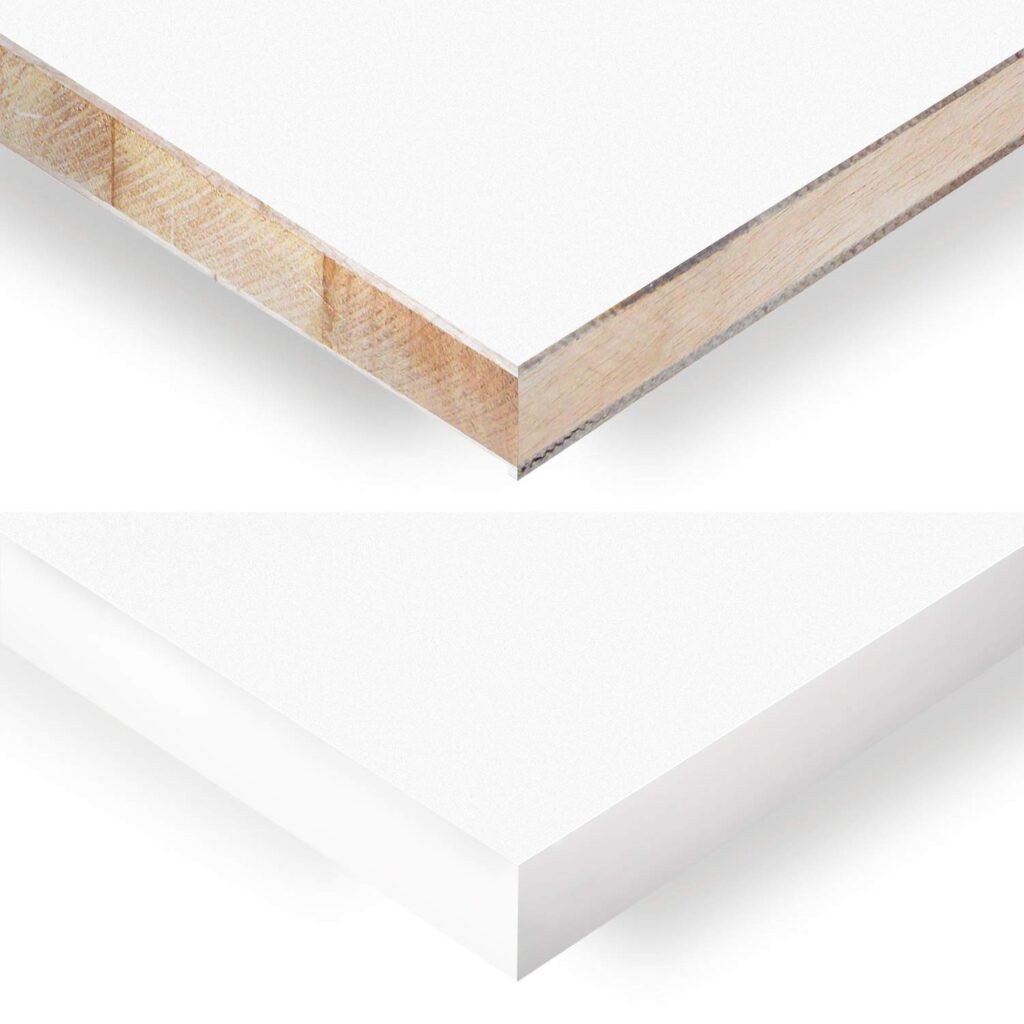

Wood veneer is a thin layer of real wood glued onto a base panel. Laminate is a printed surface made from plastic resins and paper fused together under heat and pressure.

Understanding the Basics

Before we compare them, let’s look at what each material really is.

Wood Veneer

Wood veneer is made by slicing real logs into thin sheets. These sheets are glued onto materials like MDF or particleboard. Since veneer comes from natural wood, each sheet has unique grain patterns. This gives furniture a high-end, real-wood look.

Laminate

Laminate is an artificial surface. It’s created by compressing layers of paper or fabric with plastic resins like melamine. The top layer is a printed pattern—often a wood design. It’s applied to the same kind of base boards, but the final look is more uniform.

| Feature | Wood Veneer | Laminate |

|---|---|---|

| Made of | Real wood | Printed surface + resin |

| Appearance | Natural grain, unique | Uniform, can mimic any texture |

| Base Material | MDF, plywood, particle board | MDF, plywood, particle board |

| Feel | Warm, authentic | Smooth, sometimes cold |

Key Differences Between Veneer and Laminate Materials?

Not all materials are created equal—even if they look the same. Choosing wrong could cost you quality or profit.

The key differences include cost, durability, moisture resistance, appearance, and maintenance. Veneer is natural and elegant; laminate is stronger and easier to care for.

Where It Really Matters

Here are the key areas where veneer and laminate diverge:

1. Durability

Laminate wins here. It’s scratch-resistant, moisture-resistant, and handles wear better. Veneer is softer and can get damaged more easily if not treated properly.

2. Cost

Laminate is generally cheaper. Veneer is pricier because it’s real wood and needs more care in production and handling.

3. Look and Feel

Nothing beats the warmth and uniqueness of real wood. Veneer shows off real grain. Laminate, though printed, can imitate many patterns well.

4. Maintenance

Laminate is easier. You can wipe it with a damp cloth and not worry. Veneer needs more careful cleaning to avoid stains or damage.

| Property | Veneer | Laminate |

|---|---|---|

| Scratch Resistance | Low | High |

| Water Resistance | Medium (needs sealing) | High |

| Price Range | Medium to High | Low to Medium |

| Visual Variety | Unique per piece | Repeatable prints |

| Repairs | Can be refinished | Needs replacement |

Pros and Cons: Which One Suits Your Furniture Project Better?

Choosing materials without knowing the trade-offs is like buying shoes without knowing your size. It may look good—but won’t work long term.

Veneer is perfect for premium furniture with a natural look. Laminate is ideal for budget projects, commercial use, or modern designs with repeat patterns.

Know What You’re Trading Off

Let’s weigh the pros and cons of each side-by-side.

Wood Veneer

Pros:

- Real wood texture

- Premium appearance

- Can be sanded and refinished

Cons:

- Sensitive to scratches

- More expensive

- Needs regular care

Laminate

Pros:

- Scratch and water-resistant

- Affordable

- Many patterns available

Cons:

- Looks artificial

- Can’t be refinished

- May chip at the edges

Think of veneer like a handmade table—it has charm and character. Laminate is more like a reliable work desk—practical, consistent, and durable. Both are valuable—it depends on your project needs.

Applications: Where to Use Veneer vs Laminate in Furniture Design?

Even the best material fails if it’s used in the wrong place. The key is to match the material to the space and function.

Use veneer in living rooms, bedrooms, or executive furniture. Use laminate in kitchens, offices, and high-traffic areas where durability matters most.

Room by Room Guide

Let me walk you through how I guide clients on choosing materials for different applications:

Living Room

Veneer works beautifully. It gives warmth, natural feel, and adds a premium look to coffee tables, media consoles, and shelves.

Kitchen

Laminate is better. It handles heat, water, and oil better than veneer. Cabinets and countertops made from laminate are easy to clean.

Office Furniture

Laminate again. Office desks, filing cabinets, and workstations need to resist scratches and wear. Laminate does this well.

Bedroom

This depends. For headboards and wardrobes, I often suggest veneer if budget allows. It adds richness without needing to withstand rough use.

| Space | Best Material | Reason |

|---|---|---|

| Kitchen | Laminate | Moisture and heat resistance |

| Living Room | Veneer | Visual warmth and elegance |

| Office | Laminate | Durable and cost-efficient |

| Bedroom | Veneer (if budget) | Luxurious look, lower usage stress |

Veneer or Laminate — How to Make the Right Choice for Your Business?

You don’t just need a good material. You need the right material for your product, price point, and brand.

Choose veneer if you’re targeting premium customers. Choose laminate if your market values price, volume, and performance.

How I Guide Clients

When working with furniture manufacturers, I ask them three things:

- Who is your target customer?

If they sell to high-end homes or designers, I recommend veneer. - What’s the expected usage environment?

If it’s high-traffic or commercial (like a hotel), laminate makes more sense. - What’s your budget and lead time?

Laminate is cheaper and easier to scale. Veneer needs more skill and care in production.

I also talk with sourcing managers. If they’re concerned about cost, I suggest starting with laminate for basic models, and offering veneer as an upgrade option. This works well in markets like the Middle East and Southeast Asia.

| Factor | Choose Veneer When… | Choose Laminate When… |

|---|---|---|

| Customer Type | High-end, custom-focused | Mass-market, price-sensitive |

| Usage Intensity | Moderate (home, display furniture) | Heavy (kitchen, office, hotel) |

| Budget | Flexible | Tight |

| Supply Chain | You can manage longer production cycles | You need fast, repeatable output |

Conclusion

Both veneer and laminate have their place. Your customer, product, and budget decide which one wins.