I see buyers and makers pick PVC again and again. They worry about cost, look, and production speed. I felt the same at first.

PVC remains the go-to edgeband because it balances cost, flexibility, and consistent finish for mass furniture production. This makes it ideal for high-volume manufacturing and wide market demand.

I will walk you through why PVC still leads. I will show the core advantages, real production reasons, and the market signals. Read on if you buy, make, or specify edgebanding.

The Core Advantages That Keep PVC Edgeband Ahead of Other Materials?

I remember being surprised by how many shops used PVC. They all had similar reasons: low cost, wide colors, and easy supply.

PVC offers a mix of low raw material cost and mature production tech. This keeps price stable versus other materials. PVC also gives many surface effects. It can mimic wood, stone, metal, or matte finishes while remaining affordable. For many factories, this means they can meet design demands without raising unit cost.

What I see in practice

- PVC is cheaper than ABS and acrylic for the same visual effect. This matters for bulk orders.

- PVC extrusion lines are widely available. This reduces lead times and vendor risk.

- PVC offers wide color matching and reliable repeatability. This helps large furniture runs keep consistent looks.

Quick comparison table

| Feature | PVC | ABS | Acrylic |

|---|---|---|---|

| Cost | Low | Higher | High |

| Flexibility | High | Medium | Low |

| Color variety | Very high | High | High |

| Heat resistance | Lower | Higher | Medium |

| Recyclability | Lower | Higher | Varies |

This table shows why many choose PVC for cost-focused projects. It also shows when ABS or acrylic may be better (e.g., high-heat or green-spec projects).

How PVC Edgeband Balances Cost, Durability, and Aesthetic Consistency?

I always ask suppliers for raw cost breakdowns. The numbers often explain choices.

PVC raw resin cost is lower than many thermoplastics. That lowers per-meter price. At scale, savings add up fast. In factories that produce millions of meters yearly, even small price gaps matter. Market reports show PVC continues to dominate in many regions because of this price-performance ratio.

Durability vs cost

PVC performs well under normal use. It resists moisture and abrasion enough for kitchens and bedrooms. It is not the best for extreme heat or heavy-impact zones. Still, for standard furniture, PVC often meets life-expectancy needs while keeping costs low.

Aesthetic consistency

Producers can control color and gloss during extrusion. That gives stable batches. For large projects, this reduces visible variation. That stability is a major reason designers and buyers stick with PVC.

Why Modern Manufacturers Prefer PVC for Mass Production Efficiency?

I visited a mid-size factory. Their edgebanding line ran long shifts. PVC made their life simple.

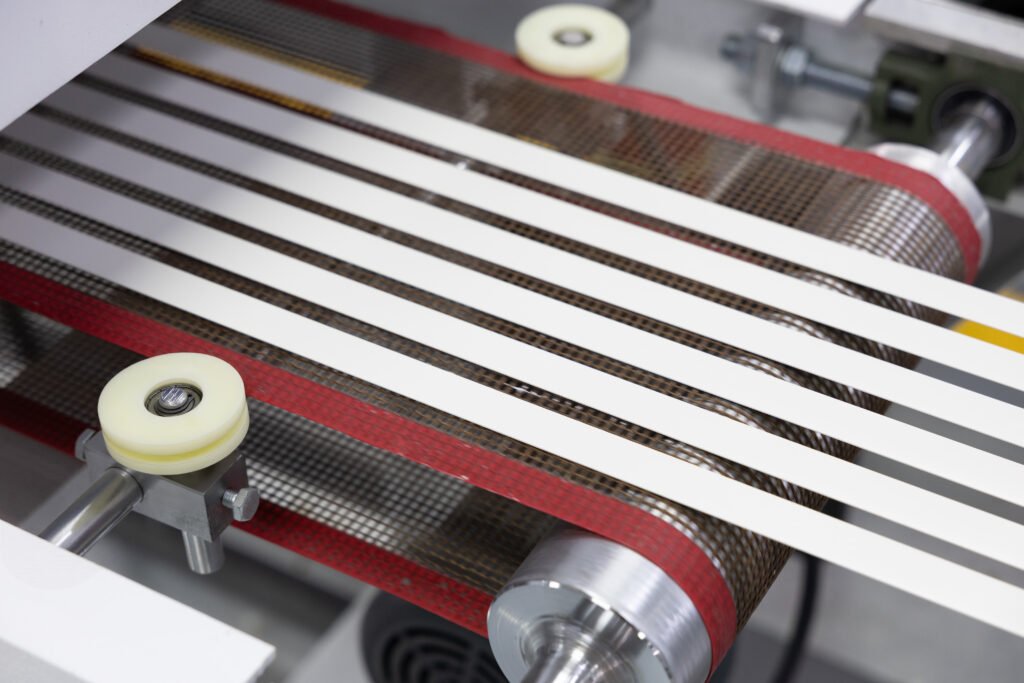

PVC extrusion and slitting lines are mature. Machines and tooling are common and cheap. Operators know the process. That lowers training time and error rates. Less downtime means faster output and fewer rejects. This advantage is huge in mass production.

Production workflow benefits

- Fast setup for common widths (e.g., 22 mm, 32 mm).

- Fewer specialty adhesives or unusual bond temps.

- Easy trimming and finishing with standard knives.

Productivity numbers (industry signals)

Market studies report steady growth in the edge banding market and stable demand for PVC edgeband in cabinetry and modular furniture. Manufacturers rely on PVC to meet large orders with predictable lead times.

Market Trends Showing the Continued Dominance of PVC Edgebanding?

I track reports and supplier news. PVC shows steady demand across regions.

Industry forecasts put the global edge banding materials market in a steady growth path through the decade. Thermoplastic edgebands (PVC included) make up a large share of that market. Growth is driven by rising furniture output, modular design trends, and demand for affordable finishes. These drivers favor PVC because of its price and design flexibility.

Regional notes

- Asia remains a major production hub for PVC edgeband, due to resin supply and manufacturing scale.

- Europe and North America show growing interest in ABS for greener specs, but PVC still serves most mainstream furniture needs.

What this means for buyers

Buyers can still access many PVC suppliers. That gives choice and competitive pricing. If you need more eco-friendly materials, expect a slightly higher cost and possibly longer lead times.

Key Application Scenarios Where PVC Outperforms Alternative Edgebands?

I choose PVC when I want balance. Here are scenarios where PVC shines and when another material fits better.

Best-fit scenarios for PVC

- Residential casegoods and cabinets where cost control matters.

- Large-volume flat-pack furniture to keep consistent finish.

- Moisture-prone interior zones (bathroom furniture with careful adhesive choice).

When to choose ABS or acrylic instead

- Childcare or medical furniture needing higher impact resistance — pick ABS.

- High-gloss, mirror-like faces where acrylic may give a superior look.

- Projects requiring specific environmental certifications may steer away from PVC.

Practical checklist for buyers

- Define the environment (kitchen, bedroom, office).

- List the required durability level.

- Check budget per linear meter.

- Confirm color and gloss match with samples.

- Ask about lead times and production batch repeatability.

This checklist helped me avoid costly returns and mismatches on several projects.

Conclusion

PVC keeps leading because it hits the sweet spot of cost, flexibility, and reliable supply for mass furniture production.

Data sources and links

- Transparency Market Research — Global Edge Banding Materials Market (2023 report).

https://www.transparencymarketresearch.com/global-edge-banding-materials-market.html - Reports and Data — Thermoplastic Edgeband Market (market overview). (Reports and Data)

https://www.reportsanddata.com/report-detail/thermoplastic-edgeband-market - Fortune Business Insights — Edge Banding Materials Market analysis. (Fortune Business Insights)

https://www.fortunebusinessinsights.com/edge-banding-materials-market-111502 - Protecnic — PVC edging industry overview. (Protecnic)

https://protecnic.es/en/canteado-pvc/ - EdgebandCT — PVC vs ABS comparison and market notes. (Edge Band CT)

https://edgebandct.com/global-edge-banding-market-size-and-forecast-2025-2032/

https://edgebandct.com/pvc-vs-abs-edge-banding-for-wood-panels/