Have you ever noticed that edge banding on door frames looks different from the ones on tables? This can cause confusion when choosing materials.

Door frame edge banding and table edge banding serve different purposes and have key differences in design, material, and durability to match their specific furniture uses.

Understanding these differences helps you pick the right edge banding for your projects. Let’s dig deeper.

Definition and Purpose: Door Frame Edge Banding vs Table Edge Banding?

Choosing the right edge banding starts with knowing what each type is and why it exists.

Door frame edge banding is designed to cover and protect door edges, while table edge banding focuses on durability and comfort for horizontal surfaces.

What is Door Frame Edge Banding?

Door frame edge banding covers the vertical or angled edges of cabinet doors or furniture frames. It protects edges from damage and moisture and improves the look.

What is Table Edge Banding?

Table edge banding is applied to horizontal surfaces like tabletops. It must resist wear, impact, and feel comfortable to touch. It often has rounded profiles for safety.

| Feature | Door Frame Edge Banding | Table Edge Banding |

|---|---|---|

| Location on Furniture | Vertical/angled edges | Horizontal surfaces |

| Main Purpose | Protection and decoration | Durability and comfort |

| Edge Profile | Usually sharp or slight round | Often rounded or beveled |

Knowing these basics helps decide which banding suits your needs.

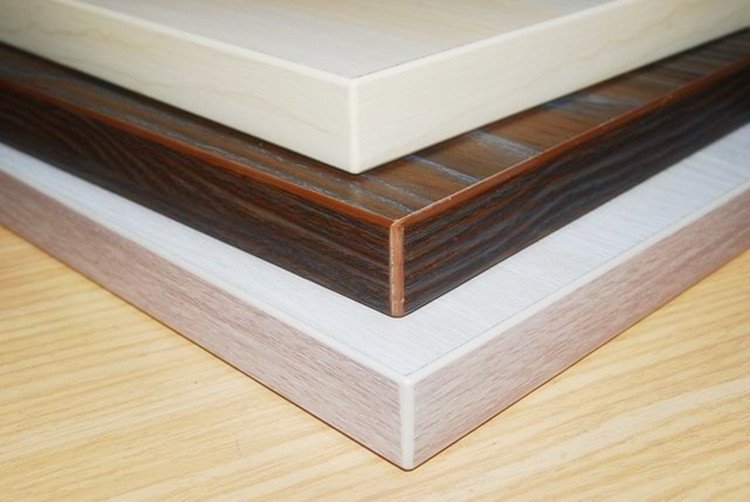

Material and Thickness Differences Between Door Frame and Table Edge Banding?

Materials and thickness vary because door frames and tables face different challenges.

Door frame edge banding usually uses thinner, rigid materials, while table edge banding requires thicker, tougher tapes to withstand wear and impacts.

Typical Materials Used

- Door Frame Edge Banding: PVC or ABS with moderate thickness, enough to protect but keep sharp edges.

- Table Edge Banding: Thicker ABS or wood veneer for strength and smooth feel.

Thickness Comparison Table

| Banding Type | Common Thickness Range (mm) | Material Examples |

|---|---|---|

| Door Frame Banding | 0.4 – 1.0 | PVC, ABS |

| Table Banding | 1.0 – 2.5 | ABS, Wood veneer |

Thicker tape on tables helps absorb impacts and prevent chipping, which is less critical for door frames.

Durability and Wear Resistance: Why Door Frame and Table Edge Banding Differ?

Tables get more daily use and contact, so their edge banding must last longer and resist damage better.

Door frame edge banding focuses more on protecting from moisture and scratches, while table edge banding is made to resist heavy wear, impact, and heat.

Key Differences in Durability Needs

| Aspect | Door Frame Edge Banding | Table Edge Banding |

|---|---|---|

| Wear Resistance | Moderate | High |

| Impact Resistance | Low to moderate | High |

| Heat Resistance | Standard | Often enhanced |

| Moisture Resistance | Important | Important |

Furniture makers should choose materials based on where the piece will be used and how it will be handled daily.

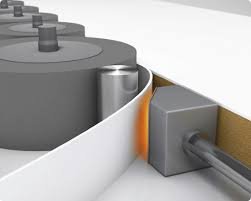

Installation Methods and Techniques for Door Frame and Table Edge Banding?

Installation varies because of shape and material differences.

Door frame banding usually needs precise cutting and gluing for clean sharp edges, while table banding often requires flexible heat or laser technology for smooth rounded edges.

Installation Comparison

| Step | Door Frame Edge Banding | Table Edge Banding |

|---|---|---|

| Cutting Method | Straight cuts with sharp angles | Rounded or beveled cutting |

| Adhesive Type | Standard hot-melt glue | Laser or PUR glue for flexibility |

| Machine Used | Basic edge banders | Advanced laser edge banders |

| Finishing | Trimming and sanding | Buffing and polishing |

The right installation process ensures a strong bond and good appearance.

How to Choose the Right Edge Banding for Your Furniture Project: Door Frame or Table?

Choosing edge banding depends on your furniture’s use, design, and durability needs.

Match the edge banding type to the furniture part: door frames need thinner, moisture-resistant banding, while tables require thicker, tougher banding for daily wear.

Selection Tips

- For cabinet doors, focus on precise, sharp edge protection.

- For tables, choose thick, rounded, and impact-resistant banding.

- Consider color and texture matching for a uniform look.

- Test samples to check compatibility with your materials and machines.

| Furniture Part | Recommended Banding Type | Key Features Needed |

|---|---|---|

| Door Frames | Thin PVC/ABS, sharp edges | Moisture resistant, clean look |

| Tables | Thick ABS/wood veneer, rounded | High durability, smooth finish |

I always test different bandings before large orders. It saves time and guarantees quality.

Conclusion

Door frame and table edge bandings differ in design, material, durability, and installation. Choose based on your furniture’s use to get the best results.